Energy-saving electric heating cooker

A technology of electric heating pan and heating device, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc. It can solve the problems of long single cooking time, potential safety hazards, and easy energy dissipation of hot air, so as to increase the effective The area of radiation and absorption, the effect of enhancing the effect of directional radiation heating, and enhancing the effect of infrared heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

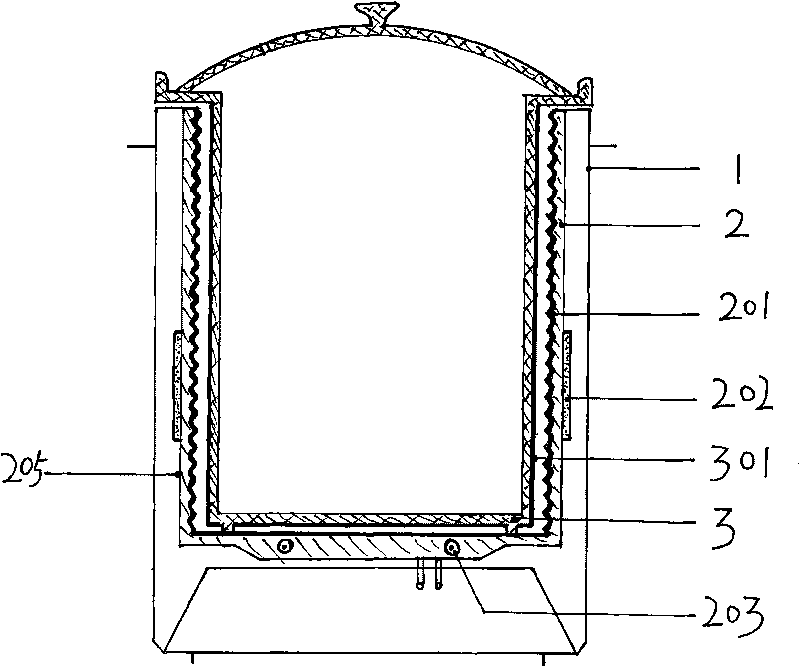

[0042] Such as figure 1 As shown, the energy-saving electric heating pot of the present embodiment, its side includes casing 1, barrel-shaped heating device 2, the liner 3 that non-metallic materials such as purple sand, pottery, ore, glass make successively from outside to inside, and it also Contains electrical controls. Wherein, the heating device 2 includes a barrel-shaped heat conductor such as aluminum, copper, iron, a tubular electric heating element 203 embedded in the bottom of the heat conductor, and a strip-shaped electric heating element 202 fixed on the outer side of the heat conductor; the inner surface of the heating device 2 is covered with Infrared radiating material layer 201, and its side part is threaded surface, and bottom is smooth surface; The outer surface of heating device 2 is infrared ray reflective surface 205, can keep smooth and clean surface, surface polishing, set zinc layer, titanium layer and other technologies. accomplish. The outer surface...

no. 2 example

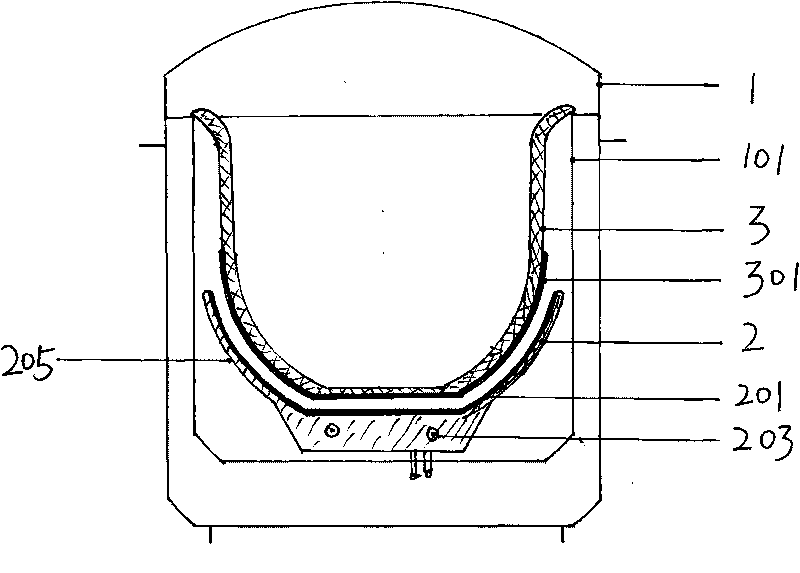

[0052] Such as figure 2 As shown, the energy-saving electric heating pot of the present embodiment includes a housing 1, a heat insulating layer 101 within the housing 1, and an inner shell made of non-metallic materials such as purple sand, pottery, ore, and glass within the heat insulating layer 101. Liner 3, a disk-shaped heating device 2 located at the bottom of the inner liner 3 and opposite to the outer surface of the lower part, and an electric control device. Wherein, the heating device 2 includes a tubular electric heating element 203 embedded in the bottom body, and the inner surface is covered with an infrared radiation material layer 201 , while the outer surface is an infrared reflective surface 205 . The bottom part of the outer surface of the inner container 3 opposite to the inner surface of the heating device 2 is covered with an infrared absorbing material layer 301 and is not in contact with the heating device 2 at all.

[0053] The outer surface of the he...

no. 3 example

[0056] Such as image 3 As shown, the energy-saving electric heating pot of the present embodiment includes a housing 1, a heat insulating layer 101 within the housing 1, and an inner shell made of non-metallic materials such as purple sand, pottery, ore, and glass within the heat insulating layer 101. Liner 3, the disk-shaped heating device 2 covering the lower part of the inner tank 3, the electric control device, and the suspension device 204 supporting the heating device 2. Wherein, the heating device 2 includes a tubular electric heating element 203 embedded in the bottom body, and a temperature-sensing probe 4 of an electric control device is arranged at the center of the bottom. The inner surface of the heating device 2 is covered with an infrared radiation material layer 201 , while the outer surface is an infrared reflective surface 205 . The lower outer surface of the liner 3 is covered with an infrared absorbing material layer 301 . The bottom of the inner surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com