Outdoor bamboo floor and a method for manufacturing same

A technology of bamboo floor and manufacturing method, which is applied in the direction of manufacturing tools, paving surfaces paved with prefabricated blocks, roads, etc., can solve the problems of cracking, mildew, warping and deformation of bamboo floors, and can prolong the service life and prevent cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

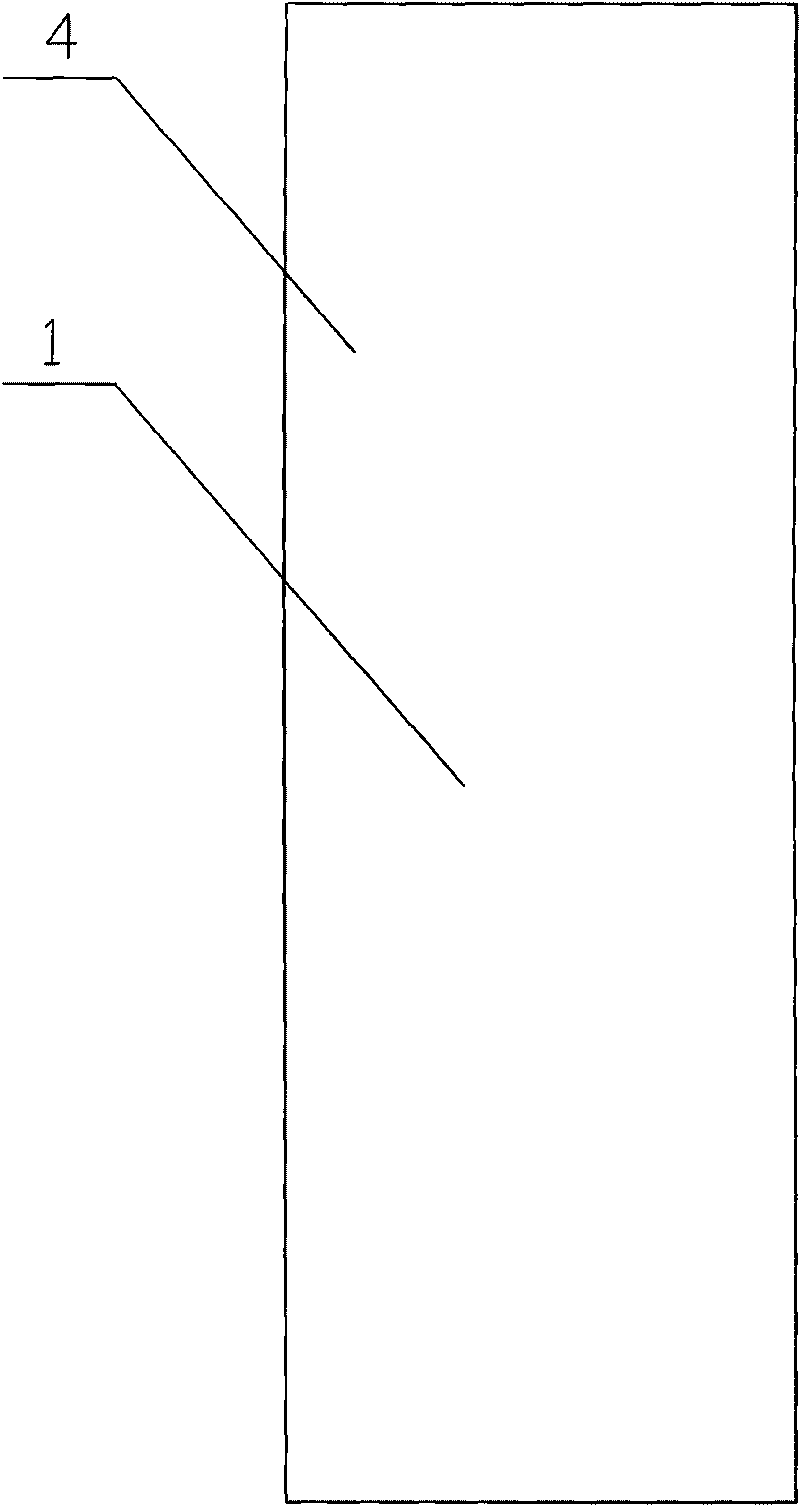

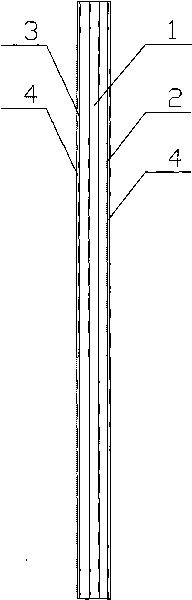

[0009] figure 1 , figure 2 The outdoor bamboo floor shown includes a bamboo floor body 1, the upper surface 2 of the bamboo floor body 1 is provided with a polyurethane thermosol coating 4, and the lower surface 3 of the bamboo floor body 1 is also provided with a polyurethane thermosol coating 4 .

[0010] During the specific operation, the polyurethane hot sol is heated to a liquid state, and sprayed on the upper surface 2 and the lower surface 3 of the bamboo floor body 1 through a spray gun.

[0011] During the specific operation, the polyurethane hot sol can also be heated to a liquid state, and the polyurethane hot sol can be sticked with a roller, and then rolled onto the upper surface 2 and the lower surface 3 of the bamboo floor body 1 .

[0012] During specific operations, the polyurethane hot sol can also be heated to a liquid state, sprayed on the upper surface 2 of the bamboo floor body 1 by a spray gun, stick the polyurethane hot sol with a roller, and then ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com