Drill stem thickening process and thickening module

A technology for upsetting and drilling rods, which is used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can solve the problems of short service life, stress concentration, and sudden changes in size of drill rods, and ensure the quality of drill rods. The effect of reducing stress concentration and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

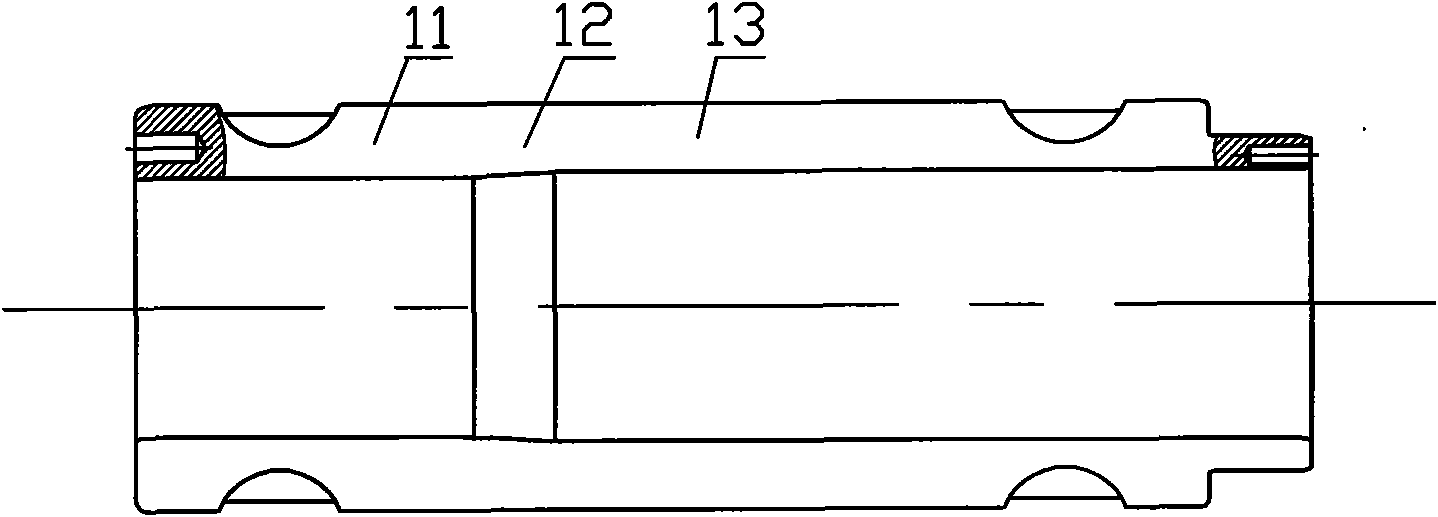

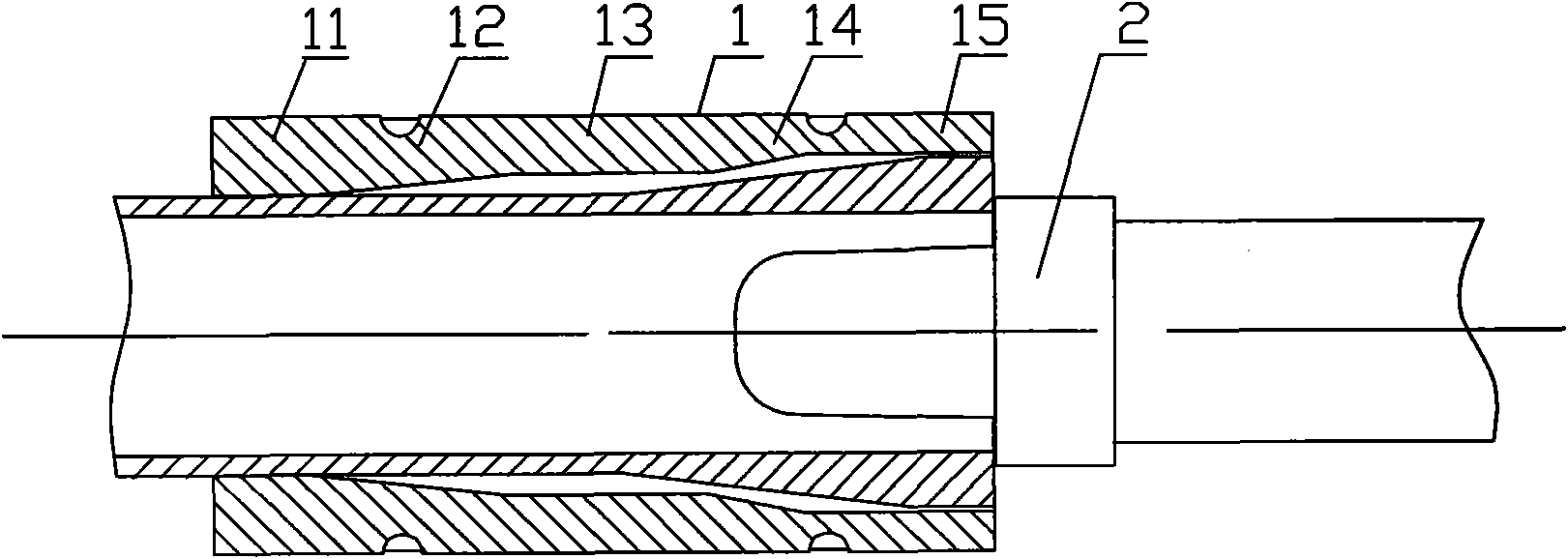

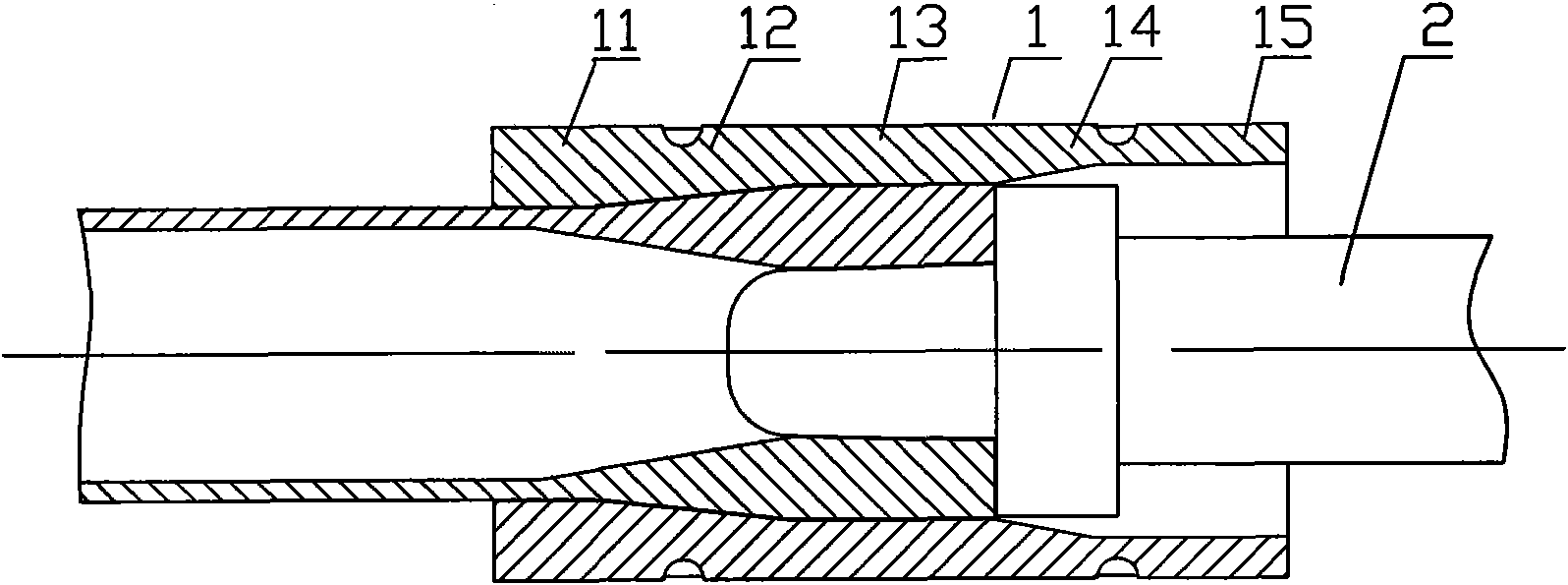

[0013] A drill pipe upsetting and thickening process and a thickening mold. After heating the pipe end of the drill pipe with an intermediate frequency heating furnace, the pipe end is thickened three times by a thickening machine, and only the first and second thickening are performed. External thickening - upsetting forming, and greatly extending the length of the transition zone of the thickening die, and adopting an S-shaped smooth transition. The outer diameter of the upsetting part of the drill pipe after the second thickening is larger than the outer diameter of the finished product size. The principle The cross-sectional area of the second thickening end is equal to the cross-sectional area of the finished product at the corresponding position; only the inner thickening is carried out in the third thickening—copy molding, and the shape of the outer thickening is copied to the inner surface of the thickening end by extrusion , that is, the shape and size of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com