Bearing cage

A technology of bearing retainer and retainer, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of troublesome use and difficult grinding process in the later stage, and achieve the effects of convenient and simple processing, simplified process and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

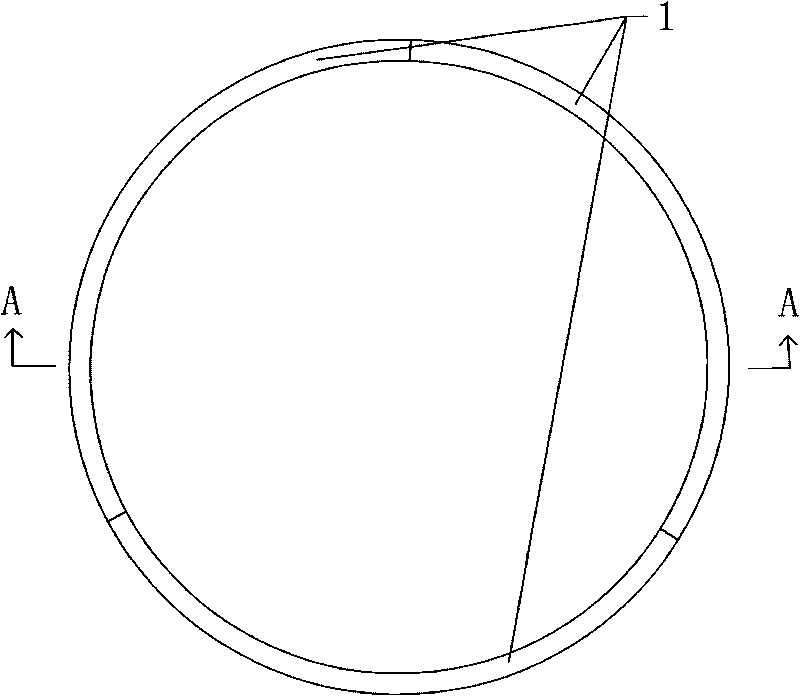

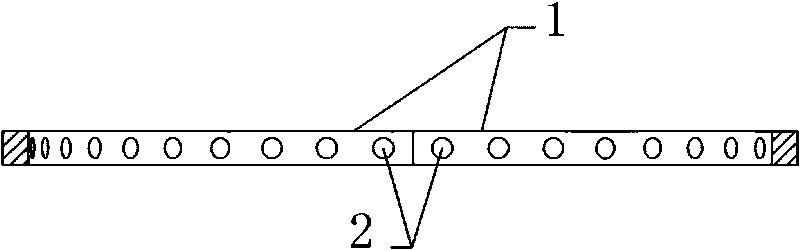

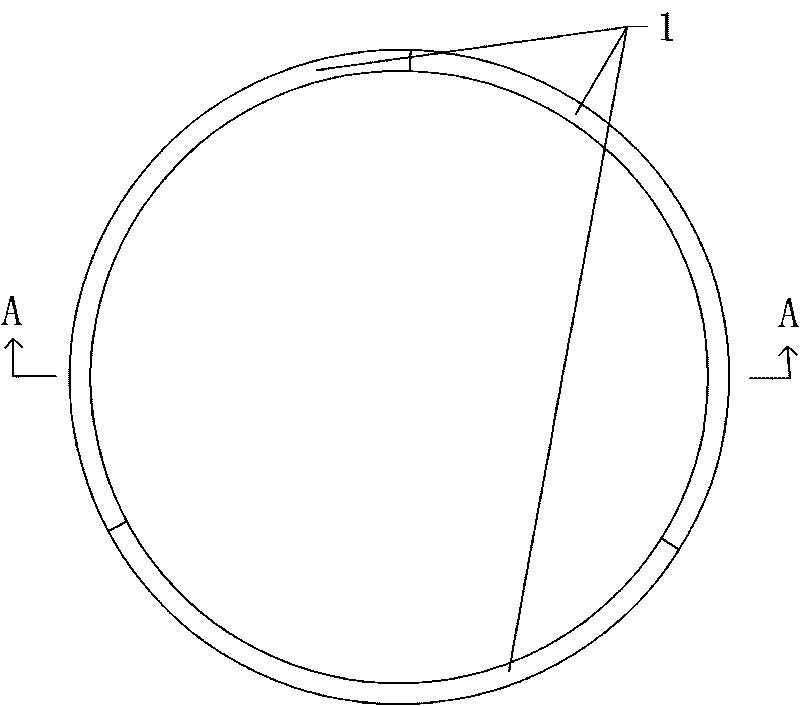

[0011] Such as figure 1 , 2 As shown, the bearing retainer is ring-shaped and consists of three arc-shaped retaining pieces 1 with the same shape and size. The radian of the holding piece 1 is 120 degrees, so that the three sections of holding piece 1 form a complete circle. A plurality of window holes 2 are provided on the concave side of each holding piece 1, and the window holes 2 are used to fix various supports, such as balls and rollers. In order to make the supports fixed on the bearing holder evenly distributed, the window holes 2 on each section of the holding piece 1 are evenly distributed, and the distance from the window hole 2 at any end of the holding piece 1 to the corresponding end of the holding piece 1 is adjacent. 1 / 2 of the distance between the window holes 2, which ensures that the distance between the window holes 2 at the adjacent ends of the two sections of the retaining sheet 1 is the same as the whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com