Short magnetic circuit structural cylindrical DC linear electric motor

A linear motor and short magnetic circuit technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, electrical components, etc., can solve the problem of poor dynamic characteristics of motors, low air gap magnetic density, and iron core consumption Many problems, to achieve the effect of increasing the air gap magnetic flux density, reducing the secondary quality and magnetic flux leakage, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

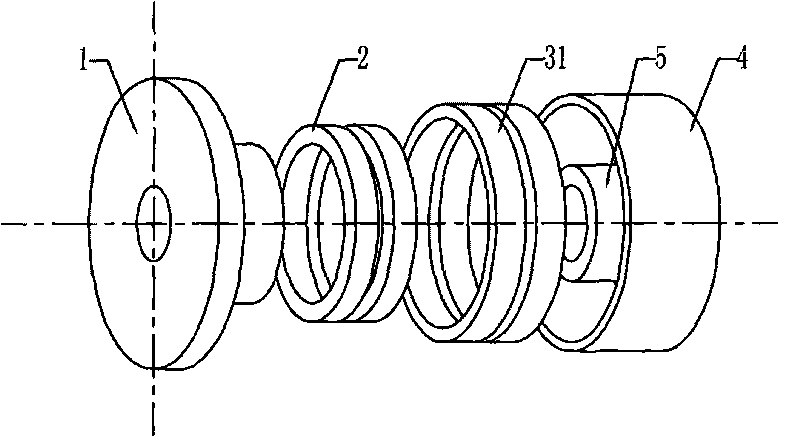

[0008] Specific implementation mode one: combine figure 1 , figure 2 , Figure 23 and Figure 24 Describe this embodiment, this embodiment is made up of primary, secondary and air gap;

[0009] The primary includes a winding support base 1 and an armature winding 2; the armature winding 2 is a single-phase winding, and the single-phase winding is composed of two coils, the two coils are connected in series, and the winding direction is opposite; the two coils Axially fixed on the winding support base 1; the secondary includes a permanent magnet and a magnetic yoke; the magnetic yoke includes an outer magnetic yoke 4 and an inner magnetic yoke 5, and the outer magnetic yoke 4 and the inner magnetic yoke 5 are circular Annular magnetic conducting yoke; the permanent magnet includes an outer secondary permanent magnet 31, and the outer secondary permanent magnet 31 is three annular permanent magnets; the three annular permanent magnets of the outer secondary permanent magnet...

specific Embodiment approach 2

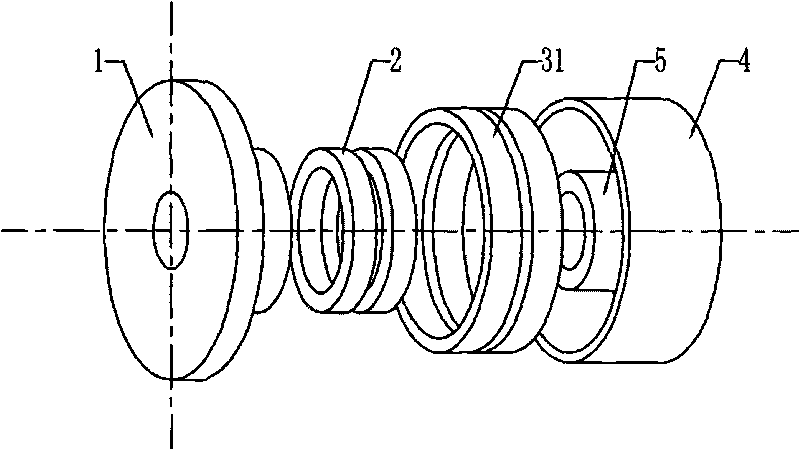

[0010] Specific implementation mode two: combination figure 2 , Figure 4 , Figure 6 , Figure 8 , Figure 10 , Figure 12 , Figure 14 , Figure 16 , Figure 25 and Figure 26 This embodiment is described. The difference between this embodiment and the specific embodiment is that the two coils of the armature winding 2 are axially fixed on the outer wall of the boss of the winding support seat 1 or fixed on the end surface of the boss by using an insulating material. . Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

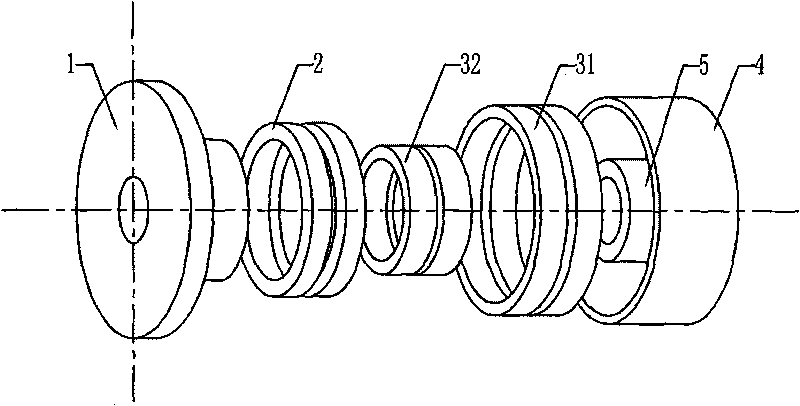

[0011] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the permanent magnet also includes an inner secondary permanent magnet 32, and the inner secondary permanent magnet 32 is three annular permanent magnets, and the inner secondary permanent magnet 32 Closely fit on the outer wall of the circular inner magnetic yoke 5; the axial length of the inner secondary permanent magnet 32 is the same as the axial length of the outer secondary permanent magnet 31, and the inner secondary permanent magnet 32 is sequentially along the axial direction Radial magnetization, axial magnetization, radial magnetization; the magnetization direction of the radially magnetized permanent magnet in the inner secondary permanent magnet 32 is the same as that of the radially magnetized permanent magnet in the outer secondary permanent magnet 31, The magnetization directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com