Developing method and developing apparatus

A developing method and technology for developing equipment, which are applied to equipment, instruments, optics and other directions of an electrical recording process applying charge patterns, can solve the problem of reducing yield, contaminating laser sources and photodetectors, and cutting off monitoring signal parts that are time-consuming. problem, to achieve the effect of improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

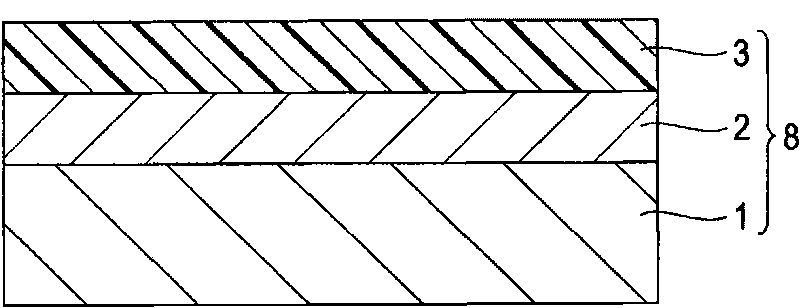

[0052] Figure 5A is the first embodiment of the present invention for the development step (such as Figure 2D and 2E Schematic side view of the developing device in ). Figure 5B is a schematic plan view of the developing device. In this first embodiment, the resist substrate 8 to be developed has a latent image constituted by the exposed portion 3a, and the track pitch of BD is 0.32 μm.

[0053] like Figure 5A and 5B As shown, the developing device 15 of the first embodiment includes a rotatable turntable 10 and a nozzle 12 for supplying a developer 13 . The developing device 15 also includes a laser light source 11 for emitting laser light L for monitoring, and zero-order light (reflected light) L for detecting reflected laser light L. 0 The amount of light the first sensor R 0 and primary light (diffracted light) L for detecting reflected laser light L 1 The second sensor R of the amount of light 1 .

[0054] The turntable 10 is coupled to the rotation shaft 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com