Waste water recycling pad dyeing long machine and waste water recycling method thereof

A waste water and pad dyeing technology, applied in textile and papermaking, textile processing machine accessories, textile material processing and other directions, can solve problems such as environmental pollution, waste of water resources, low efficiency, etc., to reduce production costs, save production water, The effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

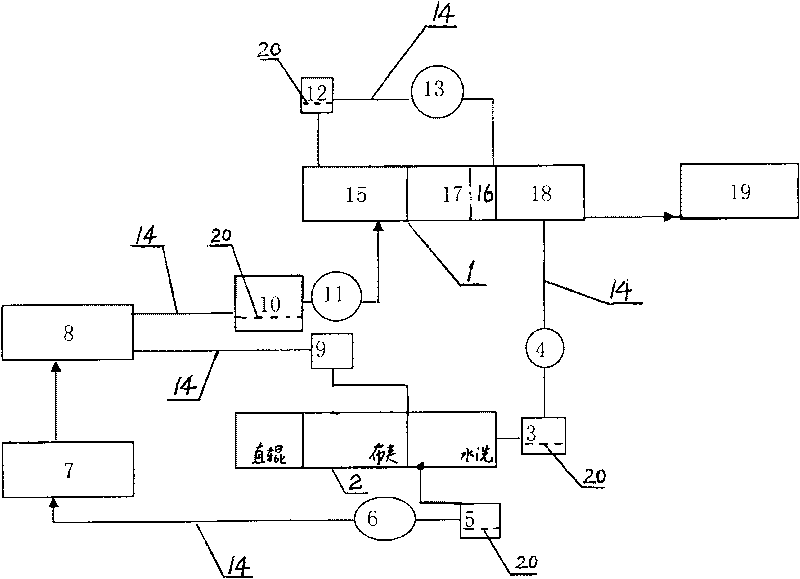

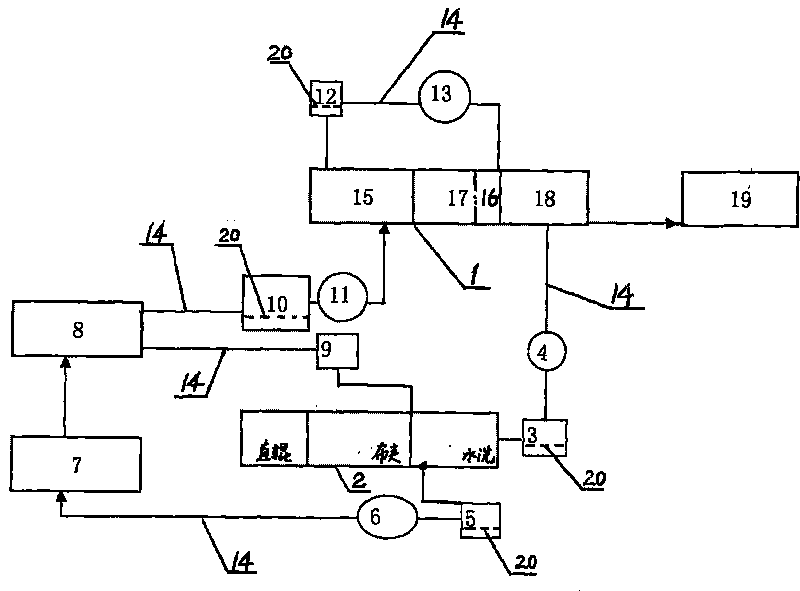

[0010] Embodiment 1: as figure 1 As shown, the waste water reuse pad dyeing long car includes descouring and bleaching combined machine 1, mercerizing machine 2, No. 1 recovery treatment box 3, No. 1 recovery pump 4, No. 3 recovery box 5, No. 3 recovery pump 6, light alkali Recovery pool 7, expansion evaporator 8, alkali distribution pool 9, recovery pool 10, recovery pump 11, No. 2 recovery treatment box 12, No. 2 recovery pump 13 and connecting pipeline 14, No. 1 recovery treatment box 3 one end passes through pipeline 14 and The second half of the mercerizing machine 2 is connected to the washing wastewater, and the other end is connected to the scouring machine 18 of the descouring and bleaching combined machine 1 through the pipeline 14 and the No. 1 recovery pump 4. One end of the No. 3 recovery box 5 is connected to the first half of the mercerizing machine 2 through the pipeline 14 The light alkali after mercerized water washing is connected, and the other end is conne...

Embodiment 2

[0011] Embodiment 2: waste water reuse The waste water reuse method of the pad dyeing long car is: a. the second half of the mercerizing machine 2 washing waste water is connected to the No. 1 recovery treatment box 3 through the pipeline 14, and the No. 1 recovery pump 4 is used for filtering Put into the scouring machine 18 of the descouring and bleaching combined machine 1, b. the light alkali after the first half of the mercerizing water washing of the mercerizing machine 2 is connected to the light alkali recovery pool 7 through the No. 3 recovery box 5 and the No. 3 recovery pump 6 through the pipeline 14 , c. the light alkali in the light alkali recovery pool 7 is connected to the expansion evaporator 8 through the pipeline 14 for processing: 1. After the treatment, the concentrated lye with a concentration of more than 200 grams is connected to the mercerizing machine 2 through the pipeline 14 through the alkali distribution pool 9 ② The water after treatment is put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com