Scissors-type accessible elevating platform

A lifting platform, barrier-free technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of affecting the service life and safe use of equipment, uncoordinated building appearance and environment, rust and corrosion of equipment steel structure, etc. Easy to maintain and not easy to accumulate water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

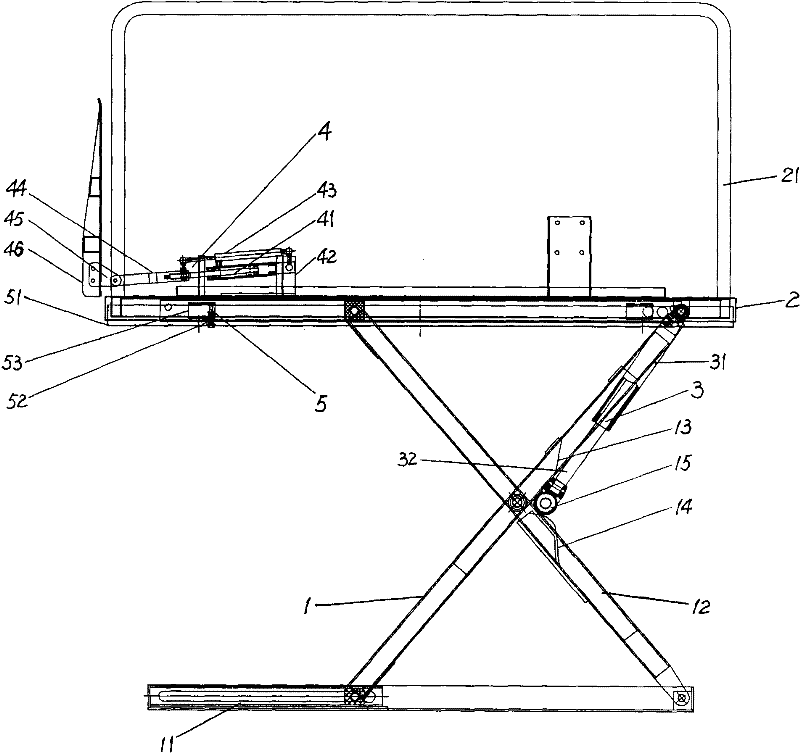

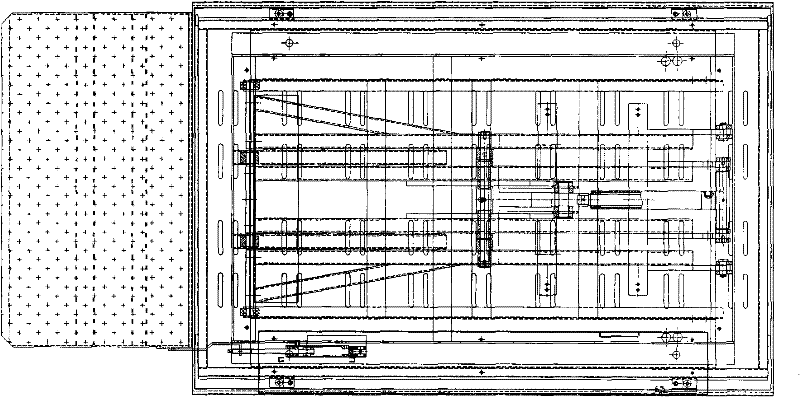

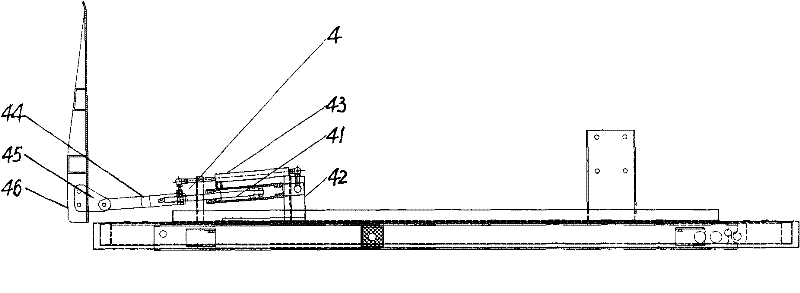

[0037] see figure 1 and figure 2 , A scissor-type barrier-free lifting platform of the present invention is mainly composed of a scissor-type frame 1, a lifting platform 2, a hydraulic cylinder lifting mechanism 3, an automatic flap mechanism 4 and a safety touch panel mechanism 5.

[0038] The scissor frame 1 includes an underframe 11 , a scissor-type inner and outer arm frame 12 , a slanting rail 13 , a cam plate 14 and cylinder rollers 15 . The bottom end of the scissor-type inner and outer arm frame 12 is placed on the bottom frame 11. The scissor-type inner and outer arm frame 12 can be made of seamless cold-drawn square tubes. The plate 14 is mounted on a jib below the said hinge and supports cylinder rollers 15 which are connected to the hydraulic cylinders.

[0039] Hydraulic cylinder lifting mechanism 3 is equipped with hydraulic cylinder 31, piston and hydraulic cylinder rod 32, and hydraulic cylinder 31 is installed on a jib upper end, and hydraulic cylinder rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com