Abnormal jet detecting device of ink jet head and detecting method

An abnormality detection, inkjet head technology, applied in power transmission devices, printing, transfer materials, etc., can solve the problems of longer reset time, more use of orientation film materials, complicated control, etc., and achieves a narrower nozzle spacing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

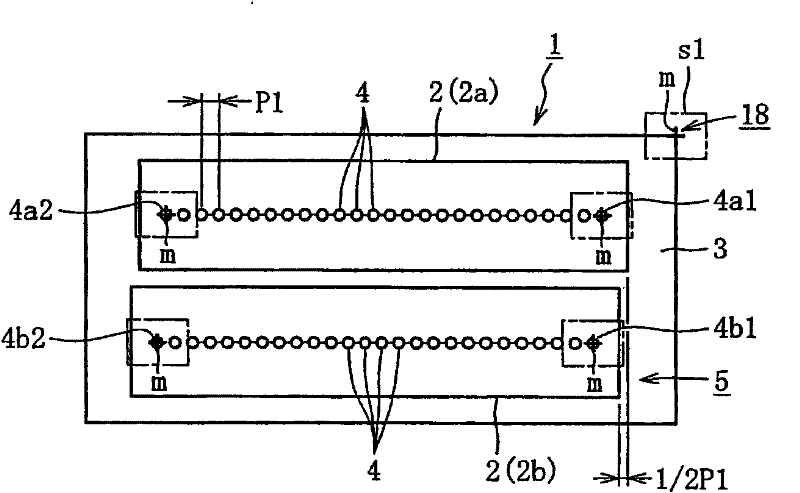

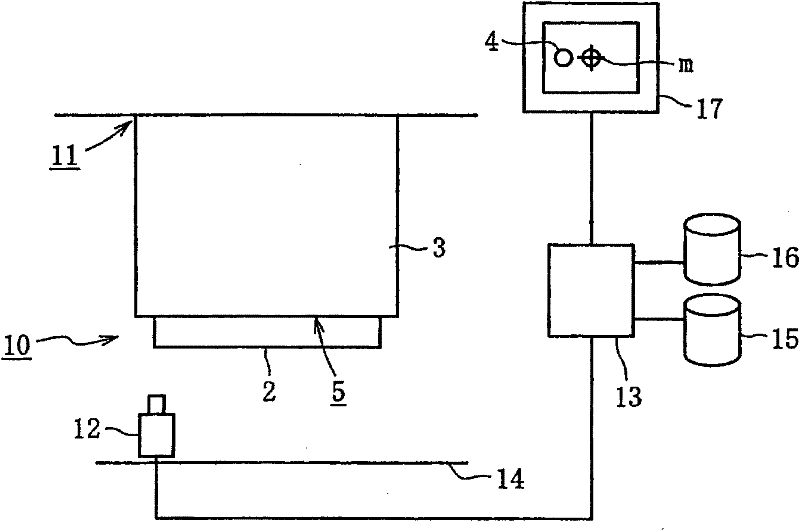

[0101] Figure 1 to Figure 6 The first embodiment of the present invention will be illustrated. The inkjet head 1 described in the first embodiment, such as figure 1 As shown, it consists of two linear inkjet nozzles 2a, 2b and a housing 3 for installing the linear inkjet nozzles 2a, 2b.

[0102] The linear inkjet nozzles 2a and 2b are arranged in a row at predetermined intervals, and the nozzles 4 which discharge the liquid material are arranged in a row. Since the linear inkjet nozzles 2a and 2b mold the nozzles 4 simultaneously during molding, the shape and position of each nozzle 4 can be manufactured with high precision. In addition, the linear inkjet nozzles 2a and 2b supply liquid material to each nozzle 4 from respective liquid material supply parts (not shown), and based on an ejection command signal from a control device (not shown), at a predetermined timing Spray liquid material. Thereby, the linear inkjet nozzles 2a and 2b can discharge the liquid material fr...

no. 2 approach

[0154] Figure 7 to Figure 11 The second embodiment of the present invention will be illustrated. The ejection abnormality detecting device 1 of the inkjet head described in the second embodiment is, for example, Figure 7 and Figure 8 As shown in (a), by the camera 5 that photographs the liquid material 4 ejected from the nozzle 3 of the inkjet head 2; the light source 6 that irradiates the light required for photographing; processing the image photographed by the camera 5, thereby detecting ejection abnormalities The ejection abnormality detection part 7 is constituted. Furthermore, in this embodiment, as Figure 7 As shown, the inkjet head 2 has a structure in which a single inkjet head 2a in which the nozzles 3 are arranged in series is arranged in a zigzag manner in a longitudinal direction with different positions shifted from each other.

[0155] Camera 5 such as Figure 7 As shown, from the direction perpendicular to the ejection direction of the inkjet head 2, t...

no. 3 approach

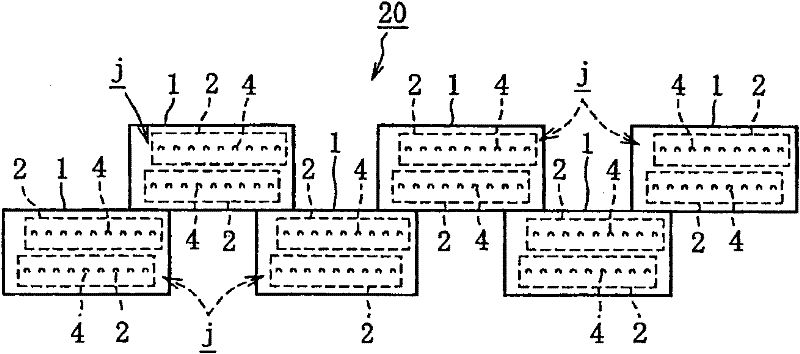

[0182] Figure 13 ~ Figure 17 The third embodiment of the present invention will be illustrated. The film forming apparatus according to the third embodiment, such as Figure 13 As shown, an inkjet head 10 , a film thickness setting unit 20 , a film thickness data storage unit 30 , a gradation profile generation unit 40 , and a film forming unit 50 are provided.

[0183] In this embodiment, the inkjet head 10 is formed by forming line type inkjet nozzles 12 arranged in a row with nozzles 11 for ejecting liquid materials so that the positions of the nozzles 11 are shifted from each other by half the pitch 1 / 2Pn of the nozzle pitch Pn. One inkjet nozzle unit 13 arranged side by side in a parallel manner, and in a staggered manner along the direction of the nozzle 11 provided with the linear inkjet nozzle 12, the positions are staggered differently from each other, and the inkjet nozzle unit 13 is arranged in series. .

[0184] In this inkjet head 10 , line type inkjet nozzles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com