Panel pressing detection device and pressing mechanism

A detection device and panel technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as easy loopholes, eye fatigue of inspectors, and difficulty in precise control of power, so as to improve inspection quality and solve manpower and safety problems , to avoid the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the accompanying drawings.

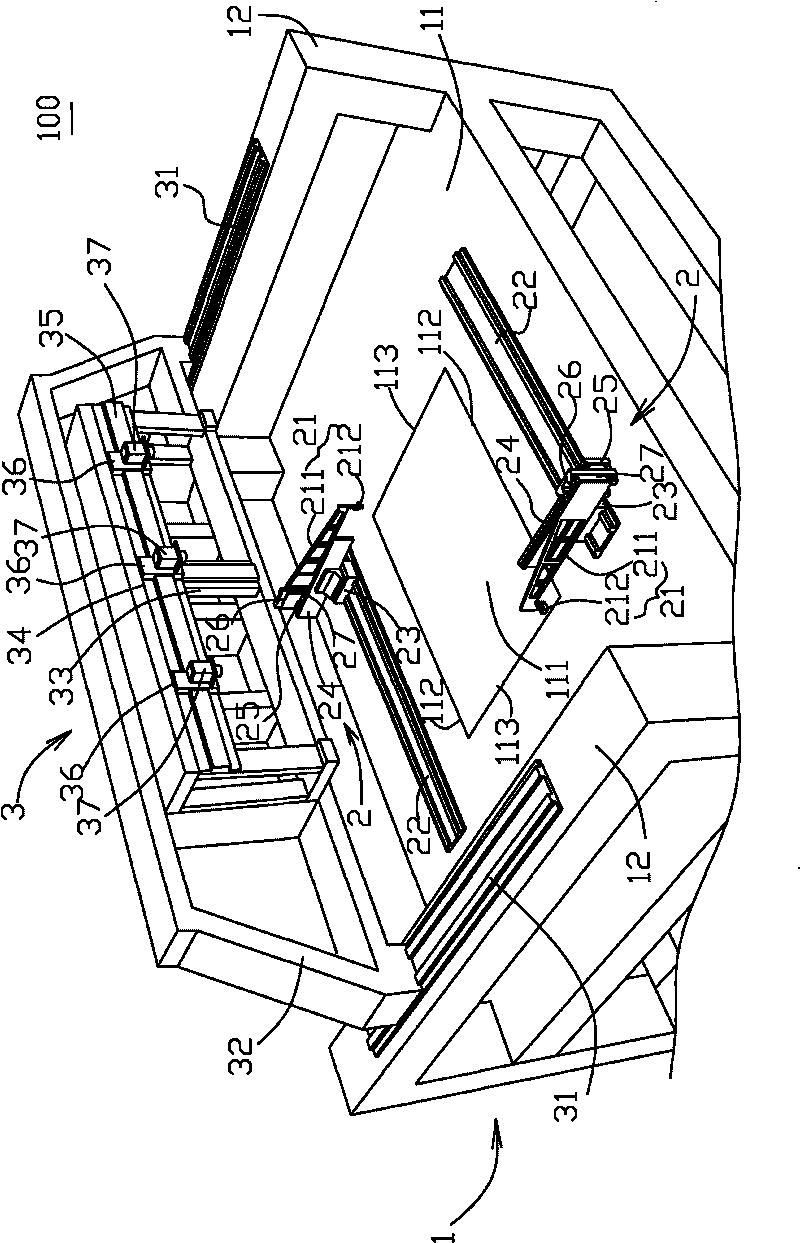

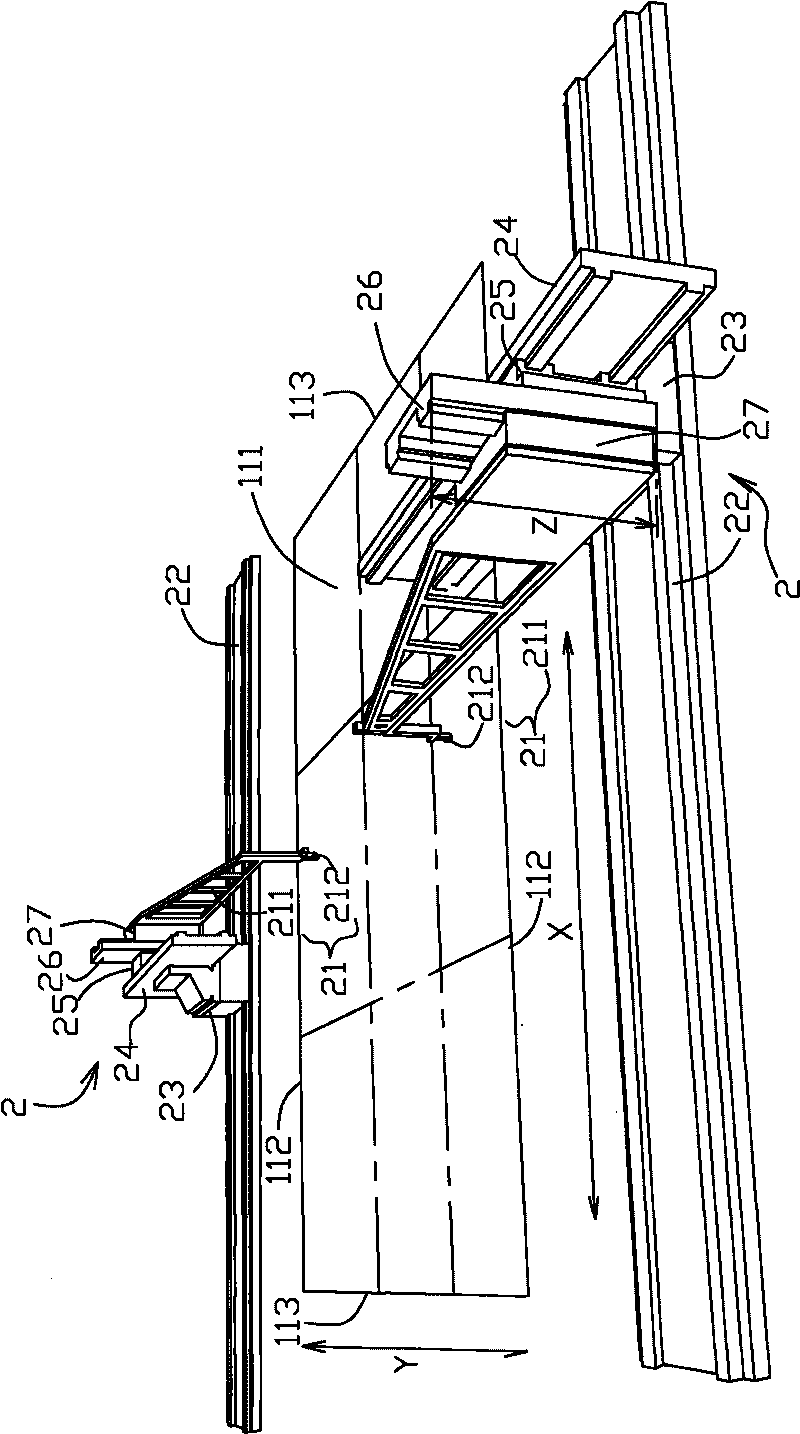

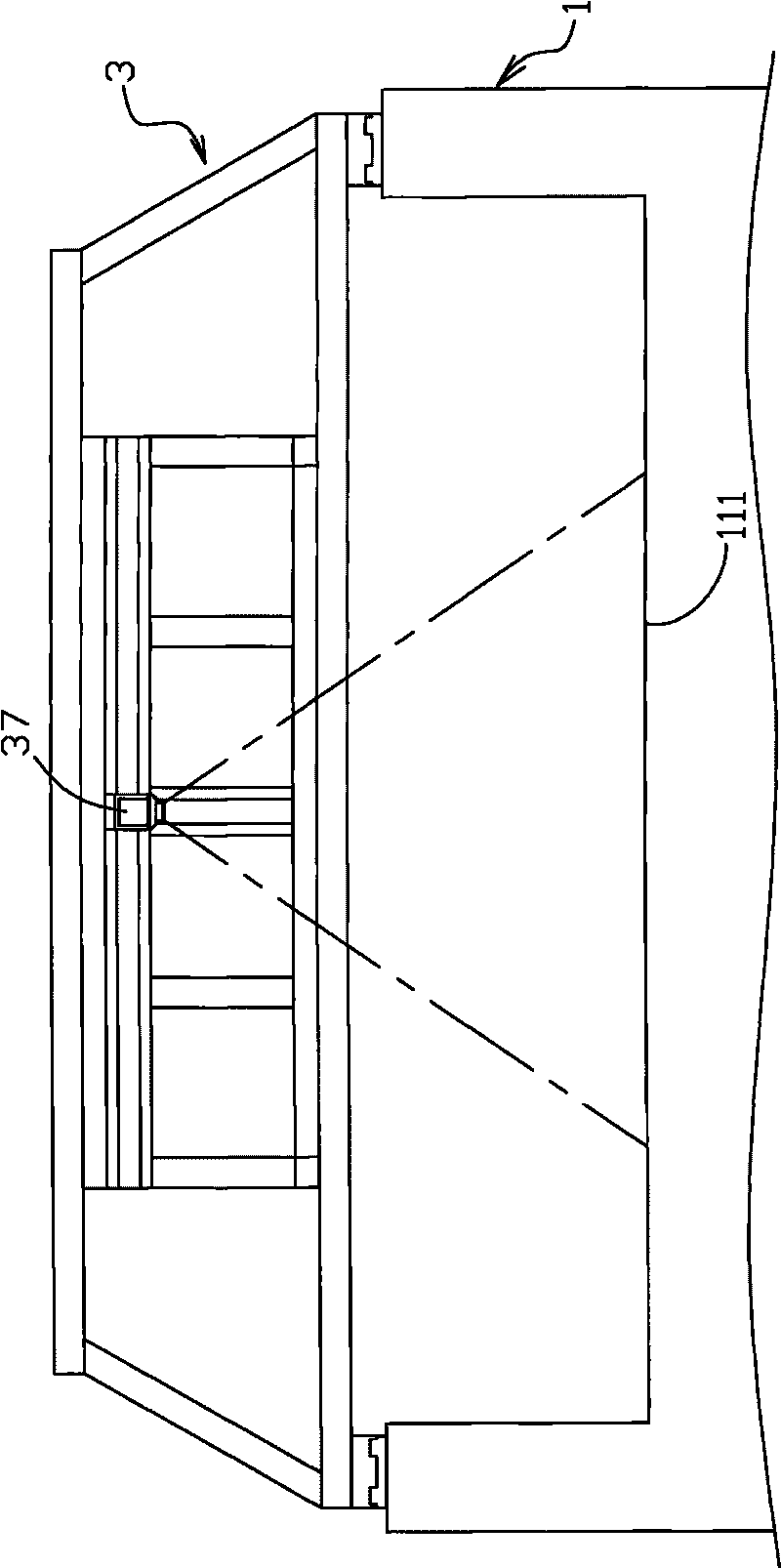

[0035] figure 1 and figure 2 Shown is a preferred embodiment of the panel pressing detection device 100 of the present invention, the panel pressing detection device 100 is suitable for detecting a driven liquid crystal display panel (not shown), and includes a machine 1, two pressing mechanisms 2 and An imaging unit 3 .

[0036] The machine 1 includes a testing platform 11 for placing the panel, and two racks 12 respectively extending upward from both sides of the testing platform 11 . There is a panel accommodating portion 111 at the center of the detection platform 11 , and the liquid crystal display panel is removably placed in the panel accommodating portion 111 . The shape of the panel accommodating part 111 is a rectangle corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com