Lithium ion battery cell packet preparation method and system

A lithium-ion battery and preparation system technology, which is applied in the field of lithium-ion battery core pack preparation, can solve problems such as affecting the alignment of cells, hidden dangers of core pack reliability, affecting the performance of cells, etc., so as to improve reliability and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

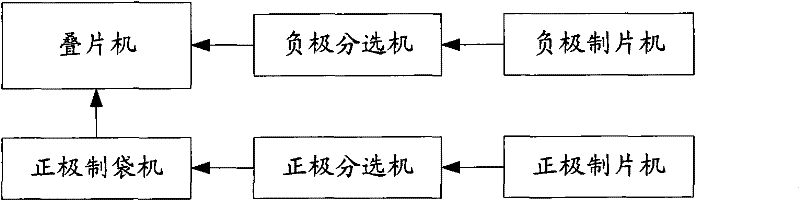

[0091] Lithium-ion battery core pack preparation method of the present invention, one embodiment thereof, comprises the following steps:

[0092] The pole sheet material is made into a negative electrode sheet by a negative electrode sheet making machine, and the negative electrode sheet is transferred to a negative electrode separator by a first conveying device;

[0093] Select qualified negative electrode sheets from the negative electrode sheets through the negative electrode sorting machine according to a predetermined standard, and transfer the qualified negative electrode sheets to the stacking machine through the second conveying device;

[0094] Pole sheet material is made into a positive electrode sheet by a positive electrode sheet making machine, and the positive electrode sheet is transferred to a positive electrode separator by a third conveying device;

[0095] Select qualified positive electrode sheets from the positive electrode sheets by the positive electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com