Colored translucent printing ink

A colored ink, translucent technology, applied in the direction of ink, household appliances, application, etc., can solve the problems of single product color, affect the appearance of the product, can not achieve the hidden effect, etc., and achieve the effect of good light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

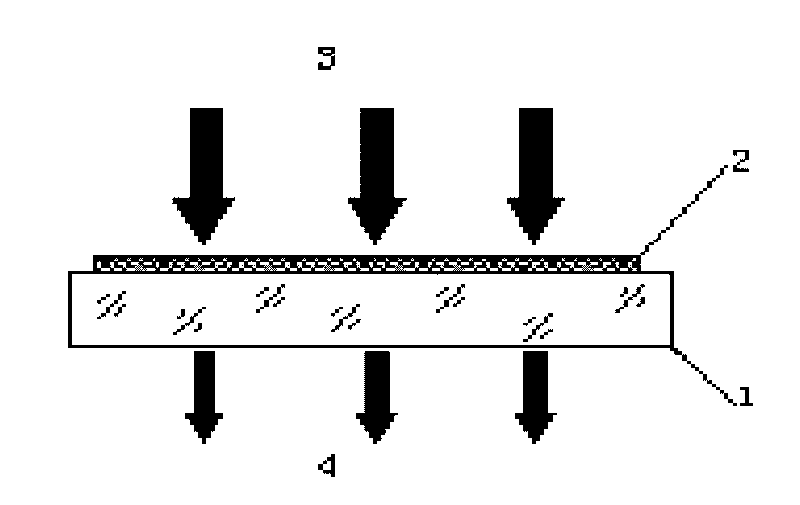

Image

Examples

Embodiment 1

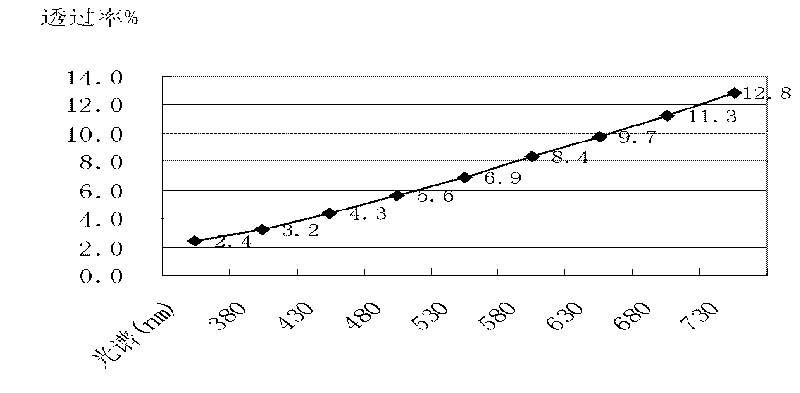

[0029] Colored ink: Varnish: Curing agent: Thinner = 50:15:28:10,

[0030] Colored inks, varnishes, curing agents, and thinners are all purchased by Shenzhen Rizhengtian Technology Co., Ltd.

[0031] Visible light transmittance see figure 2 .

[0032]

[0033]

Embodiment 2

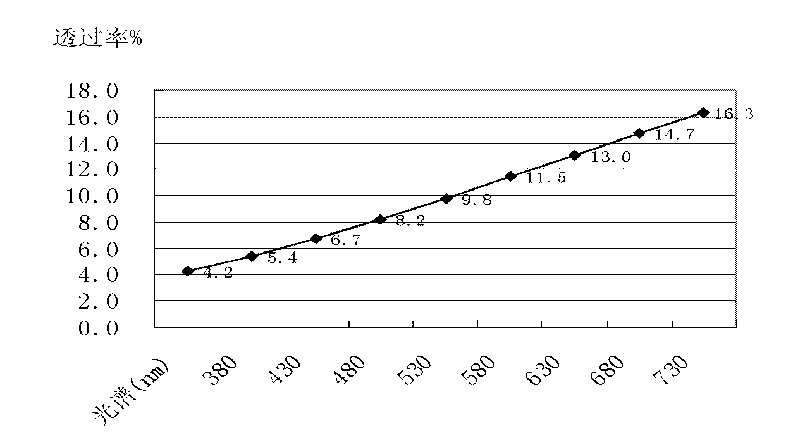

[0035] Colored ink: Varnish: Curing agent: Thinner=50:20:30:12. Visible light transmittance see image 3 .

[0036] Spectrum (nm)

Embodiment 3

[0038] Colored ink: varnish: curing agent: thinner=50:25:32:14. Visible light transmittance see Figure 4 .

[0039] Transmittance data

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com