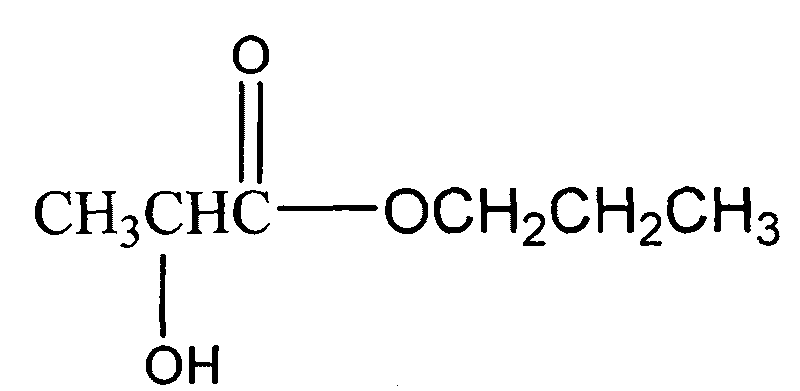

Method for preparing lactic acid n-propyl ester with low water content, low acidity and high purity

A technology with low water content and low acidity, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low water content, low yield of n-propyl lactate, free acid and water content advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

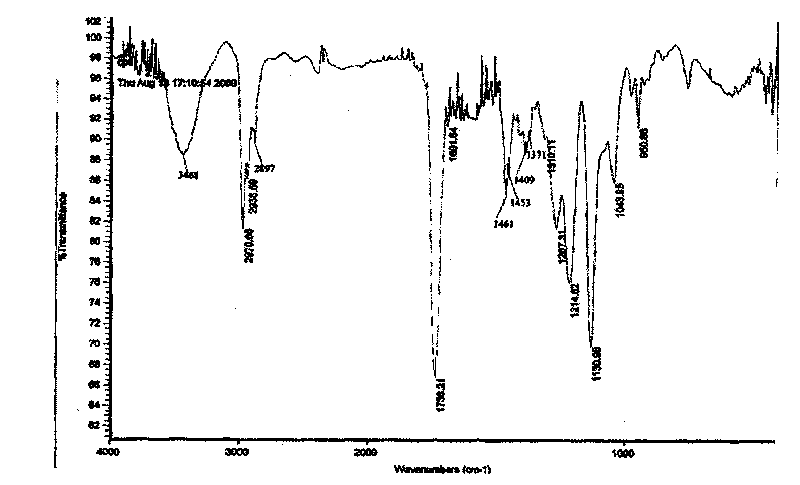

Image

Examples

Embodiment 1

[0018] Lactic acid, n-propanol, water-carrying agent and esterification catalyst are added in the reactor according to the mass ratio of 90:30:90:5, heated and refluxed for 24 hours under stirring; the water-carrying agent-water azeotrope formed during the reaction process After the dehydration of the inorganic mixture formed by compounding calcium oxide, anhydrous magnesium sulfate, anhydrous sodium sulfate and anhydrous zinc sulfate in a mass ratio of 0.001:8:0.005:3, it enters the reactor through a reflux device; after the reaction The material is treated with a mixed organic amine composed of ethylamine, diethylamine, triethylamine, propylamine, dipropylamine, and tripropylamine in a mass ratio of 0.001: 0.005: 6: 0.0007: 0.010: 3, and the pH value of the reaction material is adjusted 7.0, and after stirring for 0.5 hour, adding reaction mass percentage again is anhydrous magnesium sulfate and / or anhydrous sodium sulfate drying of 3% amount; After the material after drying ...

Embodiment 2

[0020] Lactic acid, n-propanol, water-carrying agent and esterification catalyst are added in the reactor according to the mass ratio of 90:90:145:15, and heated to reflux under stirring for 18 hours; the water-carrying agent-water azeotrope formed during the reaction process After the dehydration of the inorganic mixture formed by compounding calcium oxide, anhydrous magnesium sulfate, anhydrous sodium sulfate and anhydrous zinc sulfate in a mass ratio of 8:0.01:1:0.001, it enters the reactor through a reflux device; after the reaction The material is treated with a mixed organic amine composed of ethylamine, diethylamine, triethylamine, propylamine, dipropylamine, and tripropylamine in a mass ratio of 0.5:0.8:3:0.07:3:3, and the pH value of the reaction material is adjusted 6.5, and after stirring for 8 hours, adding reaction mass percentage is anhydrous magnesium sulfate and / or anhydrous sodium sulfate drying of 10% amount; after the material after drying is filtered or cent...

Embodiment 3

[0022]Lactic acid, n-propanol, water-carrying agent and esterification catalyst are added into the reactor in a mass ratio of 90:120:180:0.1, and heated to reflux under stirring for 12 hours; the water-carrying agent-water azeotrope formed during the reaction process After the dehydration of the inorganic mixture formed by compounding calcium oxide, anhydrous magnesium sulfate, anhydrous sodium sulfate and anhydrous zinc sulfate in a mass ratio of 0.10:4:1.5:1.3, it enters the reactor through a reflux device; after the reaction The material is treated with a mixed organic amine composed of ethylamine, diethylamine, triethylamine, propylamine, dipropylamine, and tripropylamine in a mass ratio of 0.5: 0.8: 0.6: 0.7: 0.10: 0.3, and the pH value of the reaction material is adjusted 7.2, and after stirring for 5 hours, add anhydrous magnesium sulfate and / or anhydrous sodium sulfate to dry the reaction mass percentage of 30%; the dried material is filtered or centrifuged to separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com