Forging process and tool of dynamometer annulus

A dynamometer and instrument ring body technology, which is applied to the forging process of the dynamometer ring body and its tooling field, can solve problems such as poor force conditions, long processing hours, and inconsistent force directions, so as to ensure work accuracy and Long-term stability, good stress conditions, and the effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

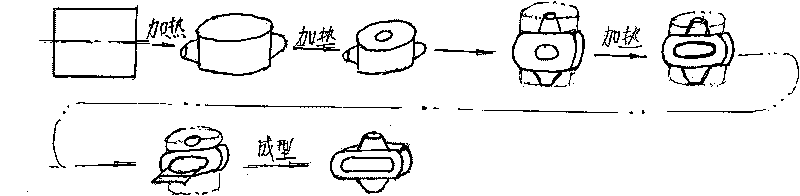

[0023] The forging of the dynamometer ring body is carried out on general forging equipment and is carried out by free forging method. The specific process flow is as follows:

[0024] 1. Cut out a section of forged steel bar for forging blanks, and block materials can also be used;

[0025] 2. Heating Put the cut billets in an electric furnace for heating. The furnace temperature is 500°C when the furnace is installed, heat at a low speed at a slow speed, heat up to 800-850°C, keep the temperature for 10-15 minutes, and then quickly heat up to a high speed. The initial forging temperature of the steel is kept for 7-10 minutes to reduce the structural stress generated during the heating process and the temperature stress caused by the temperature difference between the inside and outside of the billet, prevent forging cracks, and then release for forging;

[0026] 3. Forging the flat square: Lengthen the heated blank along the axis of the round blank, forge it into a flat squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com