Floatation separation process for galenite and chalcopyrite

A technology of galena and chalcopyrite, applied in flotation, solid separation, etc., can solve problems such as environmental pollution, high toxicity of dichromate, difficult to handle chromium ions, etc., and achieve low production cost and no pollution in the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

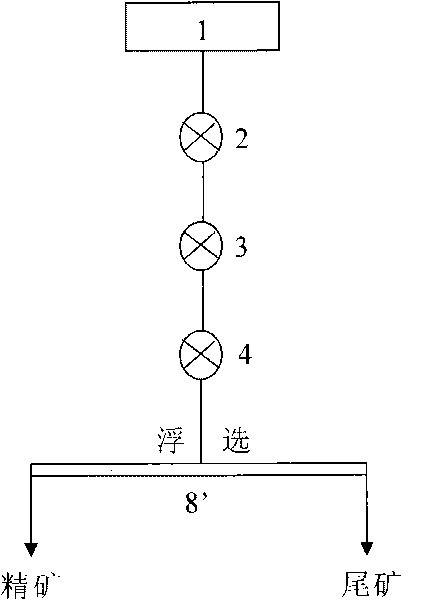

Method used

Image

Examples

Embodiment 1

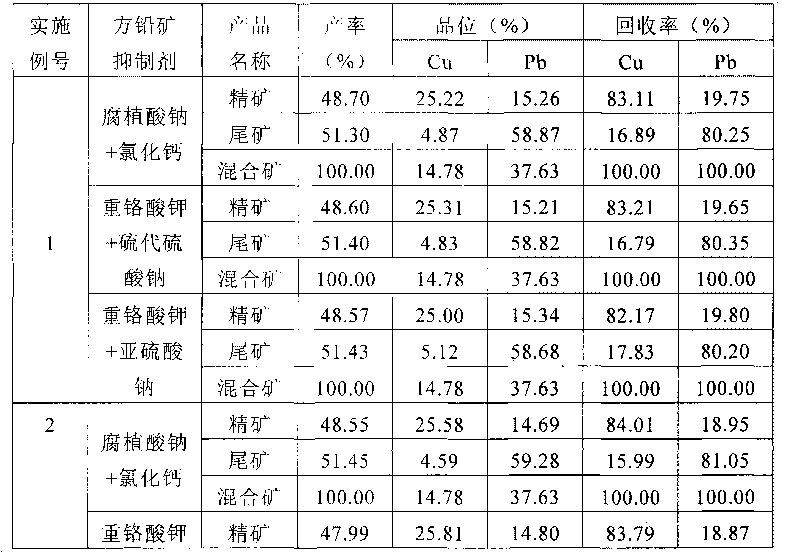

[0016] Grind galena and chalcopyrite to -0.074mm and then mix them by equal weight. Use sodium humate and calcium chloride to mix and stir for 5 minutes. The dosage of sodium humate is 160mg / L, and the dosage of calcium chloride is 8× 10 -4 mol / L, the collector is sodium butyl xanthate, and the concentration of the collector is 1×10 -4 mol / L, stirring for 2 minutes, adding foaming agent is butyl ether alcohol, the dosage is suitable to produce uniform foam, stirring time is 2 minutes, flotation for 8 minutes. The results of flotation separation are shown in Table 1. For the convenience of comparing the separation results, Table 1 also shows the flotation separation results of potassium dichromate+sodium thiosulfate and potassium dichromate+sodium sulfite to suppress lead and float copper.

Embodiment 2

[0018] Grind galena and chalcopyrite to -0.074mm and then mix them by equal weight. Use sodium humate and calcium chloride to mix and stir for 5 minutes. The dosage of sodium humate is 160mg / L, and the dosage of calcium chloride is 8× 10 -4 mol / L, the collector is O-isopropyl-N-ethylthiocarbamate, and the concentration of the collector is 1.7×10 -4 mol / L, stirring for 2 minutes, flotation for 8 minutes. The results of flotation separation are shown in Table 1. In order to compare the separation results, the flotation separation results of potassium dichromate + sodium thiosulfate and potassium dichromate + sodium sulfite to suppress lead and float copper are also given.

[0019] Table 1 Galena and chalcopyrite flotation separation results

[0020]

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com