Evaporator and loop type heat pipe applying same

An evaporator and loop technology, applied in the field of loop heat pipes, can solve problems such as reducing the effective pressure difference of loop heat pipes, failure of loop heat pipes, and drying of working fluid, so as to prevent dryness, prolong service life, and ensure permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

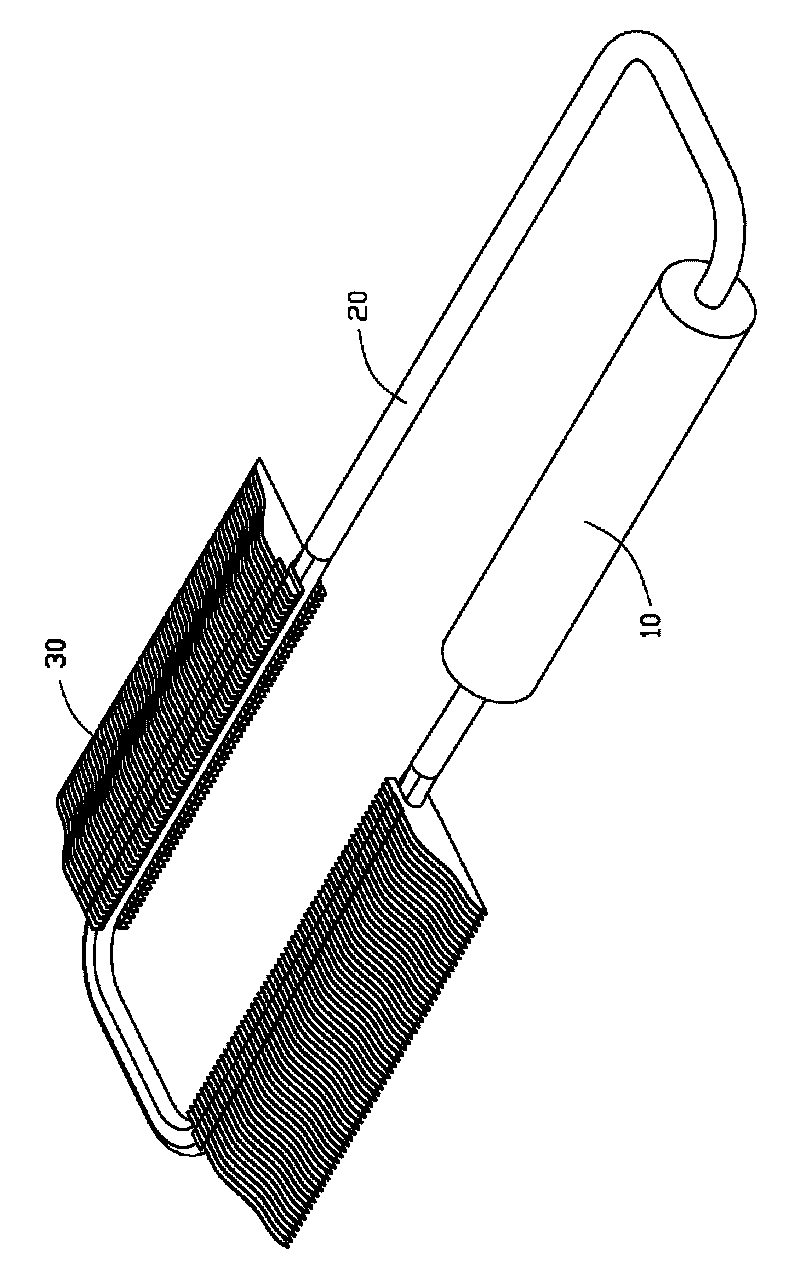

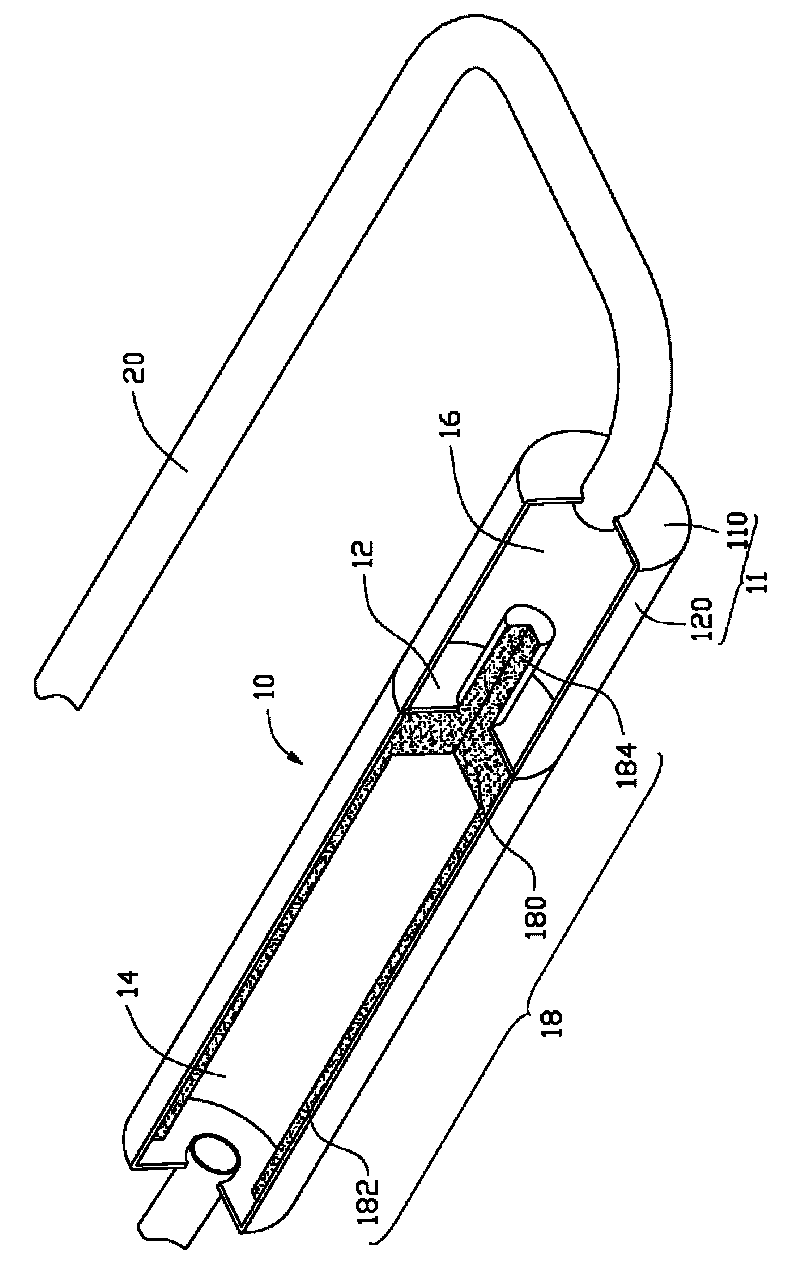

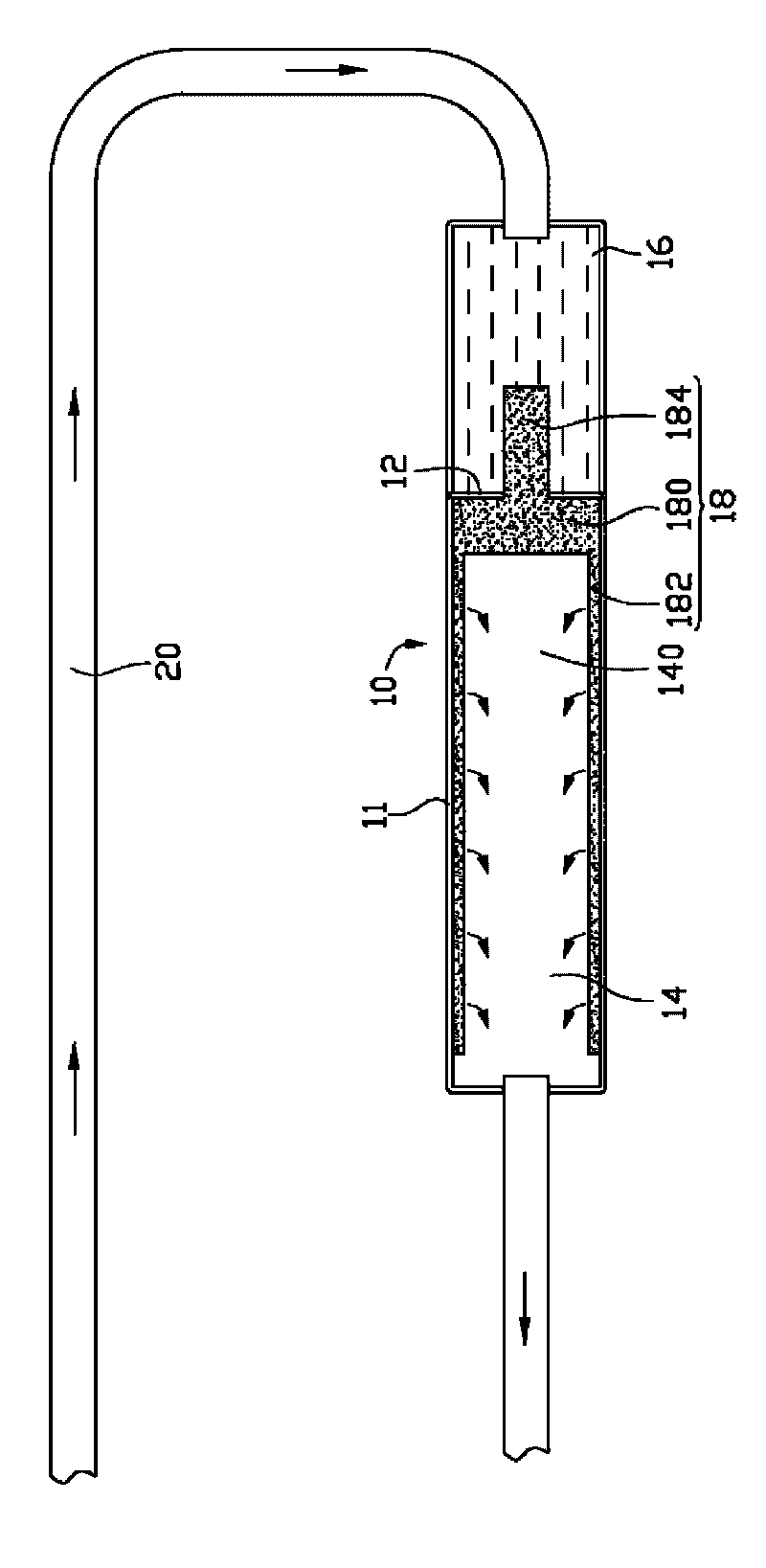

[0012] see figure 1 A loop heat pipe according to a preferred embodiment of the present invention includes an evaporator 10 , pipes 20 connecting opposite ends of the evaporator 10 , and a plurality of cooling fins 30 sleeved on the pipes 20 . The pipeline 20 connects opposite ends of the evaporator 10, so that the evaporator 10 and the pipeline 20 form a sealed circuit. The circuit is filled with working liquid (such as image 3 shown), the working liquid can be water, alcohol, etc. The pipeline 20 can be made of flexible materials compatible with the working fluid, such as copper, aluminum or stainless steel. One end of the evaporator 10 absorbs the heat generated by a heat-generating electronic component such as a CPU, and evaporates the working liquid. The vapor flows out along the pipeline 20 and is cooled by the cooling fins 30 to cool the vapor into a liquid. The liquid flows into the pipeline 20 and evaporates. The other end of the device 10, so that the loop heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com