Liquid filling and packing device

A technology for filling bags and liquids, which is applied in packaging, packaging protection, multiple packages, etc. It can solve the problems of filling liquid spraying or insufficient liquid, uncontrollable liquid level height, poor opening and closing accuracy, etc., to achieve extended use The effect of pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

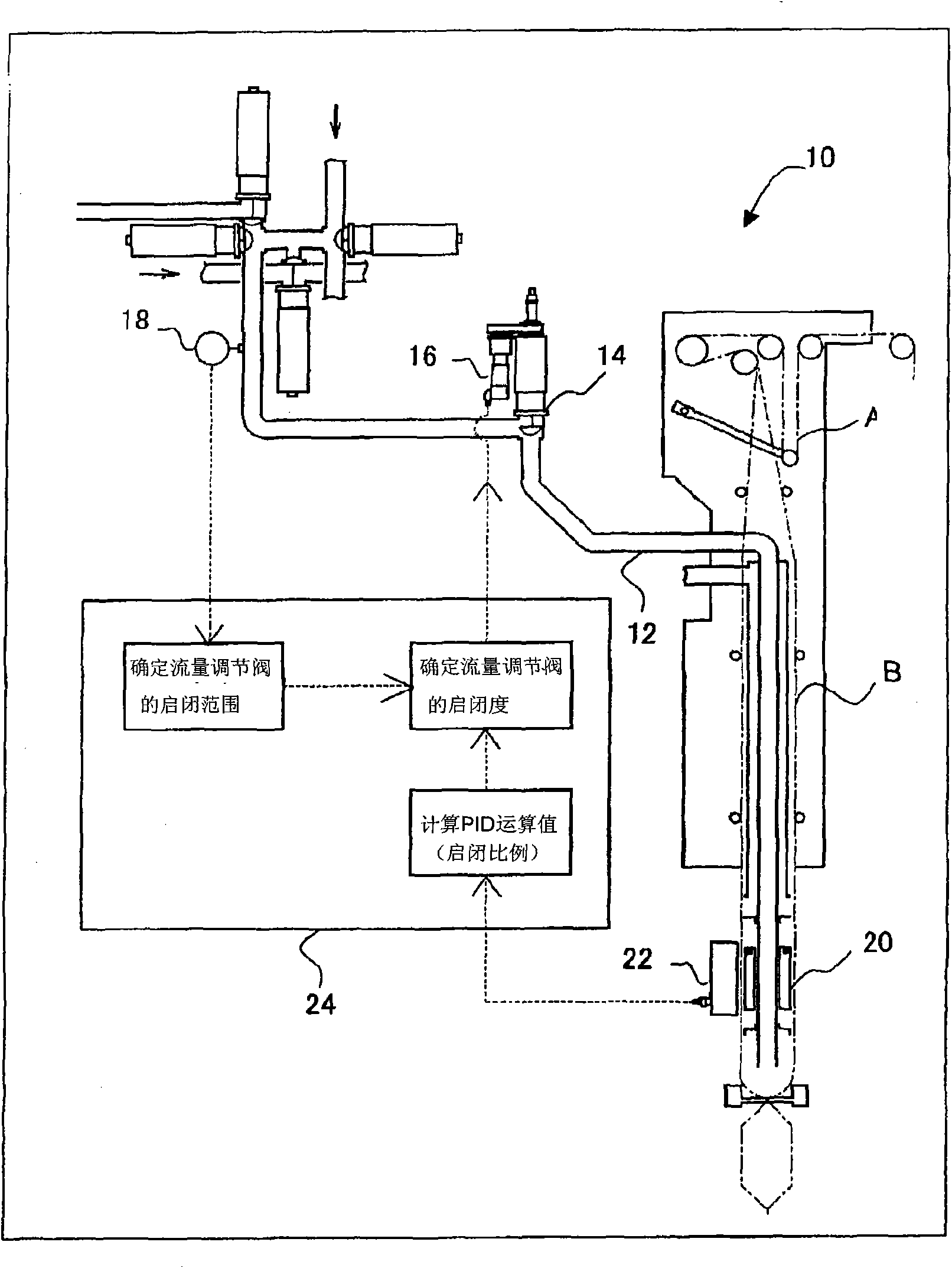

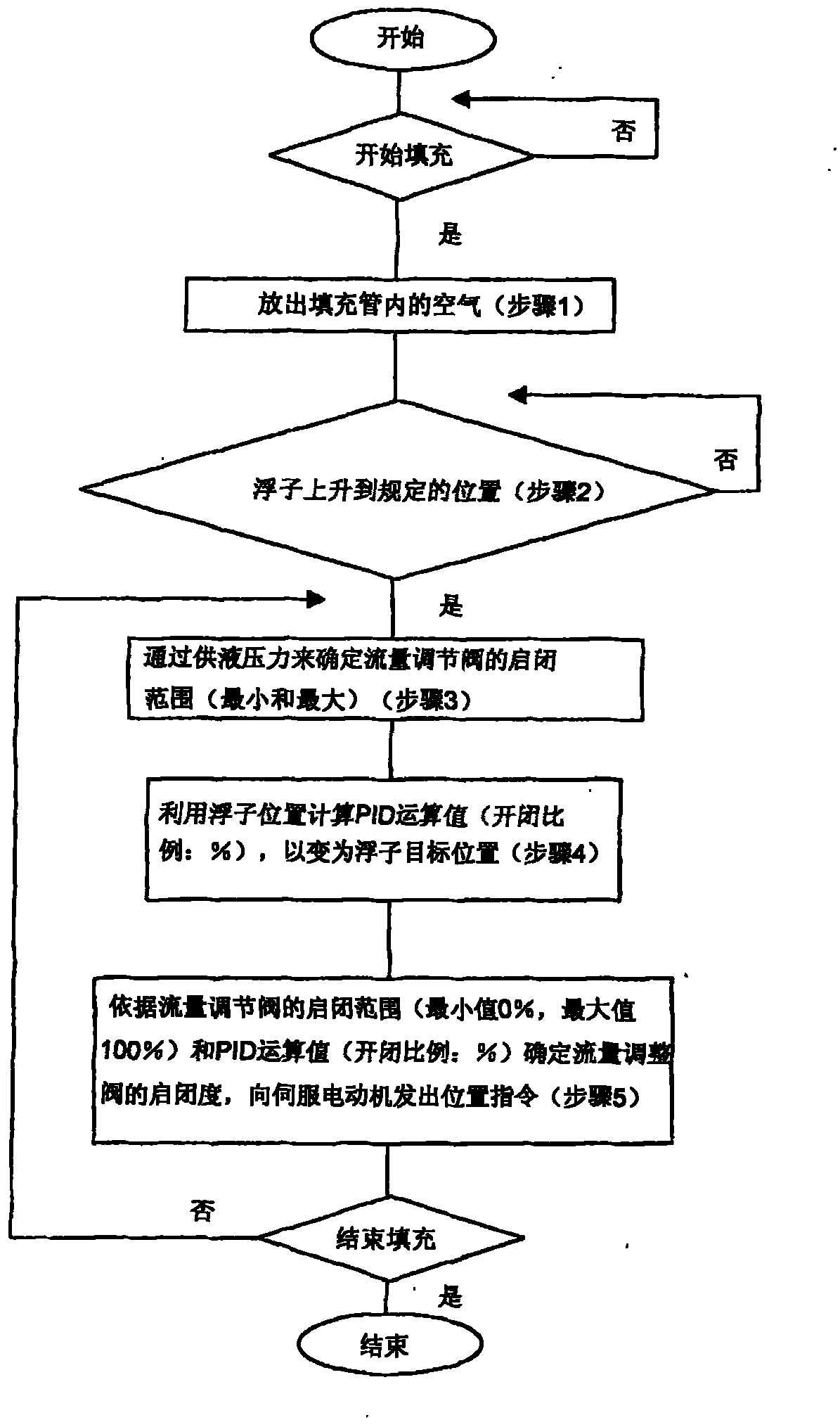

[0015] As the liquid filling and packaging device of the present invention, the following liquid filling and packaging device may be used, which seals both ends of the packaging material in the longitudinal direction to form a tube, fills the tube-shaped packaging material with a filling liquid, and fills the tube with the filling liquid. The tubular packaging material is conveyed downward by a length equivalent to approximately one container, while being sealed and packaged in a direction perpendicular to the longitudinal direction of the tubular packaging material, wherein the liquid filling and packaging device includes: a filling pipe of the flow regulating valve; a pressure sensor provided on the upstream side of the above flow regulating valve and detecting the pressure of filling liquid supplied from the filling liquid tank; a float having a magnet floating in the filling liquid filled in the tubular packaging material; A magnetic sensor that detects changes in the stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com