Optical fiber fusion splicer

An optical fiber fusion splicer and optical fiber connection technology, which is applied in the direction of optics, light guides, optical components, etc., can solve the problems of a lot of time required for work, increased manufacturing costs of fusion splicers, foreign matter on the screen, etc., to prevent external damage and/or damage , Reduce manufacturing costs, reduce the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

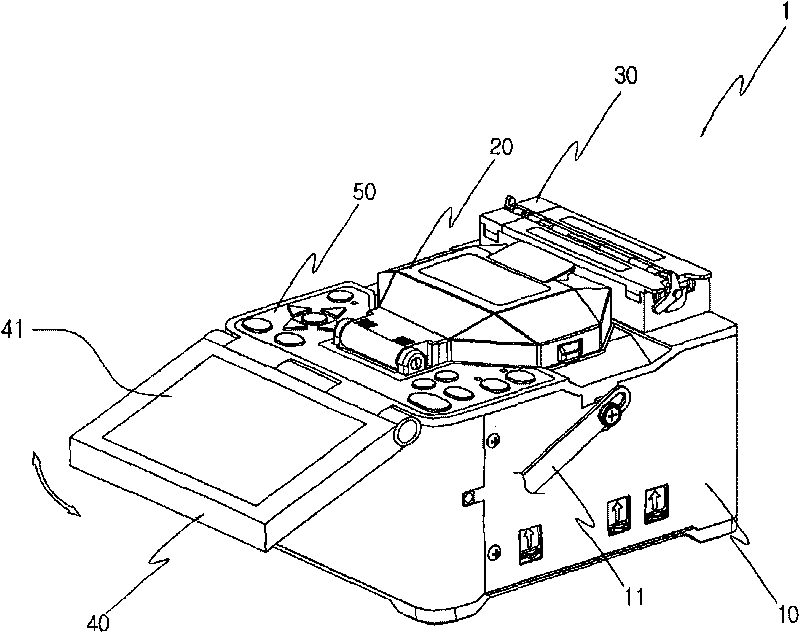

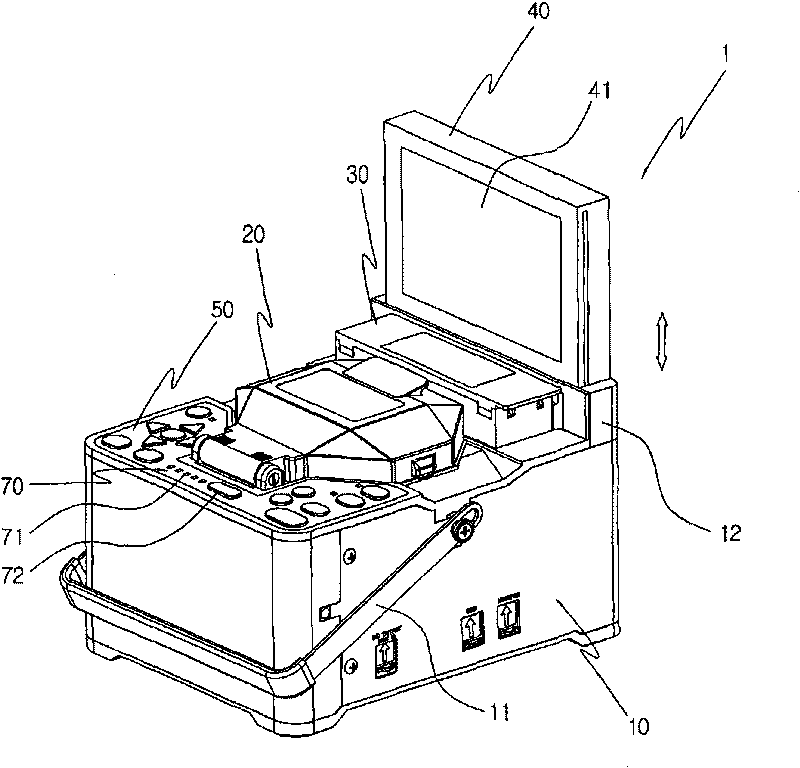

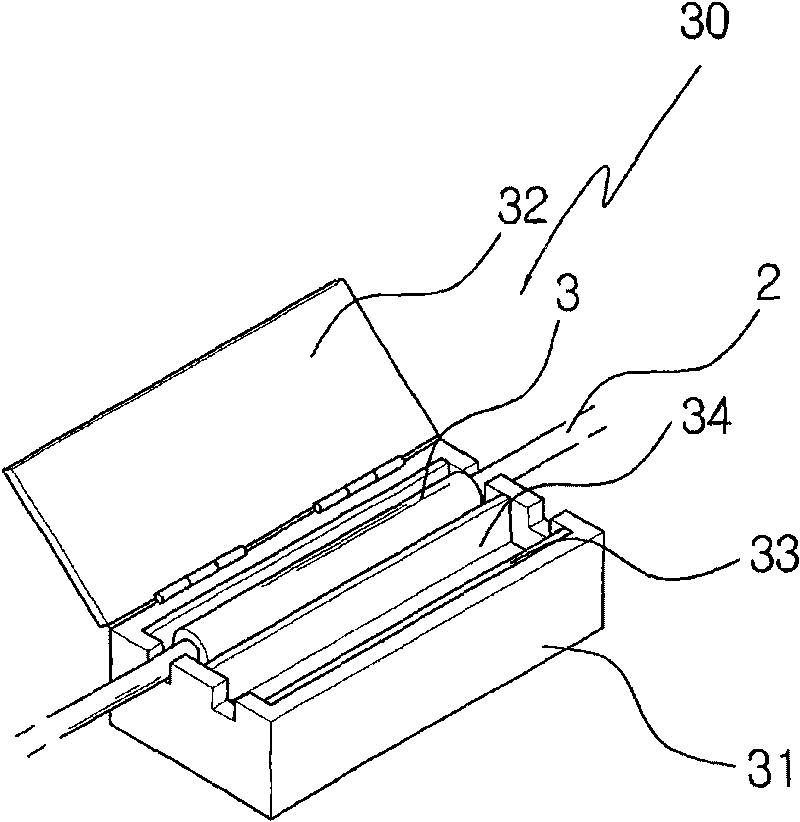

[0042] Hereinafter, an optical fiber fusion splicer according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0043] Such as figure 2 As shown, the fusion splicer (1) according to this embodiment includes a main body (10), a connecting part (20), a heating part (30), a monitor (40), an operating part (50), a fixing part (60) and a battery A remaining power display unit (70).

[0044] The main body (10) is used to install other components, and a handle (11) is provided at a predetermined position on the left side for easy movement of the connecting machine (1).

[0045] The connecting part (20) is used to connect the ends of two optical fibers, and is arranged on the upper surface of the main body (10).

[0046] The connection part (20), although not shown, is composed of a fixed cover for fixing the optical fiber, an electrode rod for fusing the optical fiber, an objective lens, an illuminating la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com