Structure of bracket for long lead screw

A bracket structure, long lead screw technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., to achieve the effect of expanding the range of use, easy installation and operation, and obvious use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

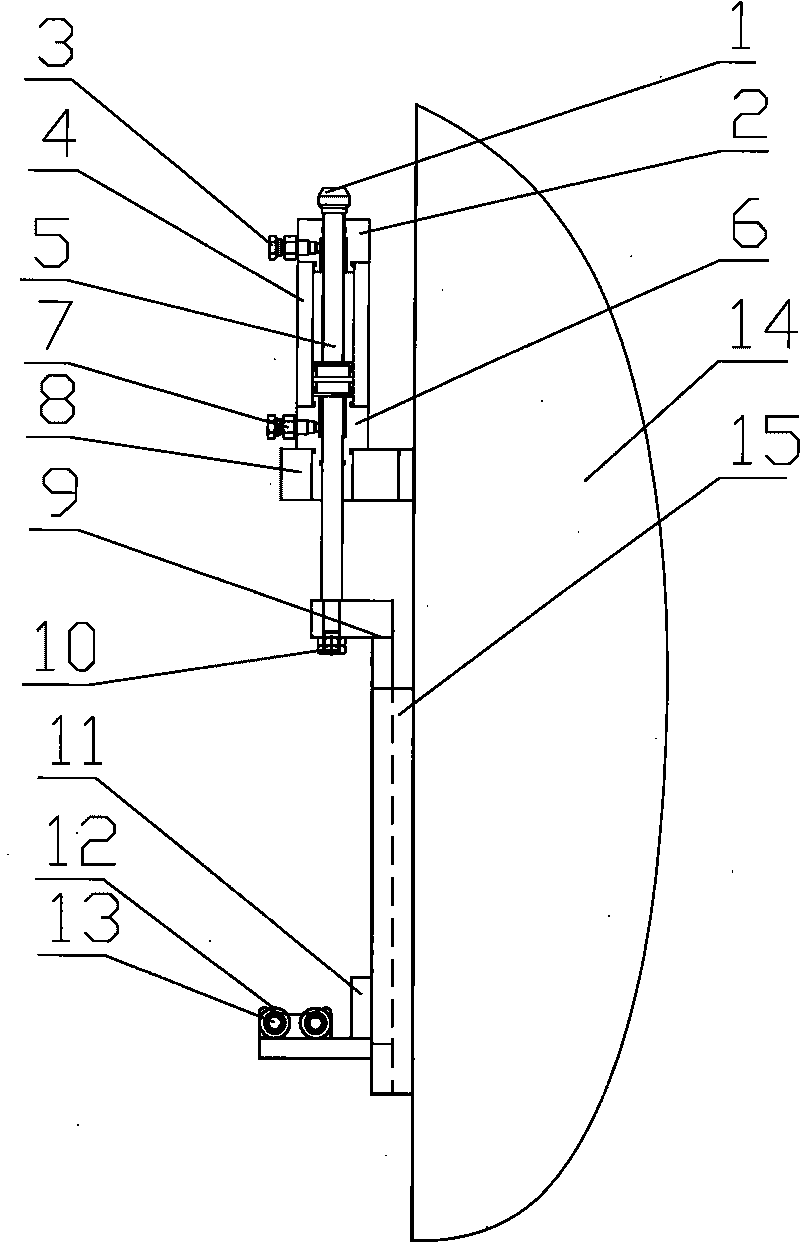

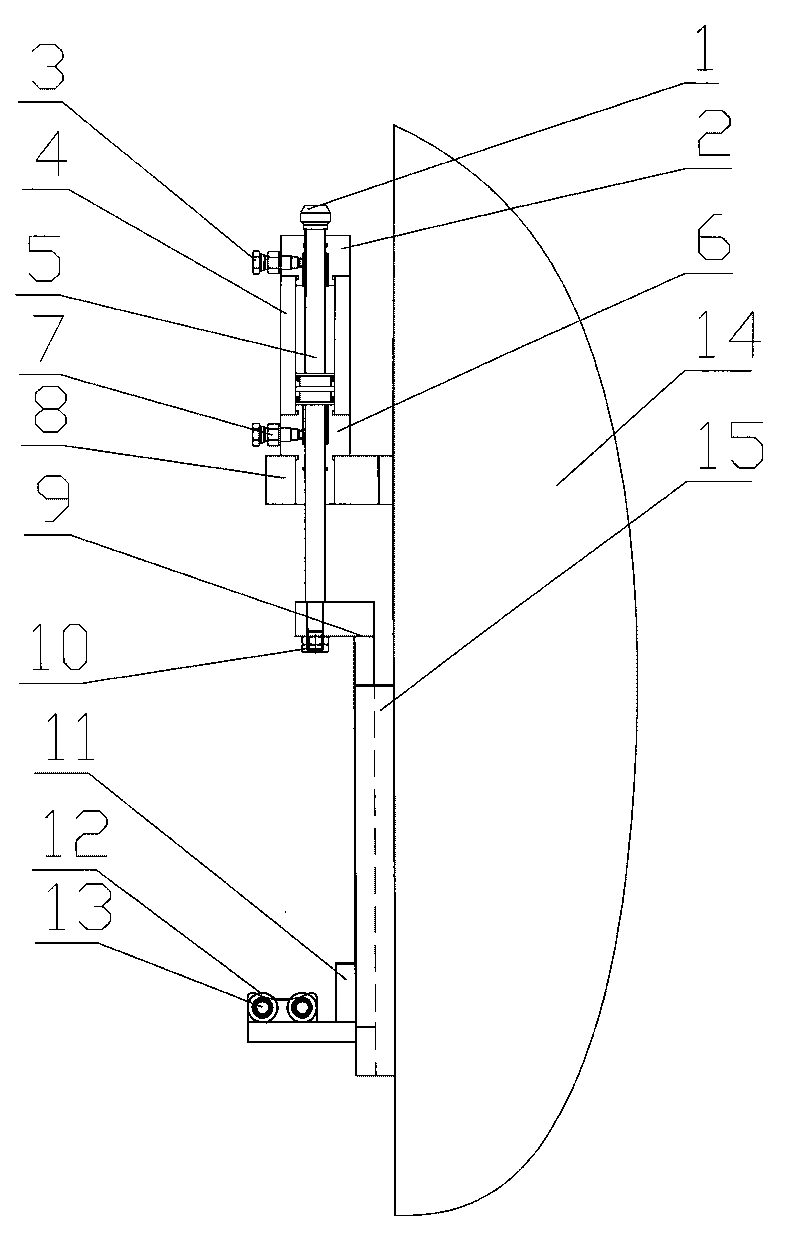

[0011] Such as figure 1 Shown: including sending cover 1, first oil cylinder end cover 2, first oil pipe joint 3, cylinder body 4, piston rod 5, second oil cylinder end cover 6, second oil pipe joint 7, oil cylinder seat 8, guide rail 9, Nut 10, bracket 11, roller 12, roller shaft 13, beam 14 and guide rail guide seat 15.

[0012] In the present invention, the first oil cylinder end cover 2, the cylinder body 4, and the second oil cylinder end cover 6 are fastened and connected together by screws to form the oil cylinder body, and the piston rod 5 is arranged in the cylinder body to separate the inner chamber of the oil cylinder to form the upper and lower chambers; The sending cover 1 is installed on the top of the piston rod 5, and the lower end of the piston rod 5 is connected to the connecting part of the guide rail 9 bracket through the nut 10; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com