Ultra-wide plate strip six-roll cold-rolling mill type

A technology of ultra-wide plate and cold rolling mill, applied in the direction of metal rolling mill stands, metal rolling stands, rolls, etc., can solve the problems of inability to roll strips, reduce the contact area, improve the control effect, Effects of Improving Roll Gap Transverse Rigidity and Roll Bending Force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

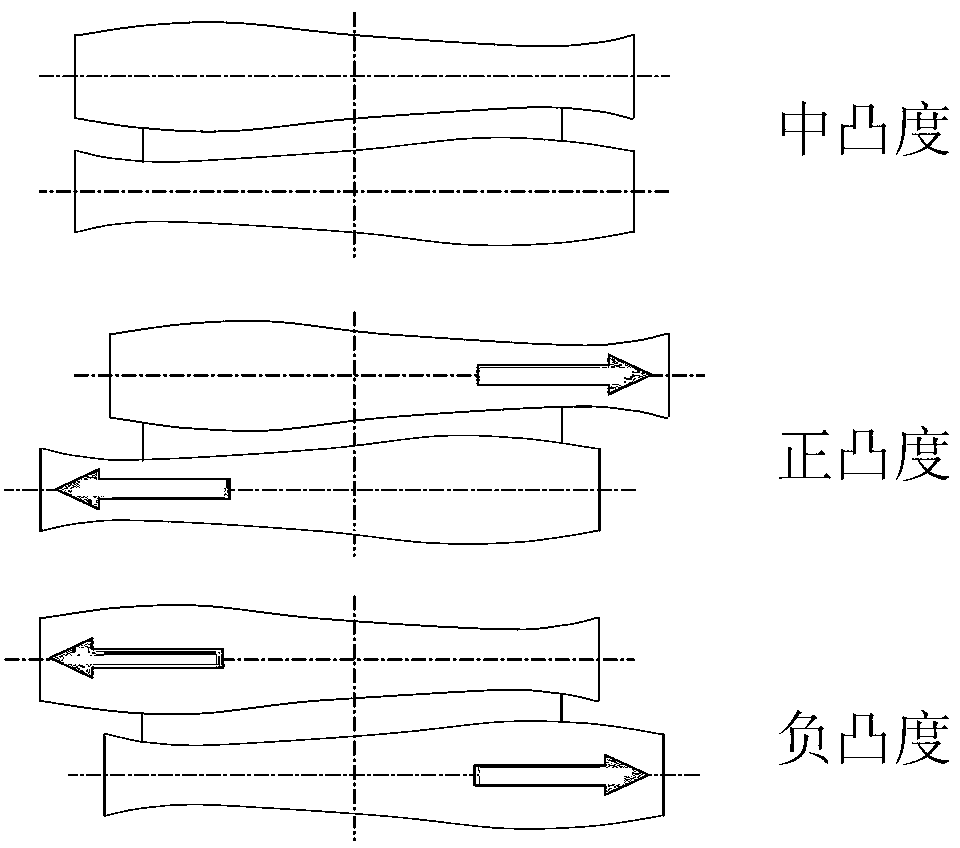

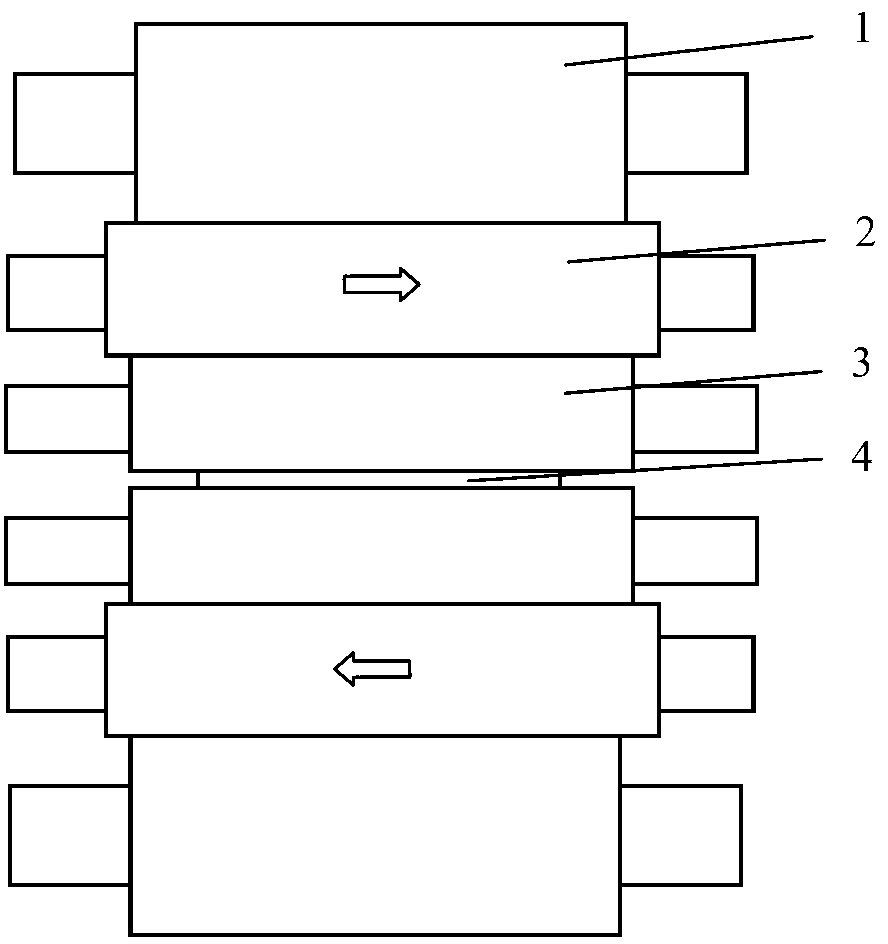

[0087] For a 3000mm rolling mill, the back-up roll body length L is known B =3000mm, diameter D B =1500mm; middle roll body length L m =3400mm, diameter D m =700mm; working roll body length L w =3000mm, diameter D w =600mm; limit value s of rolling mill positive and negative roll shifting m =200mm; the maximum and minimum rollable width of the rolling mill are respectively B max =2800mm, B min =1200mm.

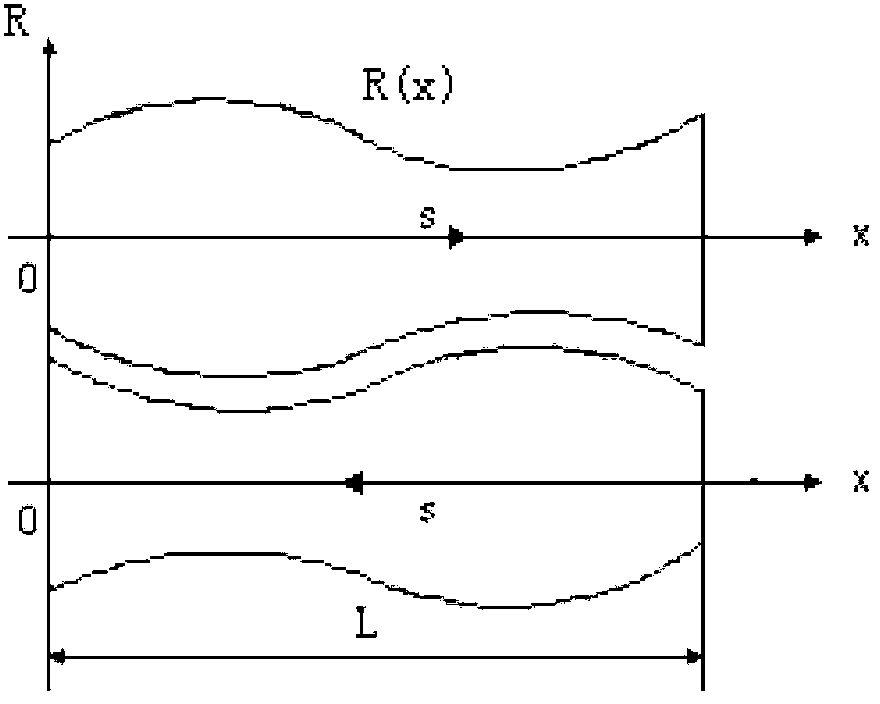

[0088] Within the range of rollable width, the intermediate roll can adopt variable crown roll shape, and the roll shape curve can be designed as:

[0089] y(x)=R 0 +a 1 x+a 2 x 2 +a 3 x 3 +a 4 x 4 +a 5 x 5

[0090] Among them, the roll shape parameter is a 1 =1.03916×10 -3 , a 2 =2.80064×10 -8 mm -1 , a 3 =-5.53883×10 -10 mm -2 , a 4 =2.28624×10 -13 mm -3 , a 5 =-2.54026×10 -17 mm -4 . Specific model configuratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com