Compound modified asphalt preparation device and preparation method

A composite modified asphalt and controller technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as complex preparation methods, air pollution, instability, etc., and achieve the effect of simplifying complex procedures and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

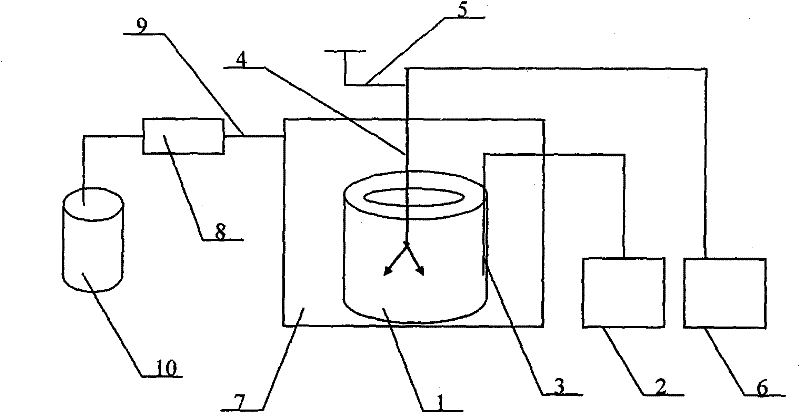

[0019] Such as figure 1 Shown:

[0020] The heater 1 has inner and outer layers, and the detection head 3 of the temperature controller 2 is set in the inner and outer spaces of the heater 1; the high-temperature stirrer 4 is fixed on the shelf 5 and connected to the speed controller 6 at the lower end Placed in heater 1; heater 1 is placed in safety explosion-proof incubator 7; temperature controller 2 and speed controller 6 are placed outside of safety explosion-proof incubator 7; one end of condenser tube 8 is connected to safety explosion-proof insulation with glass tube 9 The other end of the opening of the box 7 is connected to the collection bottle 10.

[0021] Placing the heater 1 in the safety explosion-proof incubator 7 can not only prevent the heater 1 from exploding due to overheating, but also maintain a good temperature environment and reduce the influence of the external temperature difference during the preparation process. The detection head 3 is used to sense the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com