Cathode material of hollow-cathode lamp and preparation method thereof

A hollow cathode lamp and cathode material technology, which is applied to the parts and components of gas discharge lamps, can solve the problems of low melting point, easy sublimation, and low energy, and achieve the effect of overcoming mutual interference and improving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A cathode material for a hollow cathode lamp, the cathode material is composed of AgSe alloy, the percentage content of Se in the AgSe alloy is 55%, and the percentage content of Ag is 45%.

[0019] A method for preparing a cathode material of a hollow cathode lamp, the method steps are as follows,

[0020] (1) Take metallic silver and metallic selenium (metallic silver and metallic selenium are block, and purity is all greater than 99.99%), mix by above-mentioned ratio;

[0021] (2) Put the mixture into the quartz crucible, put the crucible into the melting equipment, and evacuate until the vacuum degree is less than 10 -3 Pa;

[0022] (3) Heating the mixture to 1300° C., melting the raw materials, stirring, melting for 60 minutes, and cooling with the furnace to obtain the AgSe alloy.

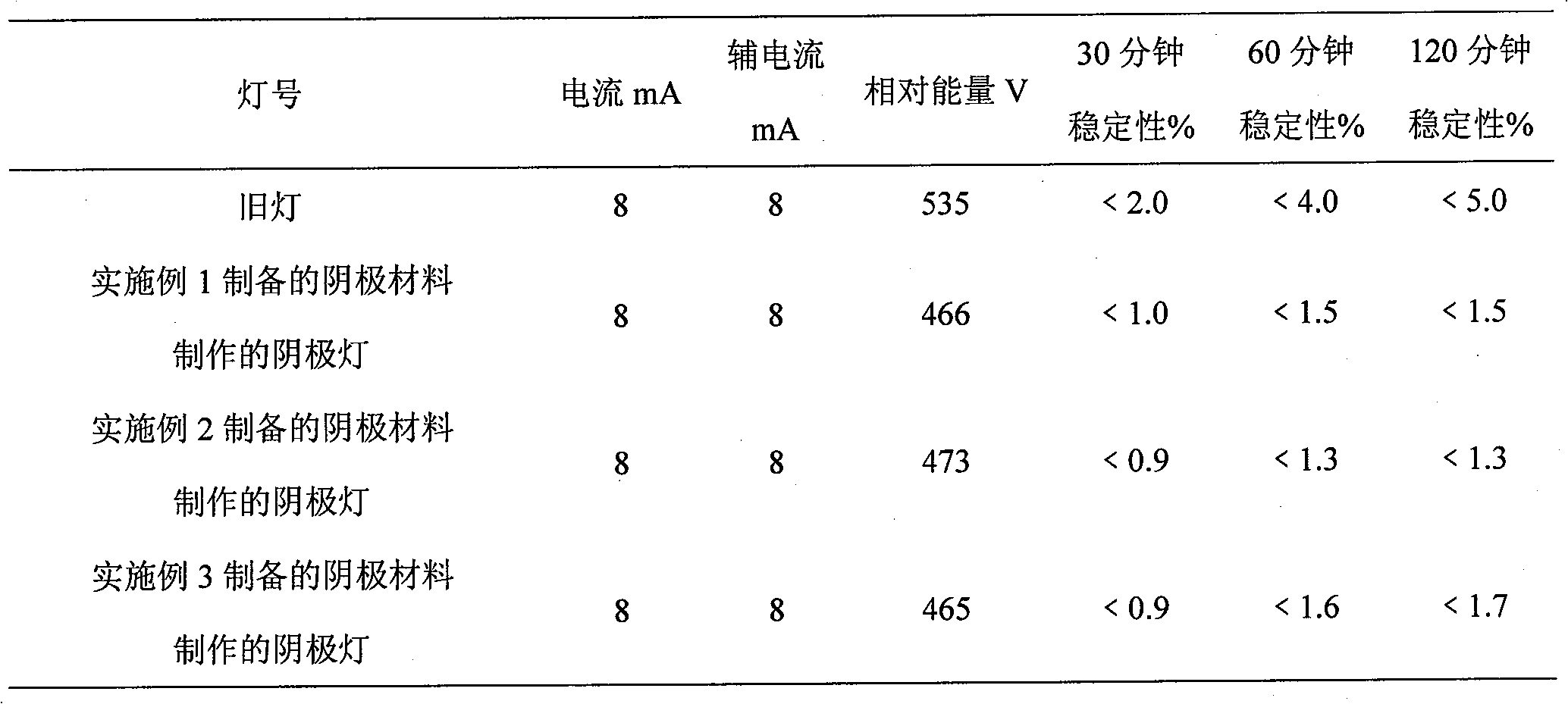

[0023] The hollow cathode lamp that prepared cathode material is made is used in atomic absorption spectrometer G660, test condition slit 0.2nm, wavelength 1960.0nm, with old lamp (c...

Embodiment 2

[0025] A cathode material for a hollow cathode lamp, the cathode material is composed of AgSe alloy, the percentage content of Se in the AgSe alloy is 65%, and the percentage content of Ag is 35%.

[0026] A method for preparing a cathode material of a hollow cathode lamp, the method steps are as follows,

[0027] (1) Take metallic silver and metallic selenium (metallic silver and metallic selenium are powders, and the purity is greater than 99.99%) and mix according to the above ratio;

[0028] (2) Put the mixture into the quartz crucible, put the crucible into the melting equipment, and evacuate until the vacuum degree is less than 10 -3 Pa;

[0029] (3) Heating the mixture to 1200° C., melting the raw materials, stirring, melting for 120 minutes, and cooling with the furnace to obtain the AgSe alloy.

[0030] The hollow cathode lamp that prepared cathode material is made is used in atomic absorption spectrometer G660, test condition slit 0.2nm, wavelength 1960.0nm, with o...

Embodiment 3

[0032] A cathode material for a hollow cathode lamp, the cathode material is composed of AgSe alloy, the percentage content of Se in the AgSe alloy is 70%, and the percentage content of Ag is 30%.

[0033] A method for preparing a cathode material of a hollow cathode lamp, the method steps are as follows,

[0034] (1) Take metallic silver and metallic selenium (metallic silver and metallic selenium are powders, and the purity is greater than 99.99%) according to the above ratio, and mix;

[0035] (2) Put the mixture into the quartz crucible, put the crucible into the melting equipment, and evacuate until the vacuum degree is less than 10 -3 Pa;

[0036] (3) Heating the mixture to 1400° C., melting the raw materials, stirring, melting for 240 minutes, and cooling with the furnace to obtain the AgSe alloy.

[0037] The hollow cathode lamp that prepared cathode material is made is used in atomic absorption spectrometer G660, test condition slit 0.2nm, wavelength 1960.0nm, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com