Method for rapidly detecting pipeline body defects

A detection method and pipeline detection technology, which are applied in the field of ultrasonic measurement and pipeline system, can solve the problems of incapability of mature and reliable application of oil and gas pipeline detection methods, and achieve the effect of shortening the detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

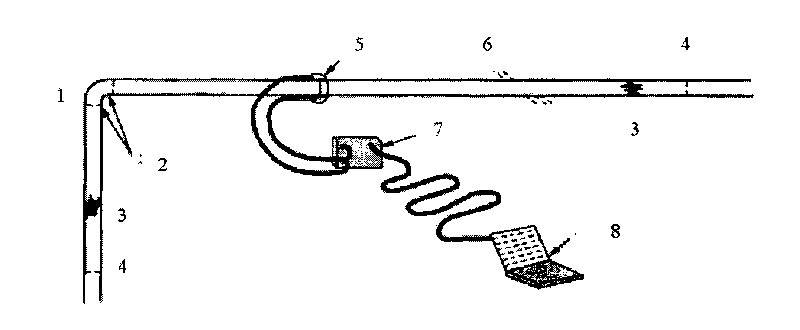

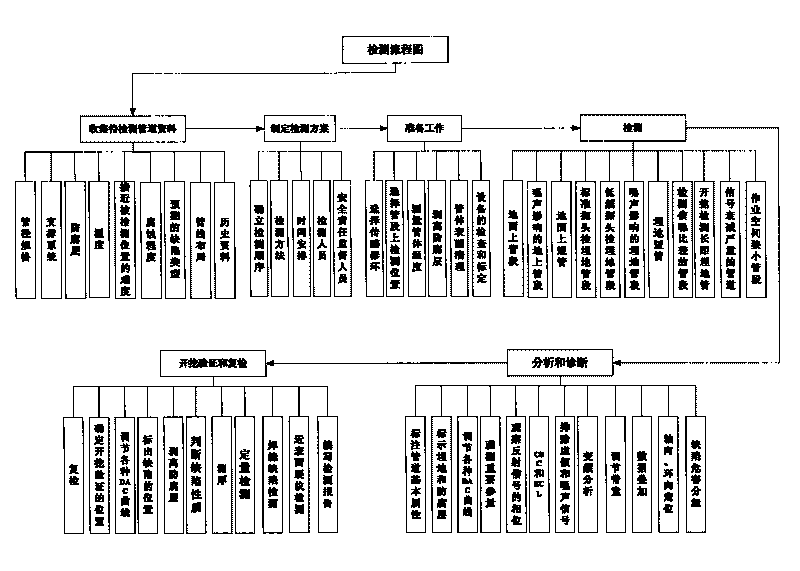

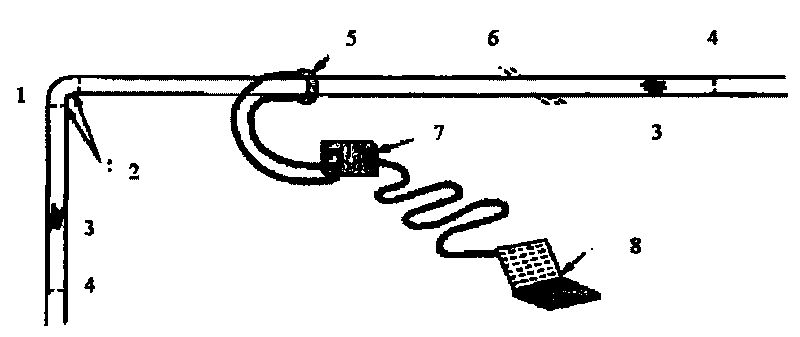

[0117] Embodiment. This example is the method that carries out test at Baodi Station, and its composition is as figure 1 As shown, the process is as follows figure 2 shown. figure 1 A schematic diagram of the detection of common elbow sections is given in , in the figure 1-bend, 2-welds on both sides of the elbow, 3-corrosion, 4-girth weld, 5-sensor ring, 6-pipe support, 7 - Detect Host, 8 - Computer.

[0118] The detection process in this example is as follows:

[0119] 1) Understand and master the pipeline specification, pipeline support system, pipeline anti-corrosion layer, pipe body temperature, difficulty of approaching the detected position, corrosion degree, expected defect type, pipeline layout and historical situation information of the oil and gas pipeline to be tested;

[0120] 2) Complete the preparatory work of selecting the sensor ring, measuring the temperature of the pipe body, cleaning the surface of the oil and gas pipeline to be tested, and checking and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com