Composite heat sink of electrical circuit

A heat sink and electrical technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems such as thermal conductivity limitations of insulating layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

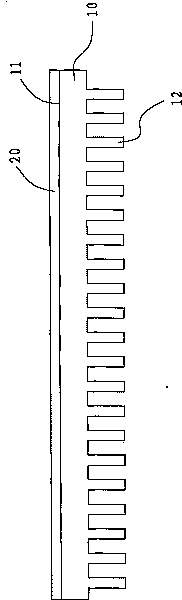

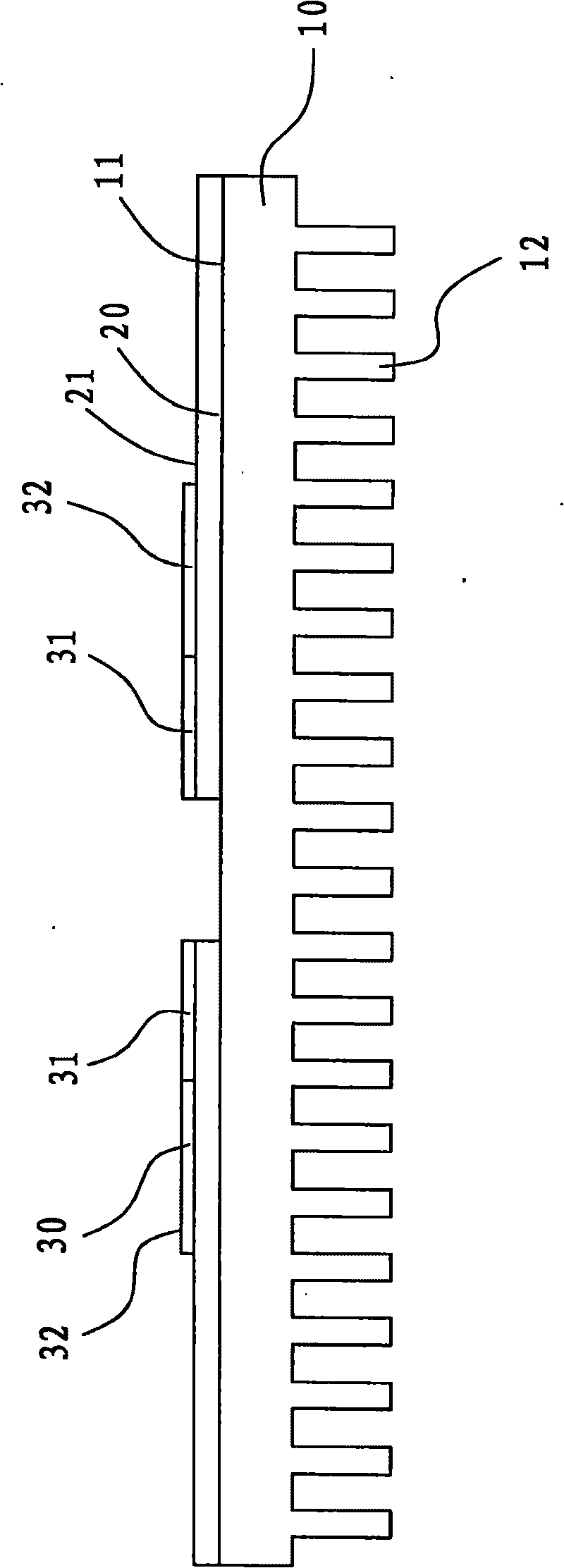

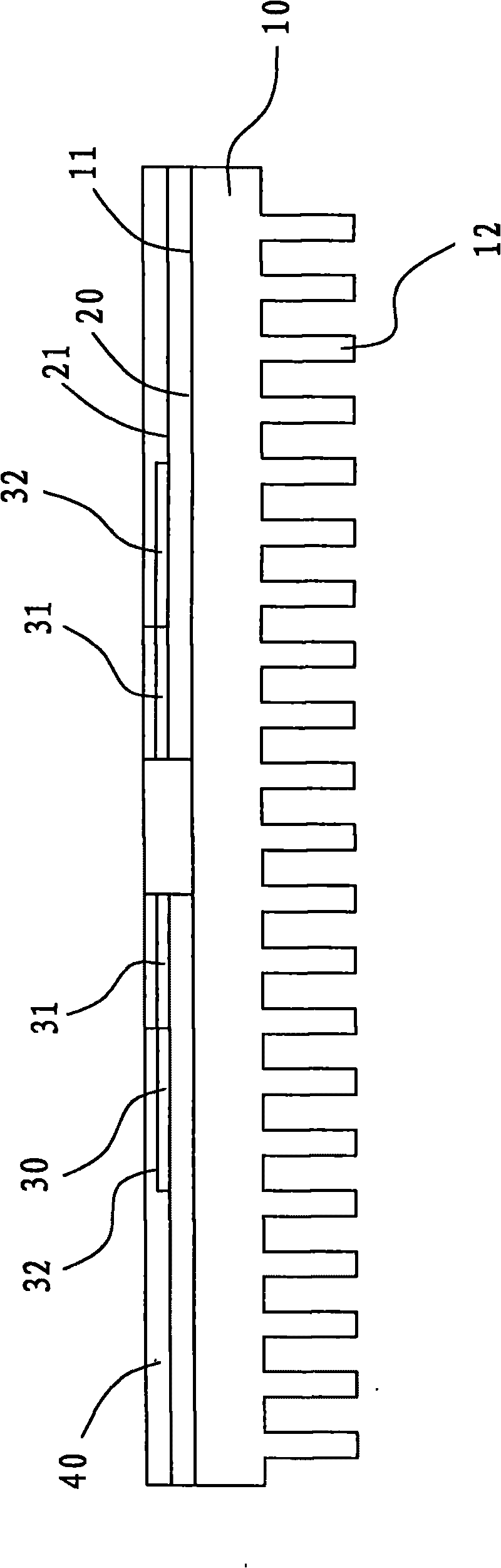

[0042] see Figure 1 to Figure 7 As shown, the planar structure, the three-dimensional structure and the schematic diagram of the implementation of the composite radiator of the electrical circuit provided by the present invention can reach the composite radiator of the electrical circuit of the present invention, and the composite radiator of the electrical circuit includes:

[0043] A heat sink 10, the heat sink 10 is provided with cooling fins 12 or heat dissipation materials such as metal plates, ceramic plates, graphite plates, etc., through the setting of the heat sink 10, the heat energy generated by the electrical and electronic components 50 can be effectively discharged , the other side surface 11 is provided with a thermally conductive insulating layer 20;

[0044] A thermally conductive insulating layer 20, the thermally conductive insulating layer 20 contains uniformly distributed thermally conductive powder, and is combined on the other side surface 11 of the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com