Solvent type aeolotropic nano conductive adhesive and manufacturing method thereof

An anisotropic, nano-conductive technology, applied in the direction of adhesive types, conductive adhesives, adhesives, etc., can solve the problems of complex reaction conditions, long reaction time, low yield, etc., and achieve simple preparation, uniform particles, loading The effect of stream improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] 2. Preparation of anisotropic conductive adhesive:

[0045] The above-mentioned high-concentration conductive particle solution is mixed with a polymer material and a solvent. Among them, the polymer material is polyester, polyurethane, epoxy resin, etc.; the solvent is a polar solvent compatible with ethylene glycol, including water, ethanol, acetone, and dimethylformamide (DMF); the mass ratio of each substance It is: 0.5-5% of conductive particles, 15-45% of polymer materials, and 50-80% of solvents.

[0046] The anisotropic conductive adhesive of the present invention is a solvent type, which is a mixture of conductive fillers and insulating adhesive polymers, and does not form anisotropic conduction before the process is implemented. It can be used in various ways, such as printing method (printing), dispensing method or coating step method.

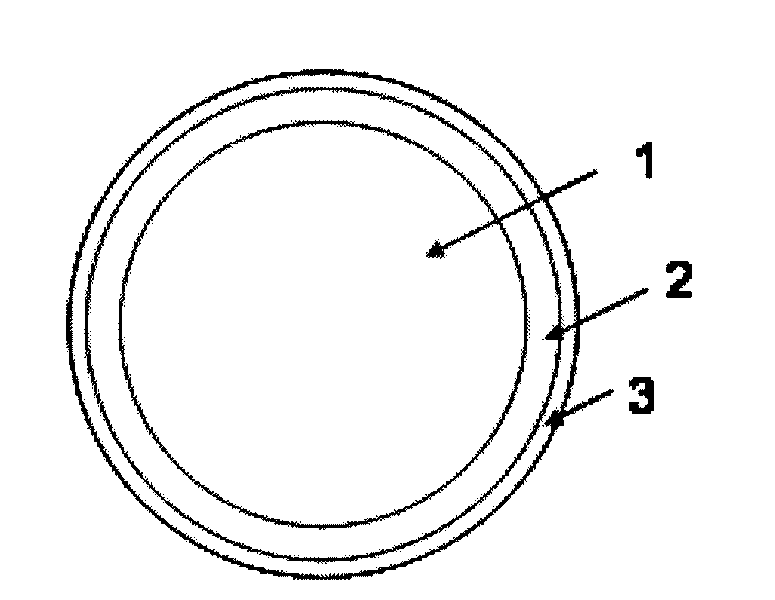

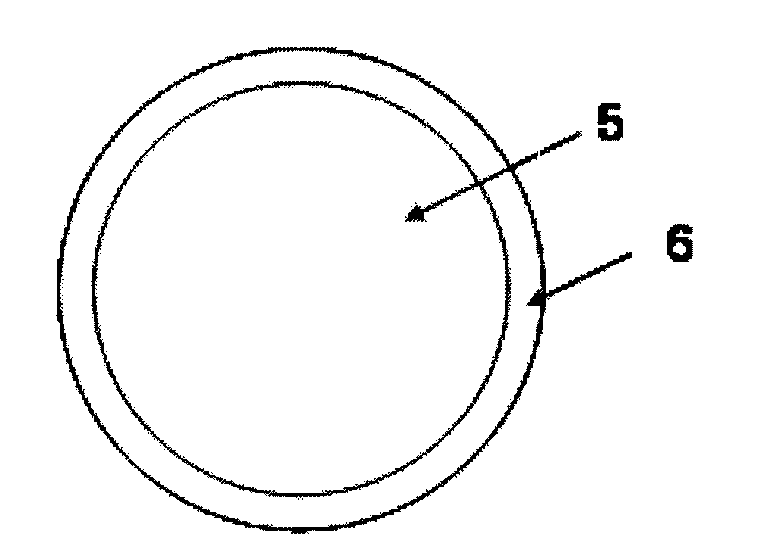

[0047] Compared with traditional composite conductive particles, such as nickel-plated gold or silver-coated particles (s...

Embodiment 1

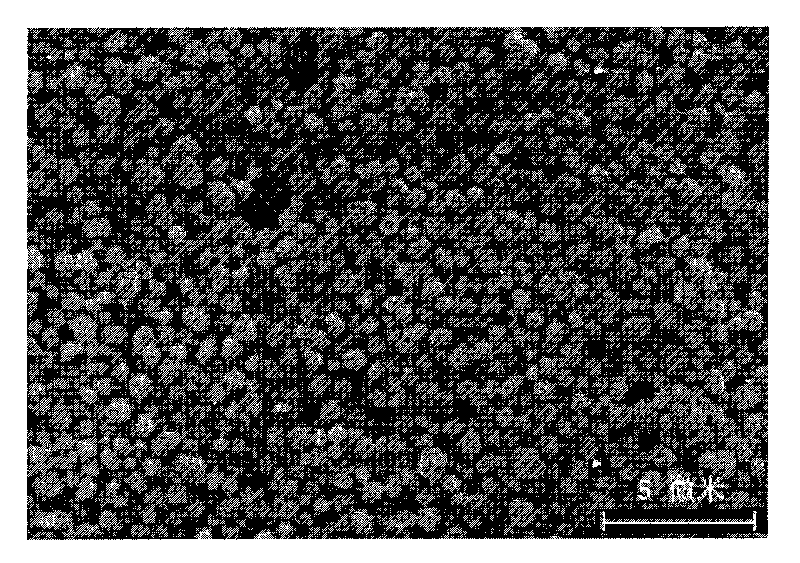

[0069] 1 kg of silver nitrate (AgNO 3 ), 1L ethylene glycol solution and 0.2kg of polyvinylpyrrolidone (PVP) are mixed evenly and then poured into the mixing kettle, and then 20g of sodium chloride solution is poured into the above-mentioned mixed solution and stirred, and after uniform mixing, the solution is placed in an industrial Heating in a microwave oven under 800W power for 10 minutes, a reaction takes place to obtain a dispersion of silver conductive particles (600 nm) with a uniform particle size, and the concentration is 27%. 10 grams of the above dispersion liquid and 100 grams of polyurethane solution Solucote 334 (35% in DMF) were uniformly mixed at a mass ratio of 1:10 to obtain an anisotropic conductive adhesive. Here, the mass ratio of the substances in the conductive adhesive is: 2.5% for conductive particles, 31.8% for polymer materials, and 65.7% for solvents.

Embodiment 2

[0071] 1.5kg silver nitrate (AgNO 3 ), 3L ethylene glycol solution and 2kg of polyvinylpyrrolidone (PVP) are mixed evenly and then poured into the mixing kettle, and then 100g of sodium chloride solution is poured into the above mixture and stirred, and after uniform mixing, the solution is placed in an industrial microwave oven Internally heated at 1200W for 13 minutes, a reaction occurred to obtain a dispersion of silver conductive particles (200 nm) with a uniform particle size, and the concentration was 14%. The dispersion liquid was uniformly mixed with a 35% epoxy resin solution Eponol 53-BH-35 at a mass ratio of 1:8 to obtain an anisotropic conductive adhesive. Here, the mass ratio of each material of the conductive adhesive is: 1.6% of conductive particles, 33.3% of polymer materials, and 65.1% of solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com