Coalbed methane high-power pulse fracturing developing device

A strong pulse, coalbed methane technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of difficult to form coalbed methane desorption environment and conditions, difficult to change, etc., to improve operability and practicality The effect of high energy efficiency, high total energy and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

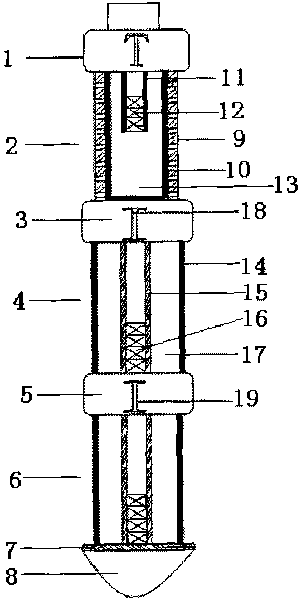

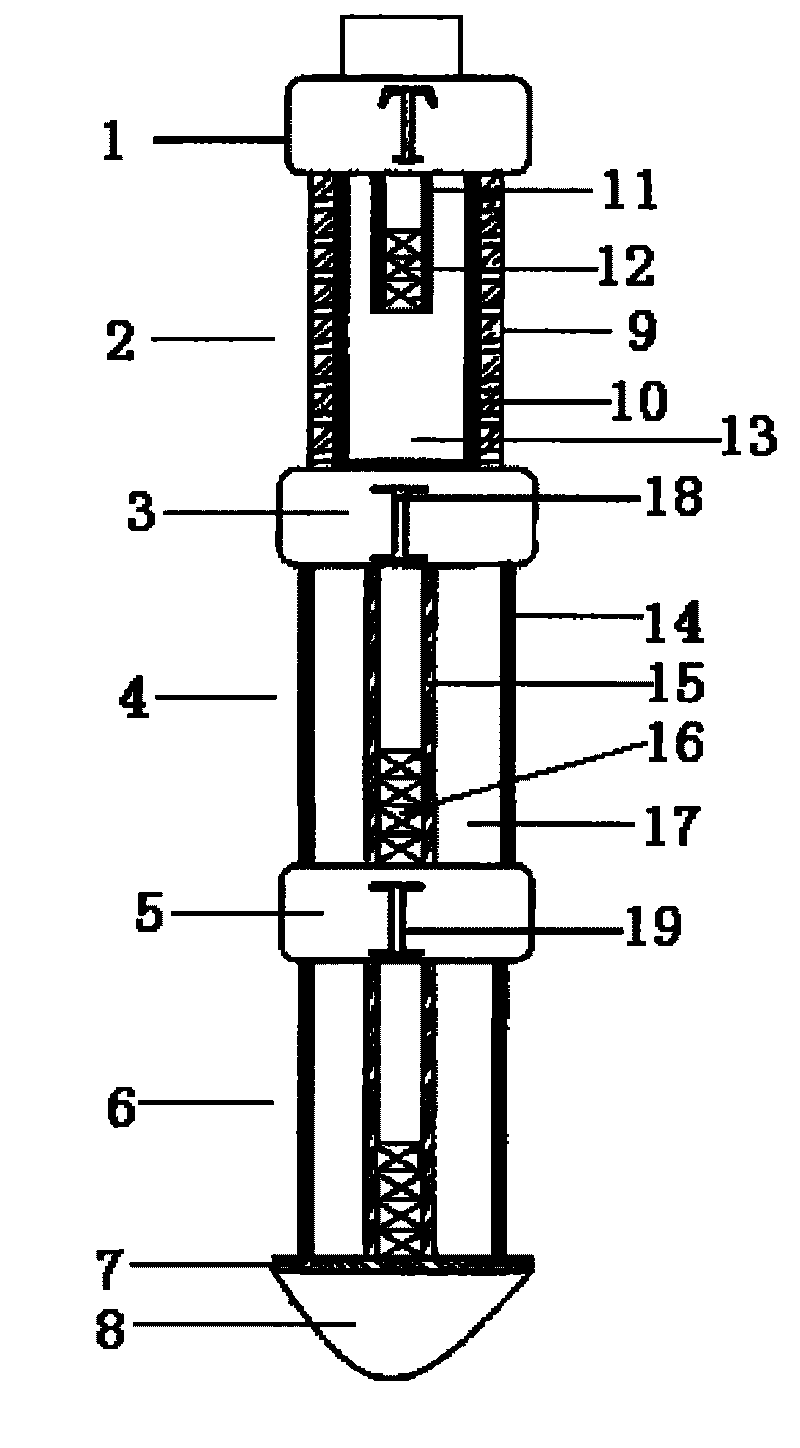

[0015] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] With reference to the accompanying drawings, a coalbed methane strong pulse fracturing development device includes a detonating device 1, which can use pressure detonation or impact detonation, and the detonating device 1 is connected with a high-pressure gas gun device 2, which passes through the first The conversion connector 3 is connected to the first load-bearing gas device 4, and the first load-bearing gas device 4 is connected to the second load-bearing gas device 6 through the second conversion connector 5. The end of the second load-bearing gas device 6 is a combustible guide body 8, a combustible baffle 7 is set between the second load-bearing gas device 6 and the combustible guide body 8.

[0017] Described high-pressure gas gun device 2 comprises a tubular pressure relief pipe 9, the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com