Method for preparing high-purity adipic acid dimethyl ester by catalytic gas stripping coupling technology

A technology of dimethyl adipate and adipic acid, which is applied in the field of preparation of dimethyl adipate, can solve the problems of increased production cost, limited acid conversion rate, complicated process, etc., to avoid corrosion and post-processing Effortless, high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

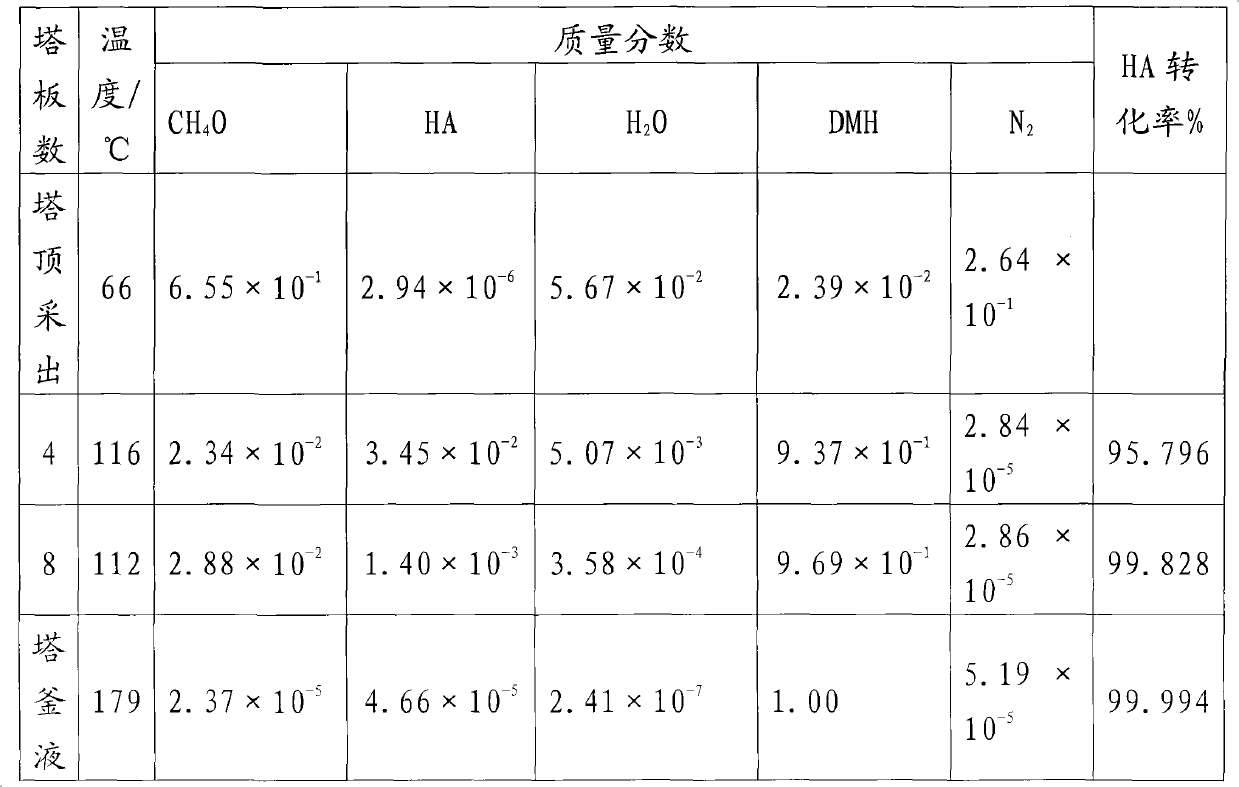

[0042] The stripping tower with a tower diameter of 100mm adopts a plate tower with deflectors, operated at normal pressure, with 15 stages of trays (the condenser and the tower kettle are regarded as the first and 15th stage trays respectively), and the plate spacing is 60mm , The thickness of the liquid layer on the plate is 50mm, and the liquid holding capacity of each stage of the plate is about 200-245ml. There are strong acid ion exchange resin catalysts scattered on the 3-13 stage trays, and the D008 type dimethyl adipate special catalyst is used. The dry weight of the catalyst on each stage tray is about 15% of the liquid mass on each stage tray . The feeding rate of the liquid phase of adipic acid composed of adipic acid and dimethyl adipate is 500mol / h, the molar content of adipic acid is 20%, the feeding temperature is 110°C, and it is fed from the third stage tray. The molar ratio of methanol to adipic acid is 15 times, and it is fed from below the 12-stage tray, ...

Embodiment 2

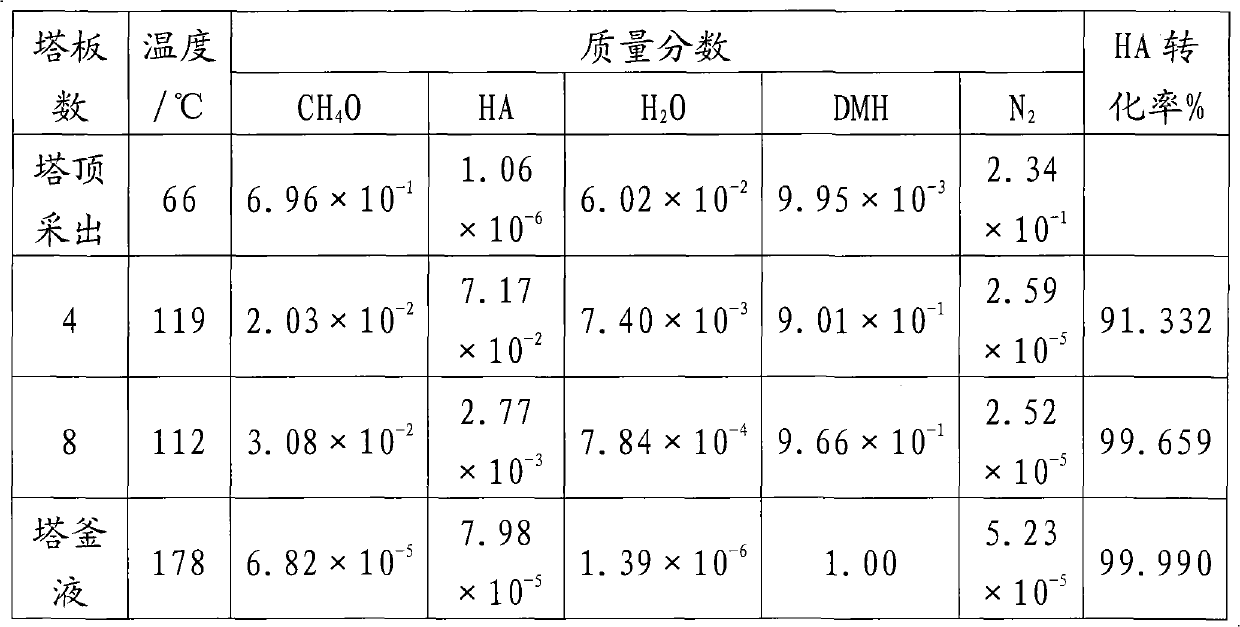

[0049] N with a flow rate of 500mol / h 2 Air stripping is carried out, the reflux ratio at the top of the tower is 0.11, adipic acid is fed into 4 plates, methanol is fed into 12 plates, and catalysts are installed on 4-13 plates. Other experimental conditions are the same as in Example 1. The results are shown in Table 2.

[0050] Table 2 Results of Example 2

[0051]

[0052] The reaction section is reduced, and N is stripped 2 The flow rate decreases, the conversion rate of adipic acid can still reach 99.99%, and the purity of dimethyl adipate obtained in the tower still can reach 99.98%.

Embodiment 3

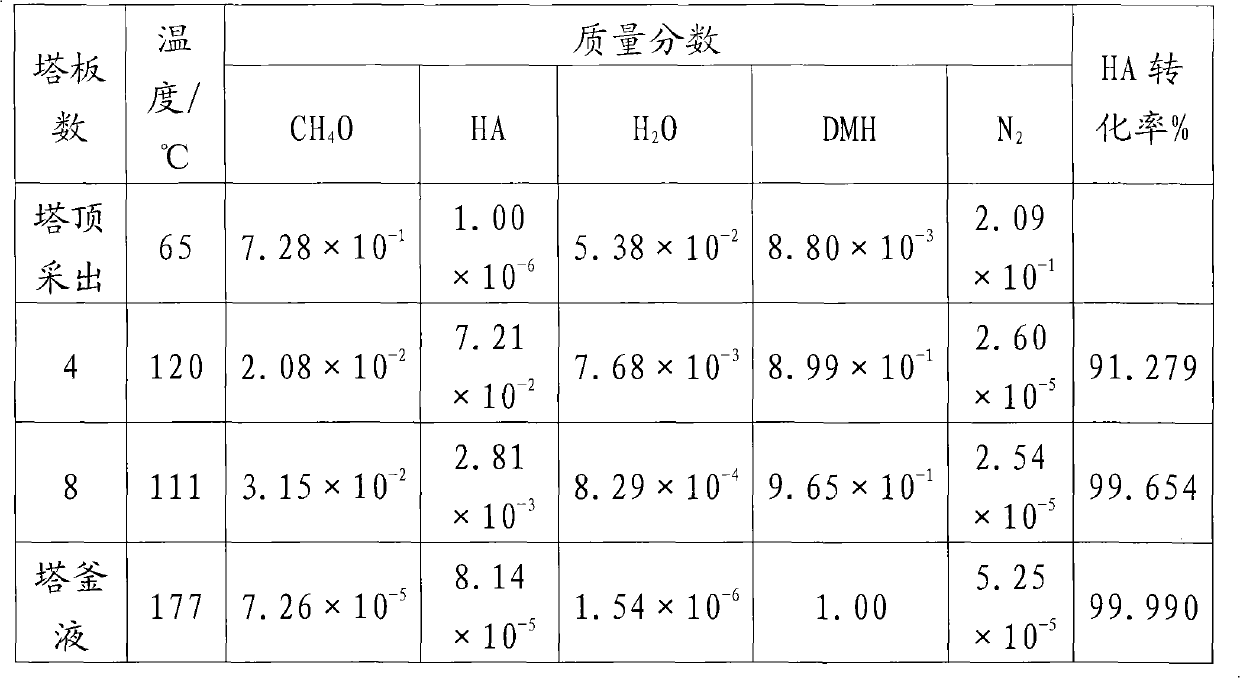

[0054] The top of the tower is refluxed with pure methanol at 20°C, 220mol / h. Other experimental conditions are identical with example 2. The results are shown in Table 3.

[0055] Table 3 Results of Example 3

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com