System for cooling vertical furnace and utilizing residual heat

A waste heat and shaft furnace technology, applied in the fields of pellet sintering, annular shaft furnace cooling and waste heat utilization, can solve the problem of low heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

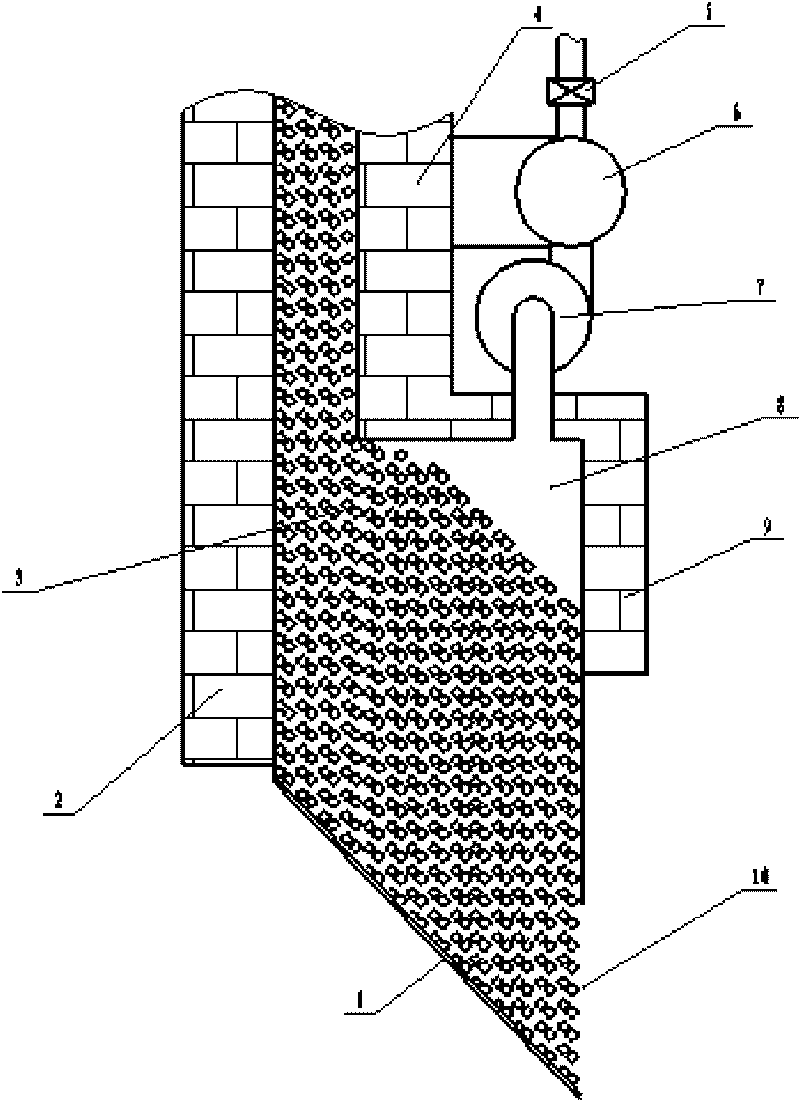

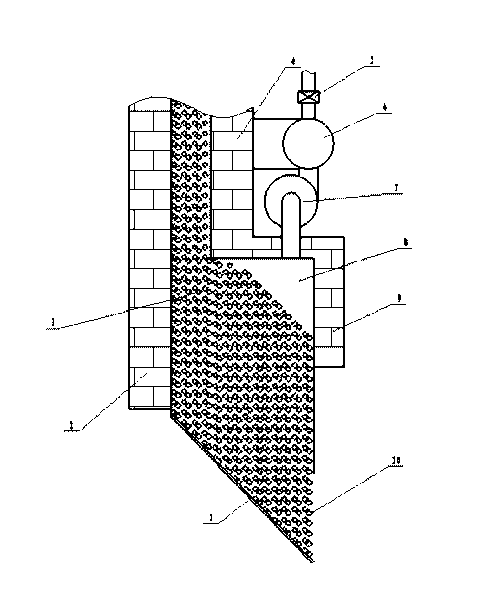

[0005] Specific embodiment one: typical structure of the present invention. figure 1 Among them, 2 is the inner masonry of the shaft furnace cooling zone, and 4 is the outer masonry. In order to facilitate air induction and heat exchange, the diameter of the outer masonry at the lower part of the cooling zone is enlarged, and 9 is the enlarged masonry. The enlarged cooling zone can reduce air circulation resistance and increase heat exchange area. 3 is a cooling zone. The first is the air grate, which allows outside air to enter the cooling zone, and at the same time controls the direction of the pellets and the cross-sectional shape of the cooling zone to obtain the best cooling effect and combustion air temperature. The 7th, combustion-supporting blower fan. 6 is a pipeline type air distribution bag. 8 is the air-inducing cavity. 6 and 8 all play the effect of equalizing wind pressure. Under the suction of the combustion-supporting fan 7, the external air enters the co...

specific Embodiment 2

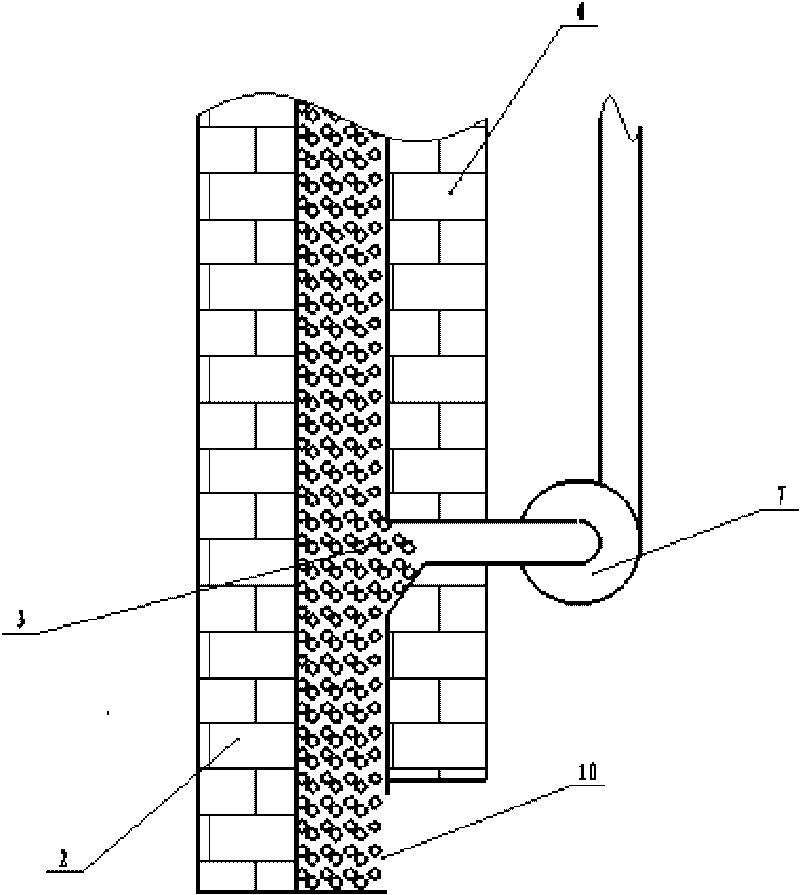

[0006] Specific embodiment two: the concise structure of the present invention. figure 2 In the process, under the suction of the combustion-supporting fan 7, the external air enters the cooling zone 3 through the discharge port 10, heats up while cooling the pellets, and enters the burner through the combustion-supporting fan 7. The flow rate of the fan can be adjusted to control the size of the combustion air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com