Method for preparing high polymer material by alpha-angelica lactone ring-opening polymerization

A polymer material, Angelica lactone technology, applied in the field of polymer synthesis, to achieve the effect of high molecular weight, high atom economy, easy to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

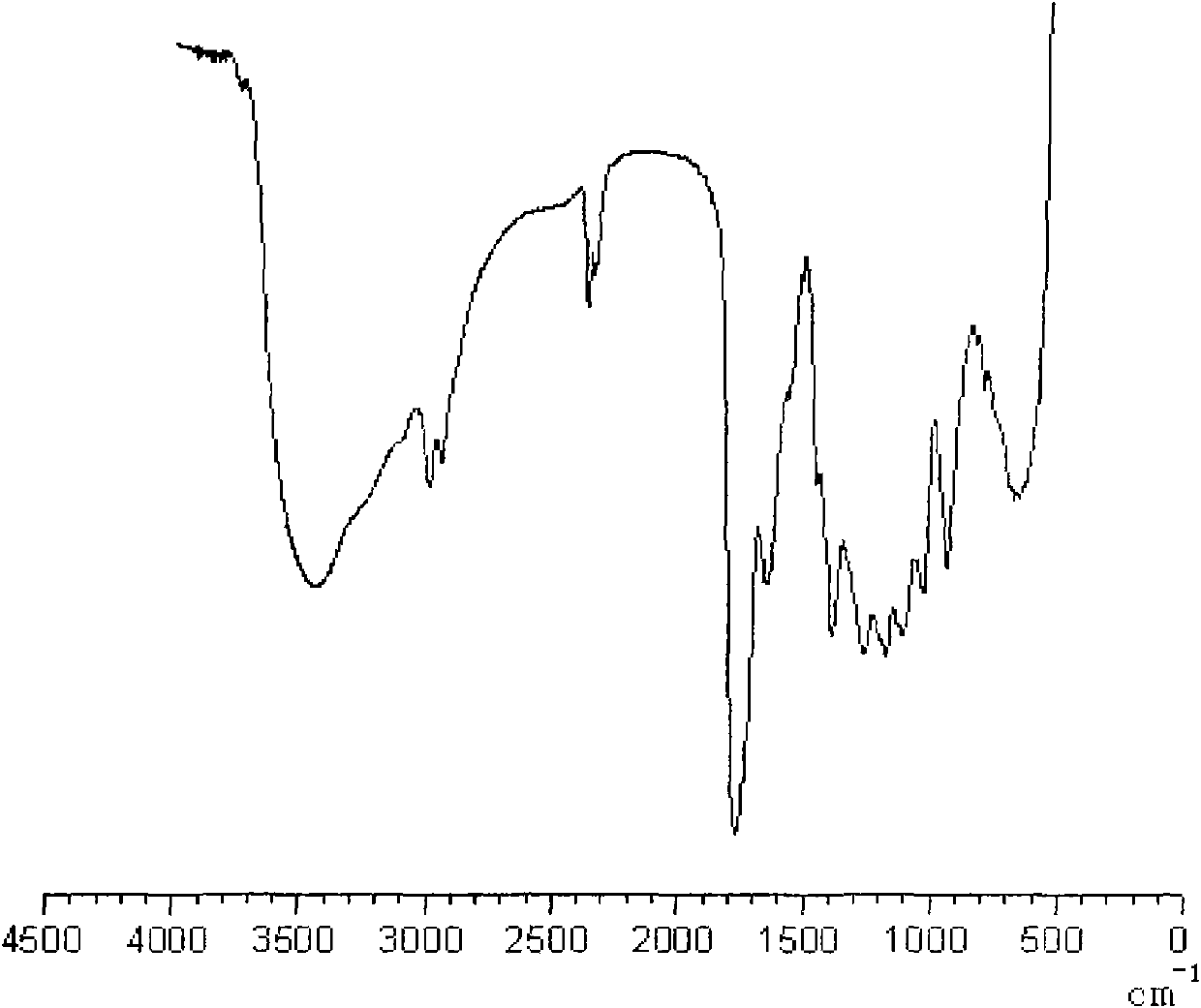

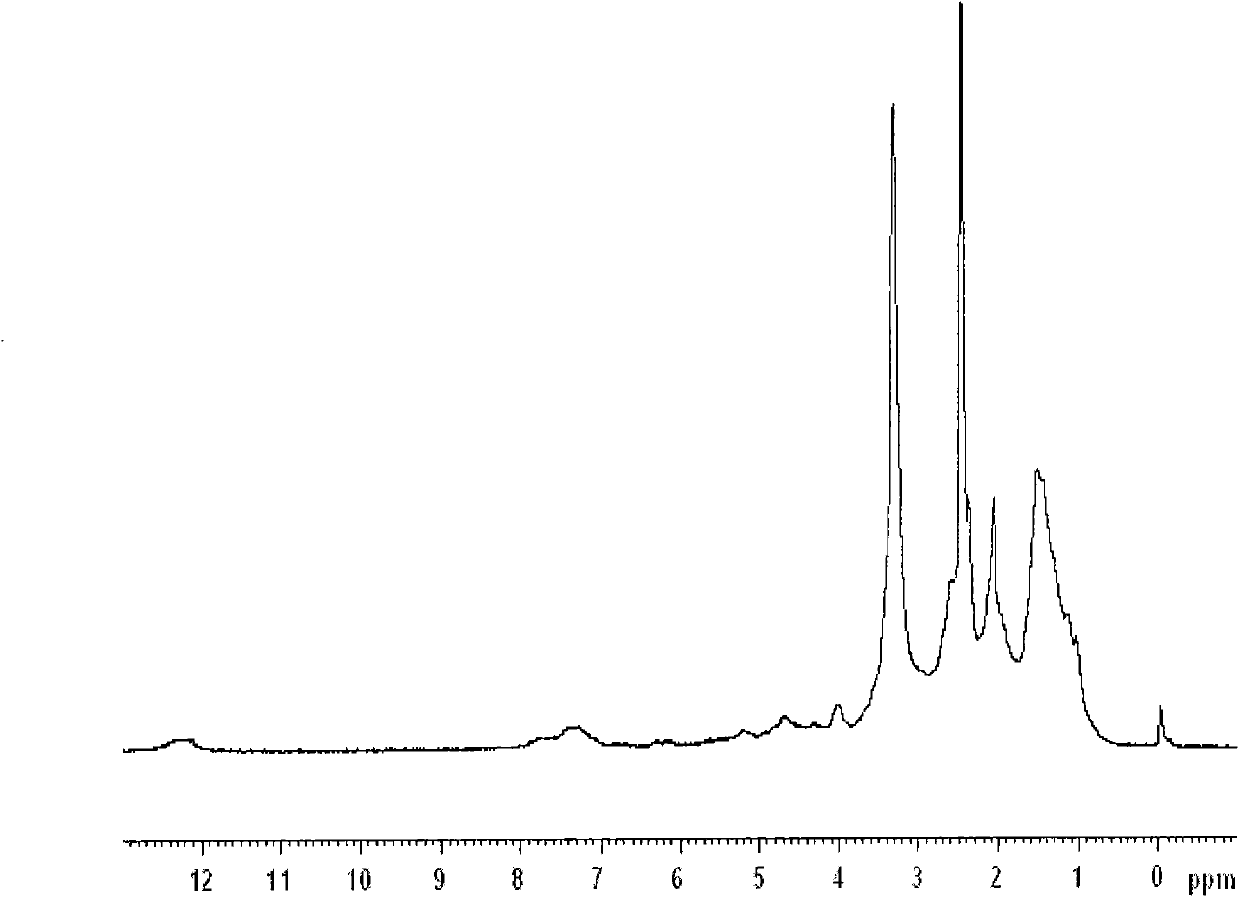

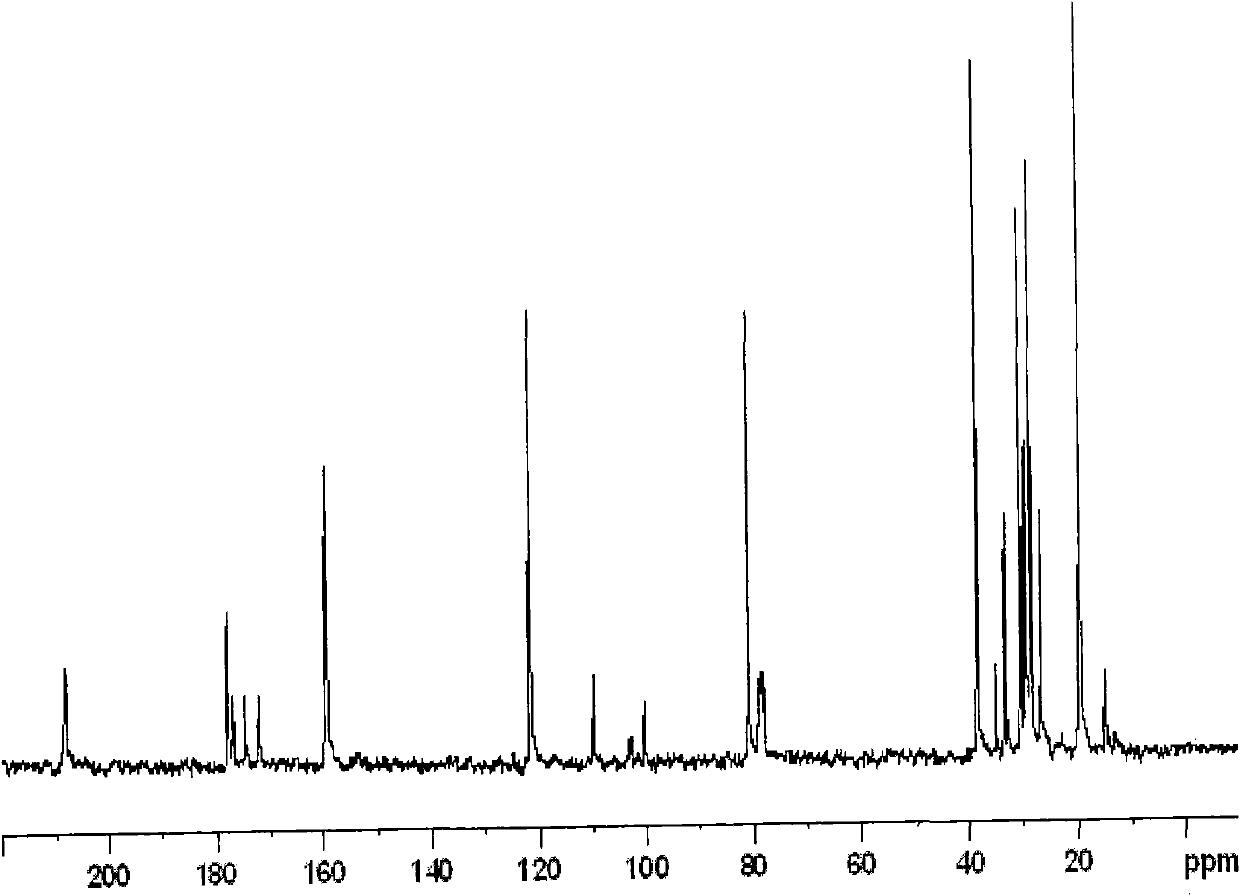

Image

Examples

Embodiment 1

[0028] Under the protection of high-purity nitrogen, add 4.90g of α-angelica lactone and stannous octoate with a molar ratio of 1:10000 to α-angelica lactone to the reaction flask, heat the oil bath to 200°C, take out the reaction for 2h, cool, add 10ml of ethanol, small molecules were dissolved in ethanol, high polymer was precipitated in methanol, filtered and dried to obtain solid poly-angelica lactone. The molecular weight of the polymer measured by gel permeation chromatography was 15.0×10 4 , the molecular weight distribution is 1.26.

Embodiment 2

[0030] Under the protection of high-purity carbon dioxide, add 7.84g of α-angelica lactone and aluminum triisopropoxide with a molar ratio of 1:8000 to α-angelica lactone to the reaction flask, heat the oil bath to 180°C, and take it out after 6 hours of reaction. After cooling, 15ml of methanol was added, the small molecules were dissolved in methanol, and the high polymer was precipitated in petroleum ether, filtered and dried to obtain solid poly-angelica lactone. The molecular weight of the polymer measured by gel permeation chromatography was 14.6×10 4 , the molecular weight distribution is 1.24.

Embodiment 3

[0032] Under the protection of high-purity nitrogen, add 10mL α-angelica lactone (10.84g) and 30mL tetrahydrofuran to the reaction flask, then add tetraphenyltin with a molar ratio of α-angelica lactone of 1:6000, and heat the oil bath to 160°C, react for 10 hours, take it out, cool, add 30ml of ethanol, dissolve the small molecule substance and reaction solvent in ethanol, and precipitate the high polymer in ethanol, filter and dry to obtain solid poly-angelica lactone. The molecular weight of the polymer measured by gel permeation chromatography was 13.9×10 4 , the molecular weight distribution is 1.20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com