Water-based drag reducer and application thereof

A drag reducer, water-based technology, applied in the field of drag reducer, can solve problems such as unsatisfactory application effect and no practical value, and achieve the effects of scientific equipment and verification methods, highlighting technological progress, and great energy-saving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

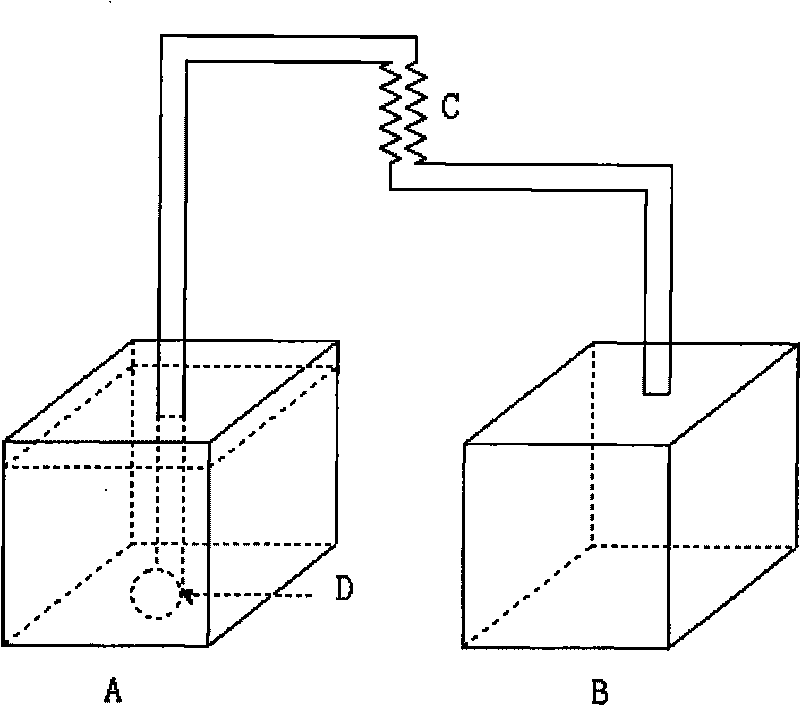

[0055] Example ( figure 1 )

[0056] Composition of water-based drag reducer: non-ionic surfactant fatty alcohol polyoxyethylene ether AEO-9 40ppm; methyl polysiloxane and nano-scale silicon dioxide as the main body, using a special emulsifier to emulsify the defoamer 8ppm , dodecyl dimethyl ammonium bromide fungicide 10ppm.

[0057] Such as figure 1 , as shown: the container A and container B of the device are two identical containers that can hold 15 liters of water, 30 cm high, with openings on the top, and are all placed on the ground; a submersible pump D is installed in the container A, and the power of the submersible pump D is 40 watts. The head is 160cm, the maximum flow rate is 2400 liters / hour; the outlet of submersible pump D is connected to plastic corrugated water pipe C, the diameter of water pipe C is 1.8cm, and the length is 500cm; 76cm, lay flat; the other end of the water pipe C is placed on top of the container B.

[0058] In application, the water and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com