Ultrasonic punching machine

A punching machine and ultrasonic technology, applied in the field of ultrasonic processing equipment, can solve problems such as impact point cracks, thin material edge and corner cracks, etc., and achieve the effects of reducing fragmentation rate, improving surface finish, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

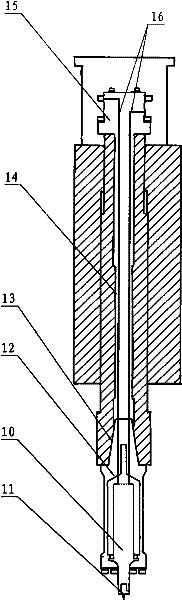

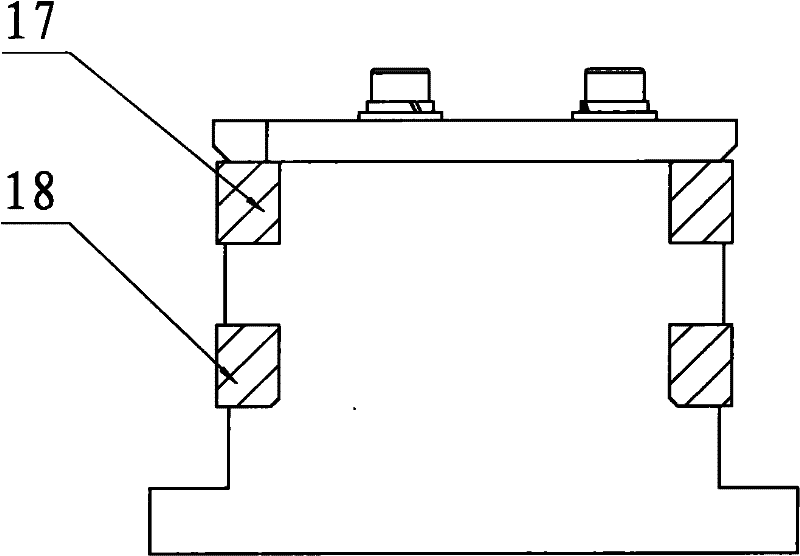

[0012] The ultrasonic drilling machine includes a CNC milling machine 1, a CNC milling machine controller 2, a CNC milling machine spindle rotation component 3, a vision system component 4, an industrial control machine 5, a CNC milling machine table 6, a stabilized power supply 8 and an ultrasonic power supply 9, the The main shaft in the spindle rotation assembly 3 of the CNC milling machine is provided with a main shaft through hole 14 along the axis, and a collector ring assembly 15 is fixedly arranged on the top of the main shaft through hole 14, and is fixed in the tapered interface 13 at the bottom end of the main shaft through hole 14. The fixed sleeve 12 of the piezoelectric ceramic transducer is provided, and the piezoelectric ceramic transducer 10 is arranged in the fixed sleeve 12 of the piezoelectric ceramic transducer, and the lower end of the piezoelectric ceramic transducer 10 is fixedly connected with the drill bit 11. Together, the upper end of the piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com