Heavy oil auxiliary

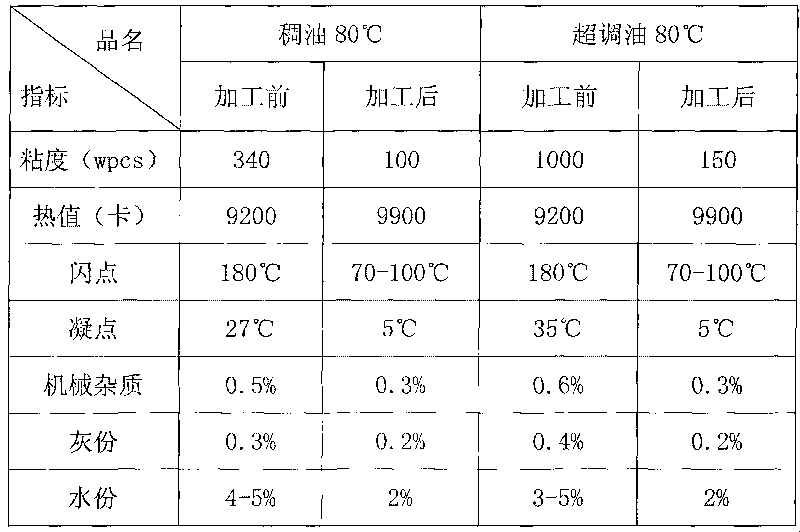

A technology for heavy oil and additives, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of difficult processing of heavy oil, difficult unified processing, high freezing point, etc., and achieve complete combustion, convenient transportation, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 18kg of 0# diesel oil, 20kg of biodiesel, 12kg of viscosity reducer, 12kg of decomposition agent, 15kg of smoke remover, 15kg of naphthenic acid, and 8kg of stabilizer at 70°C for 4 hours to prepare a heavy oil additive.

Embodiment 2

[0022] Take 30kg of 0# diesel oil, 12kg of biodiesel, 12kg of viscosity reducer, 10kg of decomposition agent, 15kg of smoke remover, 15kg of naphthenic acid, and 6kg of stabilizer at 100°C for 4.5 hours to prepare a heavy oil additive.

Embodiment 3

[0024] Take 26kg of 0# diesel oil, 18kg of biodiesel, 11kg of viscosity reducer, 11kg of decomposer, 14kg of smoke remover, 12kg of naphthenic acid, and 8kg of stabilizer at 86°C for 4 hours to prepare a heavy oil additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com