Method for preparing PC-g-PMMA grafted copolymer by adopting electron beam irradiation method

A technology of graft copolymer and electron beam irradiation, which is applied in the field of preparation of PC-g-PMMA graft copolymer, can solve the problems such as complex synthesis process, and achieve the effect of simple process, improved compatibility and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

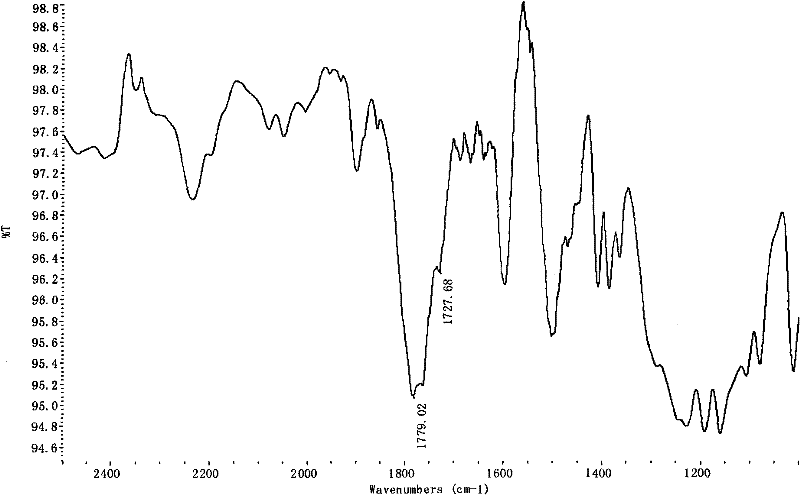

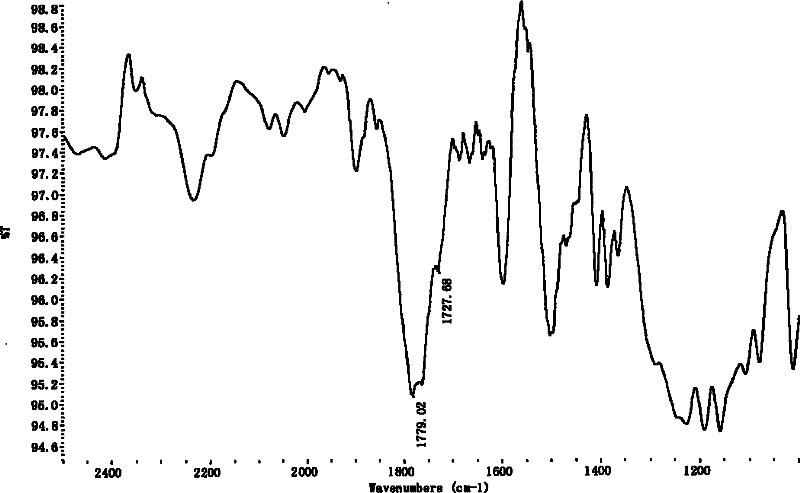

[0021] Example 1: An appropriate amount of PC powder is placed in a PE ziplock bag for electron beam pre-irradiation treatment, and the irradiation dose is 15KGray. The above pre-irradiated PC powder was immersed in the monomeric MMA, and the catalyst FeSO was added 4 and H 2 SO 4 , according to the amount of MMA added, calculate the addition amount of catalyst, make its concentration in the system be 0.001mol / L and 0.1mol / L respectively. The reaction was carried out under nitrogen protection condition for 6 hours, and the reaction temperature was kept at 60°C. The reaction product was filtered by suction, soaked in acetone and washed several times, then washed several times with deionized water and finally dried under vacuum at 80° C. for 24 hours. The FT-IR figure of the obtained PC-g-PMMA graft copolymer sees figure 1 , 1727cm -1 The nearby characteristic peaks prove the occurrence of grafting reaction.

[0022] The preparation of PC / PMMA blend: a certain amount of PC...

Embodiment 2

[0023] Example 2: The PC film is placed in a PE ziplock bag for electron beam pre-irradiation treatment, and the irradiation dose is 30KGray. The above pre-irradiated PC powder was immersed in the monomer MMA and the solvent butyl acetate, the volume ratio (MMA to butyl acetate) was 1:2, and the catalyst FeSO 4 and H 2 SO 4 , according to the amount of added MMA and solvent, calculate the amount of catalyst that needs to be added, so that its concentration in the system is 0.001mol / L and 0.1mol / L respectively. The reaction was carried out under nitrogen protection condition for 6 hours, and the reaction temperature was kept at 90°C. The reaction product was filtered by suction, soaked in acetone and washed several times, then washed several times with deionized water and finally dried under vacuum at 80° C. for 24 hours. The FT-IR figure of the obtained PC-g-PMMA graft copolymer sees figure 1 , 1727cm -1 The nearby characteristic peaks prove the occurrence of grafting rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com