High-sensitivity digital nanovoltmeter and realization method thereof

A high-sensitivity, digital technology, applied in the direction of measurement using digital measurement technology, can solve the problems of not being able to replace the photoelectric amplifying galvanometer, failing to meet high-precision measurement requirements, low anti-common-mode interference ability, etc., to achieve stable readings , low noise floor, simple analog circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in conjunction with the accompanying drawings.

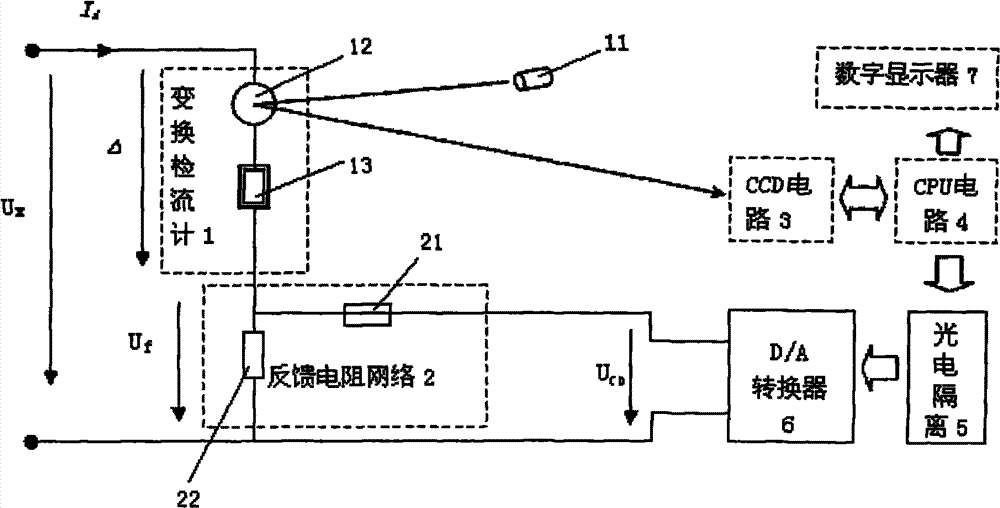

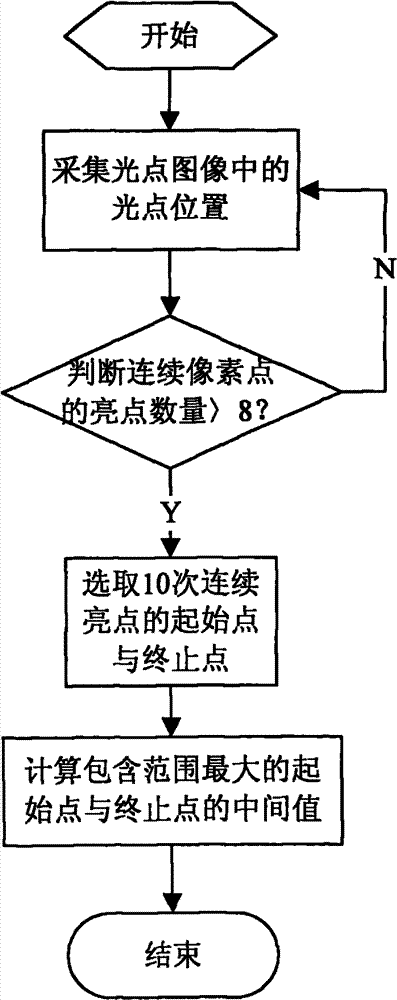

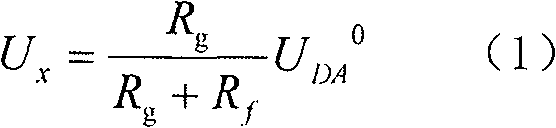

[0025] Such as figure 1 As shown, the high-sensitivity digital nanovoltmeter of the present invention includes a conversion galvanometer 1, a feedback resistor network 2, a CCD circuit 3, a CPU circuit 4, a photoelectric isolation 5, a D / A converter 6 and a digital display 7. Among them, the conversion galvanometer 1 and the feedback resistor network 2 are connected in series to form a measurement circuit, and the two ends of the measurement circuit are connected to the measured voltage U x , the current in the measurement loop is I x . The conversion galvanometer 1 mainly includes a light-emitting element 11, a mirror 12 and a coil 13, and the current I x The reflector 12 is driven to deflect at a certain angle, and the light beam emitted by the light emitting element 11 is reflected by the reflector 12 to form an image on the CCD circuit 3 . The CPU circuit 4 reads the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com