Thrust bearing for a shaft, particularly for the shaft of a water turbine

A technology for thrust bearings and bearing rings, applied to shafts and bearings, rotating bearings, bearings, etc., can solve the problems of continuous damage, vulcanization damage, loss of elasticity, etc., and achieve the effect of simple manufacturing method and prevention of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

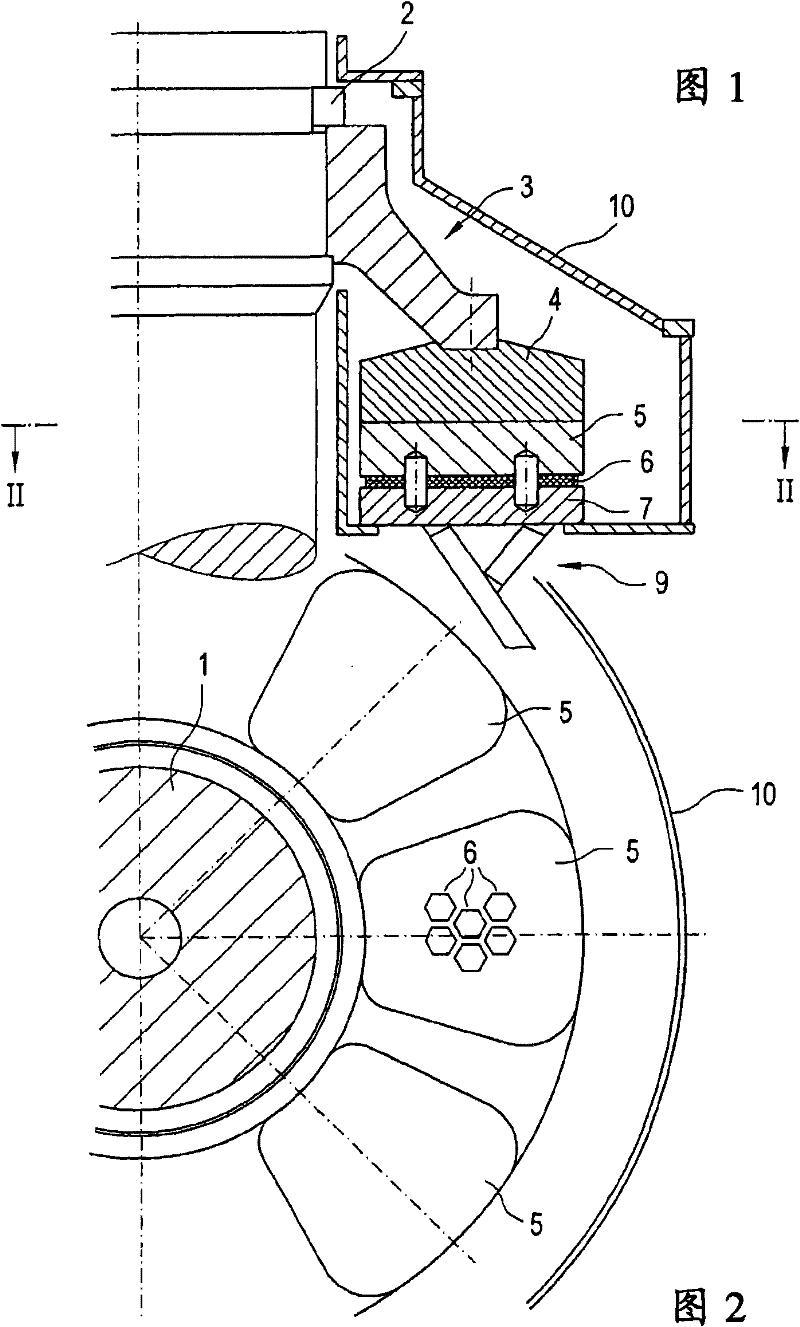

[0024] exist figure 1 Shaft 1 with vertical axis 1.1 can be seen in . This shaft is surrounded by a collar 2 . The collar 2 is supported by a collar sleeve 3 which surrounds the shaft 1 . The lower end of the collar sleeve 3 rests on a thrust ring 4 which likewise surrounds the shaft 1 . The thrust ring 4 itself rests itself on a plurality of bearing seats 5 which are arranged at regular intervals around the shaft 1 .

[0025] The spring element 6 follows. These spring elements rest on the bearing ring 7 . The pins 8 engage in the bores of the bearing seat 5 and of the bearing ring 7 . The bearing structure 9 supports the bearing ring 7 . The housing 10 surrounds the collar 2 , the collar sleeve 3 , the thrust collar 4 , the bearing seat 5 , the spring element 6 and the bearing ring 7 .

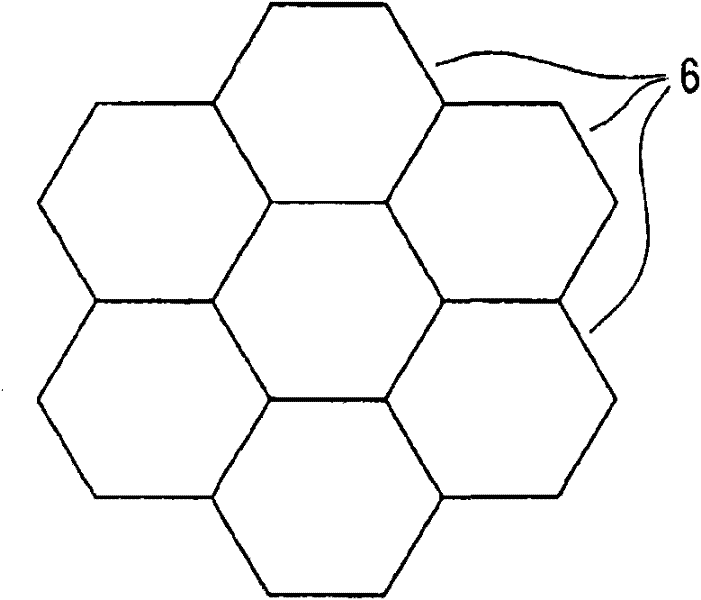

[0026] exist figure 2 The configuration of the spring element is explicitly shown in . As can be seen here are hexagonal flakes.

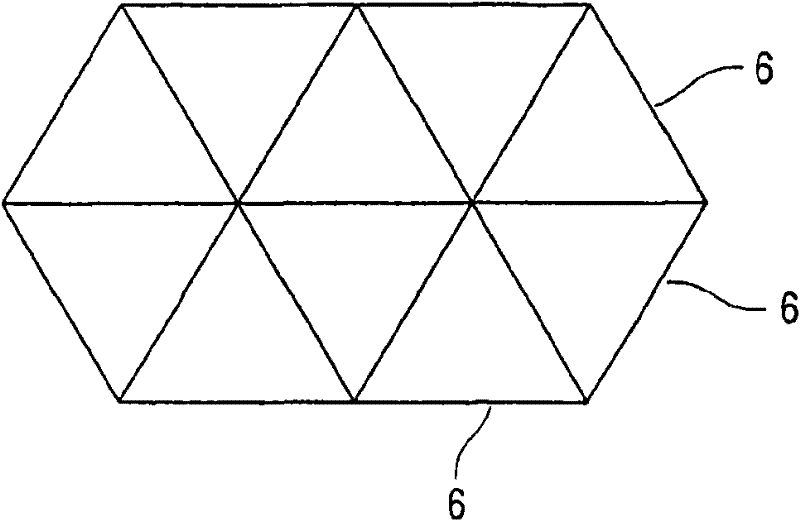

[0027] The spring elements do not necessarily hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com