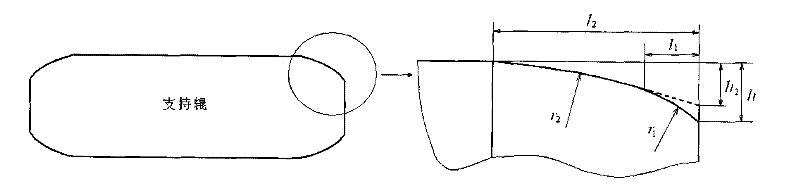

A kind of variable contact backup roll for rolling plate and strip and its processing method

A technology of supporting rolls and variable contact, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as inability to adjust roll shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0111] The roll shape curve is designed with the coefficients selected in Table 1, such as Figure 7 As shown in the middle roll shape 1, it can be seen that when all roll shape angles are taken as 0, the roll shape is a conventional flat roll.

[0112] Table 1

[0113] Coefficient

Embodiment approach 2

[0115] The roll shape curve is designed with the coefficients selected in Table 2 as Figure 7 As shown in the middle roll shape 2, it can be seen that the roll shape has obvious variable contact characteristics. Since the selection of the shape angle is small and the roll shape adjustment coefficient is selected to the maximum value, the depth of the variable contact section and the chamfer section of the roll shape curve are uniform. Larger, the maximum roll diameter difference of the roll shape has reached more than 2.5mm, and this roll shape is generally suitable for occasions with large rolling forces.

[0116] Table 2

[0117] Coefficient

Embodiment approach 3

[0119] The roll shape curve is designed with the coefficients selected in Table 3 as Figure 7 As shown in the middle roll shape 3, it can be seen that the roll shape has variable contact characteristics, and the maximum roll diameter difference is about 1.4mm, which is generally suitable for the upstream stand of the hot rolling mill.

[0120] table 3

[0121] Coefficient

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com