Three-level midpoint potential balance control method based on zero sequence voltage injection

A technology of zero-sequence voltage and potential balance, applied in electrical components, output power conversion devices, AC power input conversion to AC power output, etc., can solve problems such as complex calculations and high-precision acquisition circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

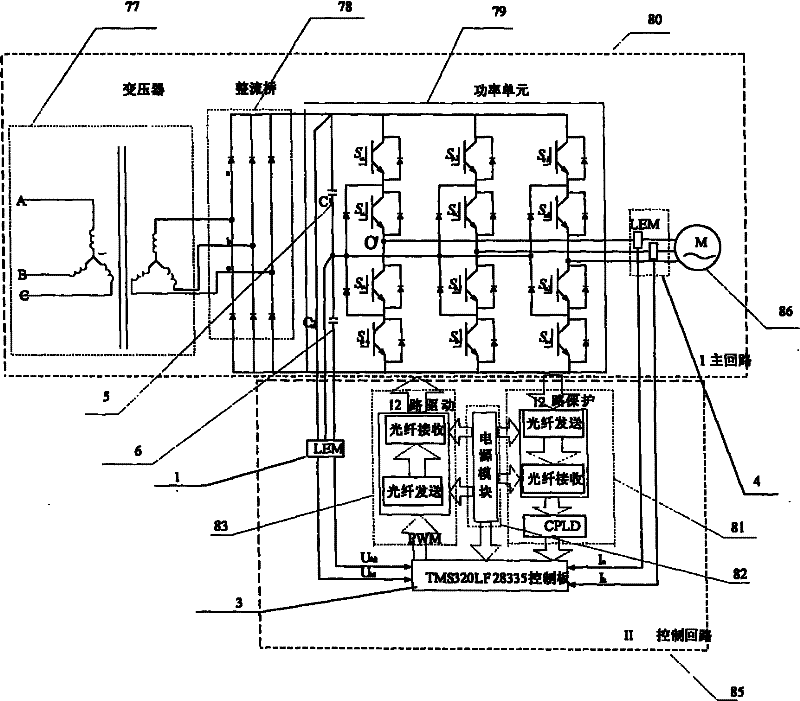

[0117] figure 1 It is a three-level inverter control system structure diagram, which mainly includes two main loops 80 and a control loop 85. The main circuit 80 is composed of a transformer 77, a rectifier bridge 78, a three-level inverter 79, and a motor load 86; the control circuit 85 includes a DSP control board 3, 12 PWM optical fiber sending and receiving circuits 83, and 12 fault signal optical fiber sending and receiving circuits. Receiving circuit 81, power supply module 82. In the main circuit 80, the transformer 77 is connected to the rectifier bridge 78. The rectifier bridge 78 converts the three-phase AC power provided by the transformer 77 into DC power for the three-level inverter 79. The rectifier bridge 78 is connected to the three-level inverter 79 , The inverter 79 is connected to the motor 86, the three-level inverter 79 converts the DC power output from the rectifier bridge 78 into a three-phase AC of the desired frequency f, and supplies it to the motor l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com