Infrared ray welding device for welding bar-shaped zone

A welding device, infrared technology, applied in welding equipment, electrical components, climate sustainability, etc., can solve the problems of reduced production efficiency, inability to weld a group of components, limited irradiation range, etc., to improve the quality of finished products and ensure the welding surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

[0041] The invention discloses an infrared welding device for welding a strip-shaped area, which comprises a plurality of welding unit mechanisms 1, and each welding unit mechanism 1 is connected to each other through a connecting mechanism 2, and the distance between them can be adjusted through the connecting mechanism 2. Make adjustments.

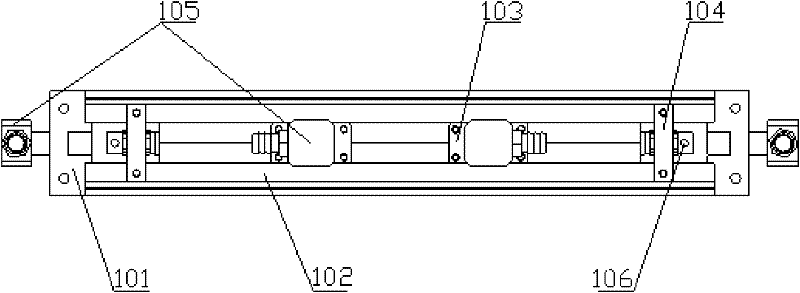

[0042] Such as Figure 1 to Figure 4 As shown, the welding unit mechanism 1 is mainly composed of an infrared lamp 106 , a lamp installation frame 104 , a reflector 102 , a lampshade fixing plate 101 , an air blowing joint 105 and an air blowing joint fixing plate 103 .

[0043] The longitudinal section of the inner cavity of the reflector 102 is semi-elliptical, that is, a part of the ellipse, forming a semi-elliptical cylindrical cavity as a whole, and the semi-elliptical cylindrical cavity forms two focal line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com