Dye solar battery structure and manufacturing method of light absorption reaction layer thereof

A technology of solar cells and manufacturing methods, applied in the direction of capacitor electrolyte/absorbent, electrical components, photosensitive equipment, etc., to achieve the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

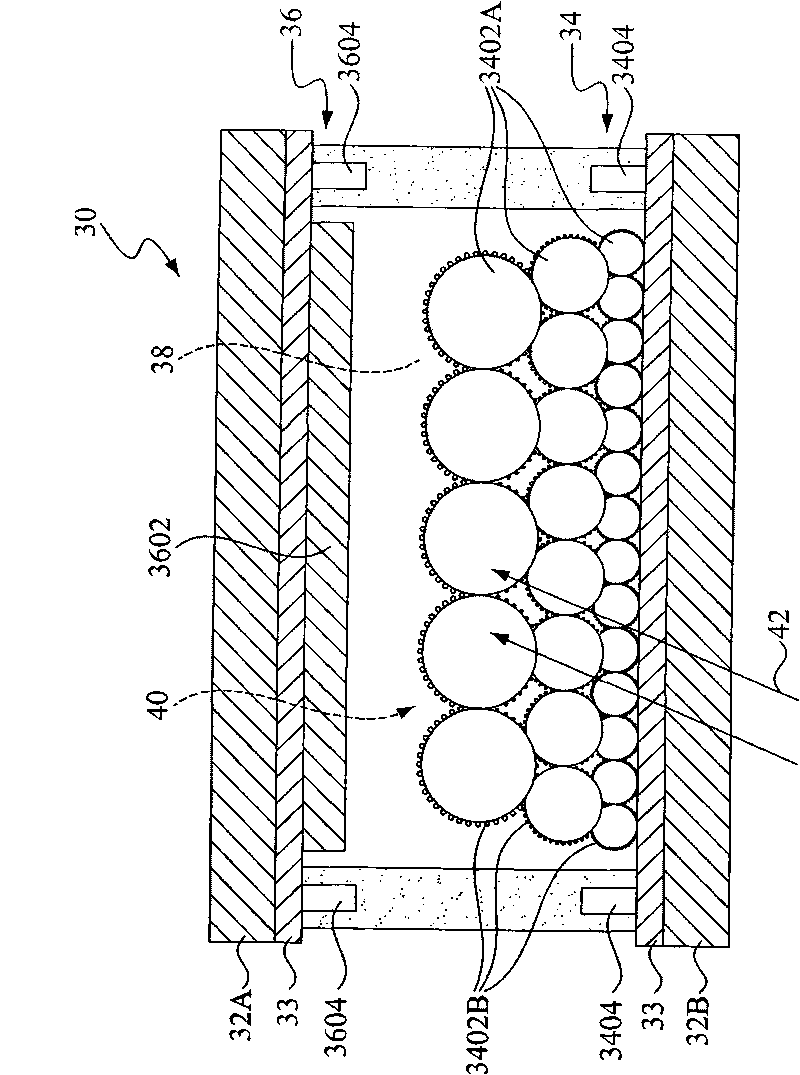

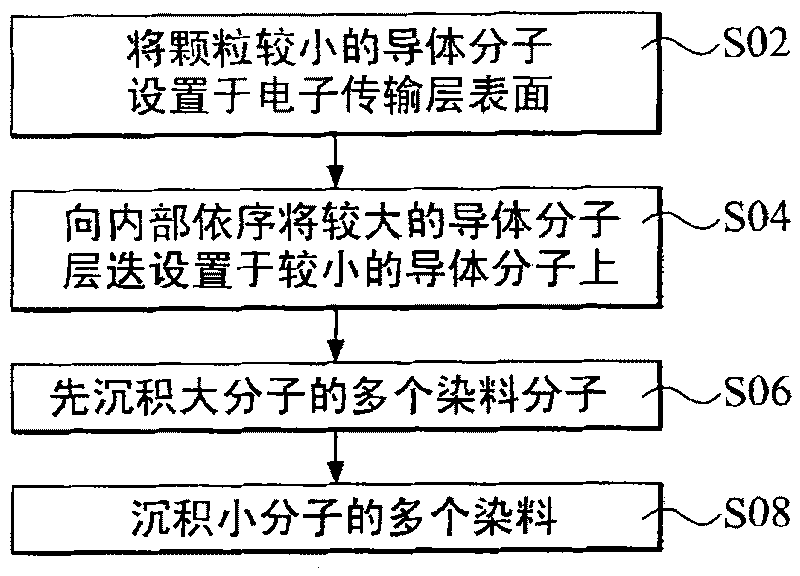

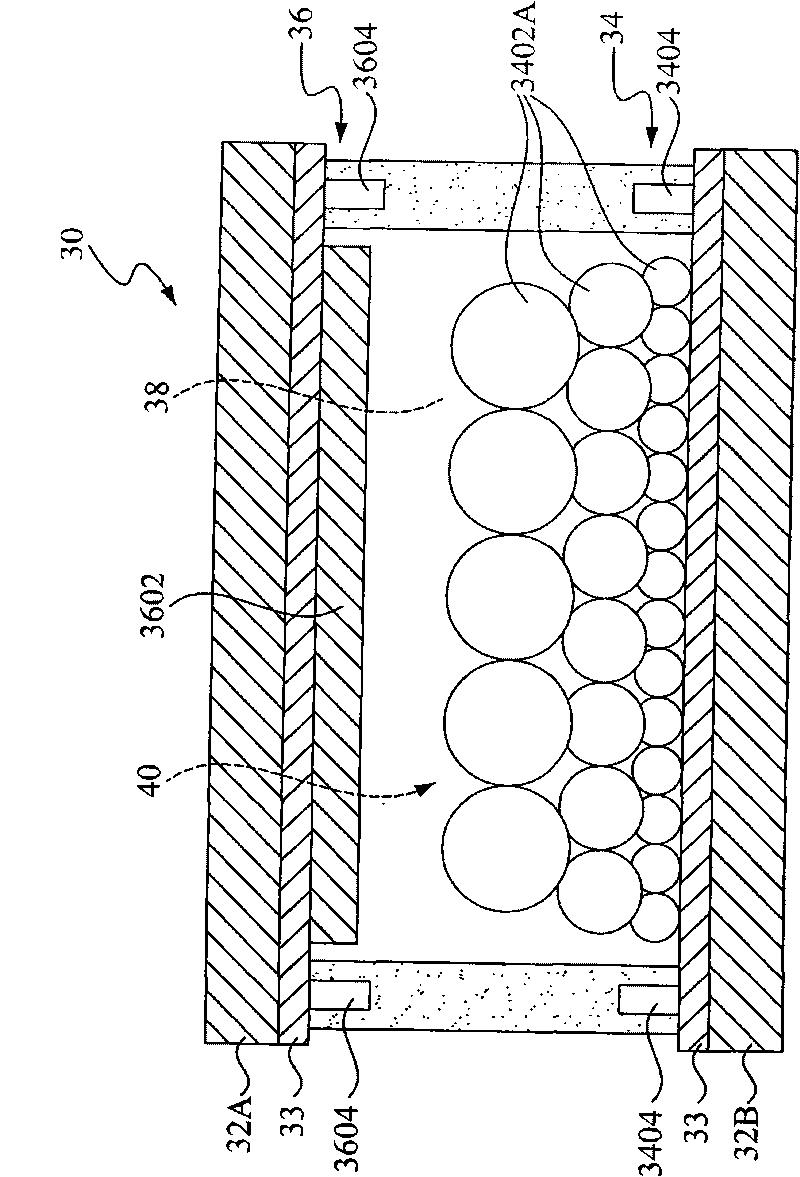

[0029] see figure 1 , figure 1 It is a side cross-sectional view of the dye solar cell structure 30 of the present invention. The present invention relates to a dye solar cell structure 30 , which can increase the absorption rate of light 42 and expand the spectral range absorbed by light 42 , thereby increasing the overall photoelectric conversion efficiency. The dye solar cell structure 30 includes a substrate 32A, a transparent substrate 32B, two electron transport layers 33 , a light absorbing reaction layer 34 , and a pair of polar layers 36 .

[0030] The transparent substrate 32B is stacked against the substrate 32A to form an interior 40 between the substrate 32A and the transparent substrate 32B. In practice, the substrate 32A can be the transparent substrate 32B, and the so-called transparent substrate 32B can be a glass substrate. The light 42 enters the interior 40 through the transparent substrate 32B from the outside relative to the interior 40 .

[0031] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com