Back film for solar module

A solar cell and back film technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of solar cell module leakage, low production efficiency, short circuit of metal foil, etc., and achieve good water vapor barrier performance, good cost, and cost control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

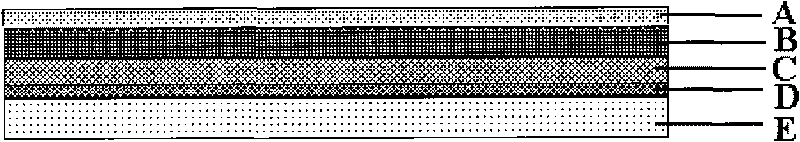

Embodiment 1

[0031] In the back film manufacturing process, first PET, EVOH and PA610 are stretched by three layers of co-extrusion in a mass ratio of 100:30:10 to obtain a 300-micron-thick middle layer, and the ethylene content in the selected EVOH is 38%; then, in Composite 30-micron thick PVDF film on the PET surface, and coat a 350-micron thick EVA film on the PA610 surface. The ingredients of the EVA film are 33% ethylene-vinyl acetate copolymer (U.S. DuPont) with a VA (vinyl acetate) mass content. 59%, opacifying filler titanium dioxide R906 (U.S. DuPont Company) 40%, add 0.1% ultraviolet absorber 2,2'-tetramethylene bis(3,1-benzoxazin-4-ketone) (Nanjing Zhong He Sheng Technology Co., Ltd.), 0.1% light stabilizer N, N'-bis(1,2,2,6,6-pentamethyl-4-piperidinyl)-1,6-hexamethylenediamine and morpholine -polymer of 2,4,6-trichloro-1,3,5-triazine (Beijing Tiangang Co., Ltd.), 0.2% antioxidant 1,3,5-tris(4-tert-butyl-3 -Hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione / bis...

Embodiment 2

[0033] In the back film manufacturing process, first PEN, EVOH and EVA are stretched by three layers of co-extrusion in a mass ratio of 100:30:10 to obtain a 250-micron-thick middle layer. The ethylene content in the selected EVOH is 38%, and the selected EVA does not contain additive, only as bonding layer; Then, compound the thick PVF film of 30 microns on PET surface, flow coat the EVA film of 400 microns thick on bonding layer surface, VA (vinyl acetate) mass content in this EVA batching is 33% ethylene-vinyl acetate copolymer (U.S. DuPont) 75%, the shading filler is 20% of carbon black N550 (Germany Degussa), and 0.5% of UV absorber 2-(2'-hydroxyl- 5-methylphenyl)benzotriazole (Nanjing Zhonghesheng Technology Co., Ltd.), 0.5% antioxidant 1,3,5-tri(4-tert-butyl-3-hydroxyl-2,6-di Methylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione / bis(2,4-dicumylphenyl)pentaerythritol diphosphite Compound (mass ratio 1:1; American Cytec Corporation), 2.5% light stabilizer succinic acid an...

Embodiment 3

[0035] In the back film manufacturing process, first PET, EVOH and PA612 are stretched by three layers of co-extrusion in a mass ratio of 100:70:10 to obtain a 50-micron-thick middle layer, and the ethylene content in the selected EVOH is 44%; then, in The PET surface is compounded with a 30-micron thick ETFE film, and a 100-micron thick EVA film is flow-coated on the PA612 surface. The EVA ingredients are the same as in Example 1, so that it has light-shielding properties, encapsulation and weather resistance. The resulting sample is labeled S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com