Coupling treatment device and coupling treatment method for sweet sorghum fuel ethanol wastewater circumfluence bioreactor

A fuel ethanol wastewater and bioreactor technology, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low crude protein content, difficult to handle waste residue, suspended solids content High-level problems, to achieve the effect of high treatment efficiency, short start-up time and high sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

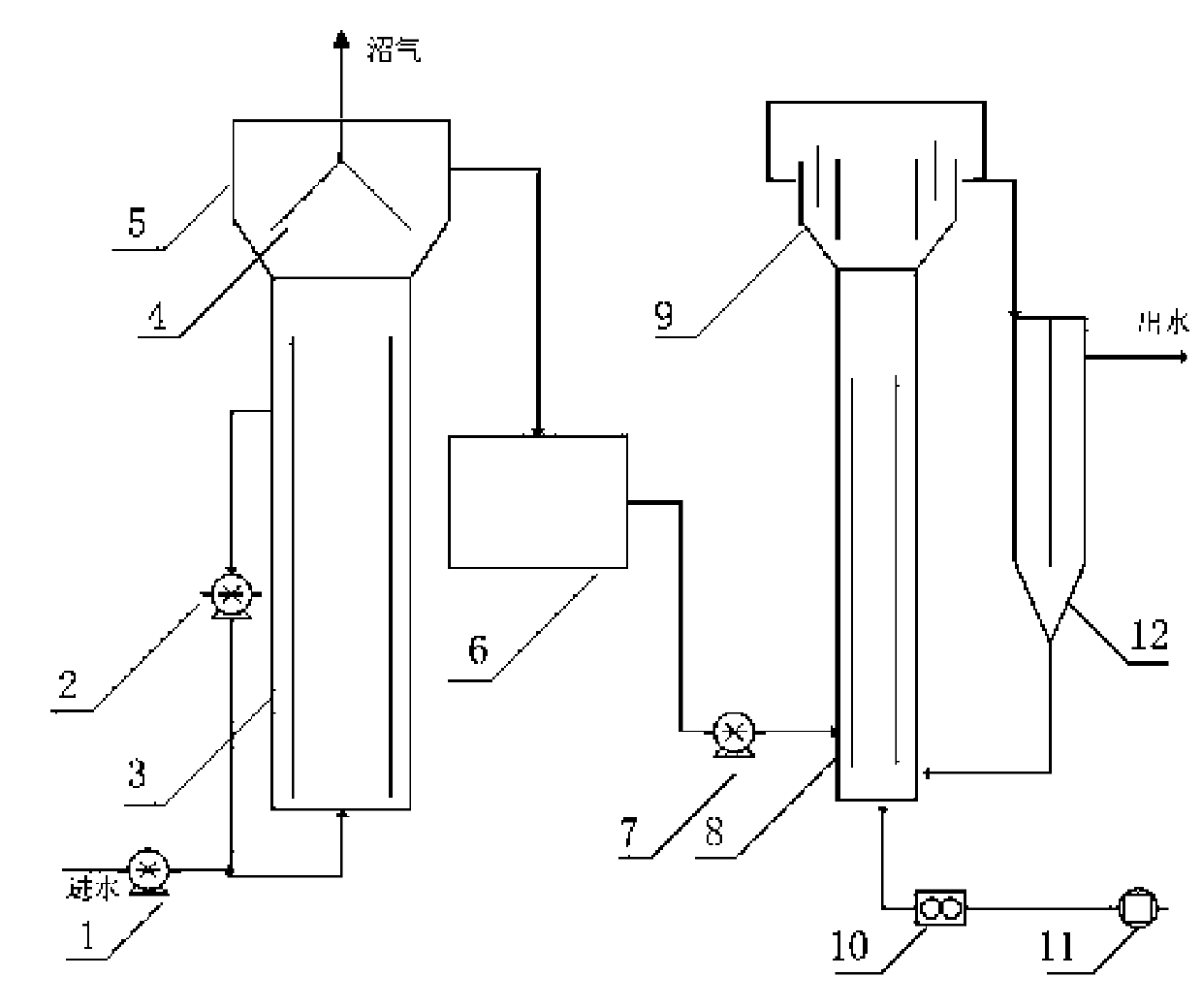

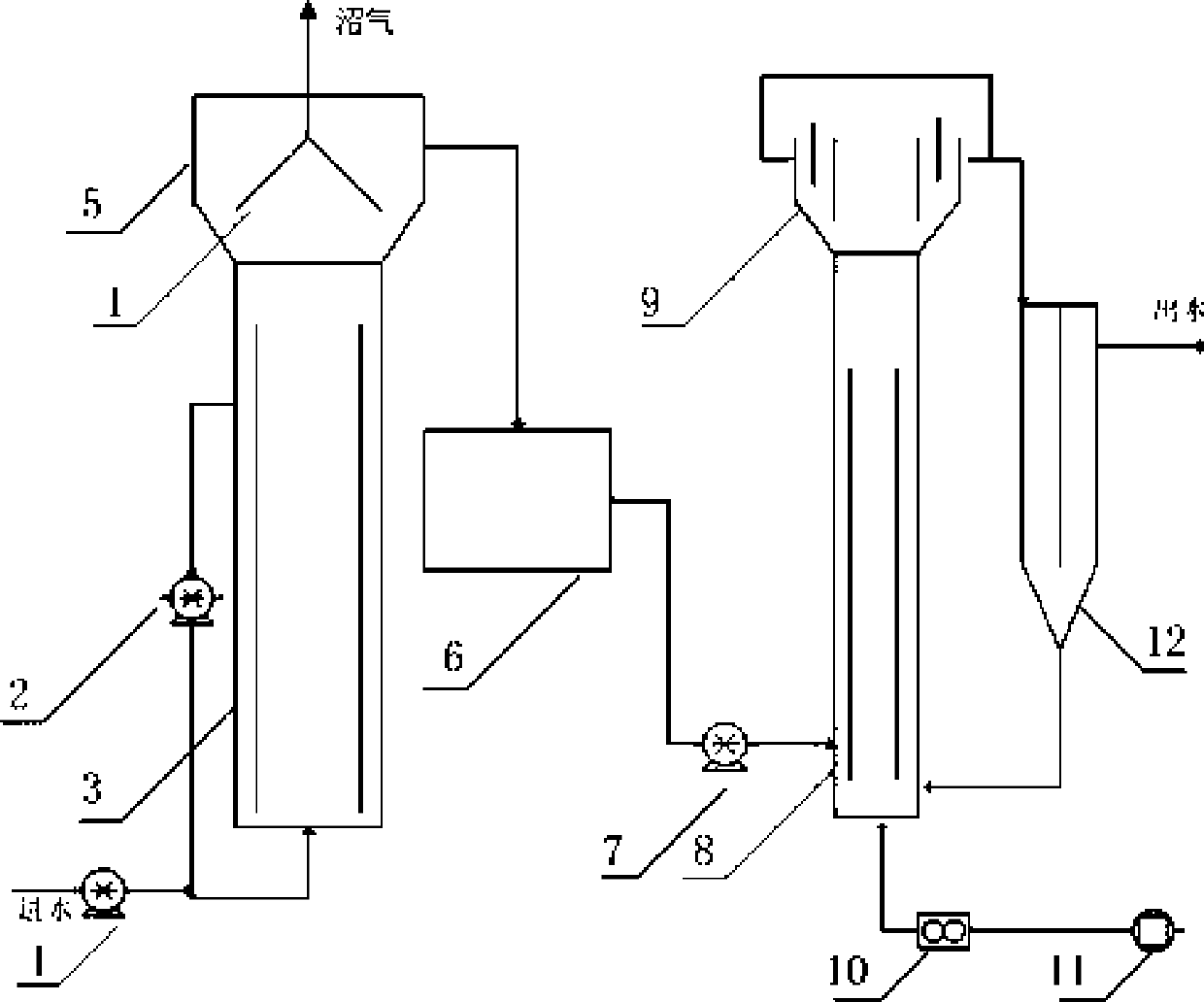

Embodiment 1

[0027] 30% normal temperature anaerobic activated sludge is connected to the anaerobic reactor, the effective volume of the anaerobic reactor is 10L, the diameter of the outer shell is 120mm, the height is 900mm, the diameter of the diversion tube is 80mm, the height is 800mm, the diameter of the settlement zone is 200mm, and the height is 100mm. The reactor temperature is 3335°C, the sweet sorghum fuel ethanol wastewater is diluted 5 times intermittently for 3 days, the water is fed continuously, the hydraulic retention time is 96h, the reflux rate is 35L / h, the COD removal rate of the effluent is higher than 75%, the concentration of the influent water is increased, and the gradient domestication is rich Collect activated sludge, after 18 days of gradient acclimatization, the raw water is directly fed into the water, the temperature of the reactor is raised to 55°C at 1°C / d, the temperature range is controlled at 53-55°C, and the COD removal rate of the anaerobic effluent reac...

Embodiment 2

[0030] The effective volume of the anaerobic internal circulation bioreactor is 5L, the diameter of the outer shell is 95mm, the height is 720mm, the diameter of the guide tube is 60mm, the height is 500mm, the diameter of the settlement zone is 160mm, and the height is 60mm; the effective volume of the aerobic circulation bioreactor is 1L, and the outer shell The diameter is 55mm, the height is 500mm, the diameter of the guide tube is 30mm, and the height is 390mm; the volume of the settler is 0.5L; start the coupling device according to the method in Example 1.

[0031] Sweet sorghum fuel ethanol wastewater COD24500-25000mg / L, SS10500-11000mg / L, pH4.5, directly into the coupling device for treatment without pretreatment, anaerobic internal circulation bioreactor operating temperature 53-55 ℃, reflux pump flow 21- 23L / h, the hydraulic retention time is 72 hours; the operating temperature of the aerobic circulation bioreactor is 33-35°C, and the air velocity is 0.035-0.040m 3 ...

Embodiment 3

[0033] The effective volume of the anaerobic internal circulation bioreactor is 3L, the diameter of the outer shell is 92mm, the height is 460mm, the diameter of the guide tube is 60mm, the height is 400mm, the diameter of the settlement zone is 160mm, and the height is 50mm; the effective volume of the aerobic circulation bioreactor is 1L, and the outer shell The diameter is 55mm, the height is 500mm, the diameter of the guide tube is 30mm, and the height is 390mm; the volume of the settler is 0.5L; start the coupling device according to the method in Example 1.

[0034] Sweet sorghum fuel ethanol wastewater COD15500-16000mg / L, SS7500-8000mg / L, pH3.5, without pretreatment, directly enters the coupling device for treatment, the operating temperature of the anaerobic internal circulation bioreactor is 53-55℃, and the flow rate of the reflux pump is 20- 22L / h, the hydraulic retention time is 36 hours; the operating temperature of the aerobic circulation bioreactor is 33-35°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com