Method for manufacturing metal oxide nano-wire/noble metal nanocrystalline composite material

A noble metal nanocrystal and composite material technology is applied in the field of manufacturing metal oxide nanowires/precious metal nanocrystal composite materials, which can solve the problems of harsh conditions, difficulty in manufacturing composite materials, and difficulty in controlling the uniformity of noble metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

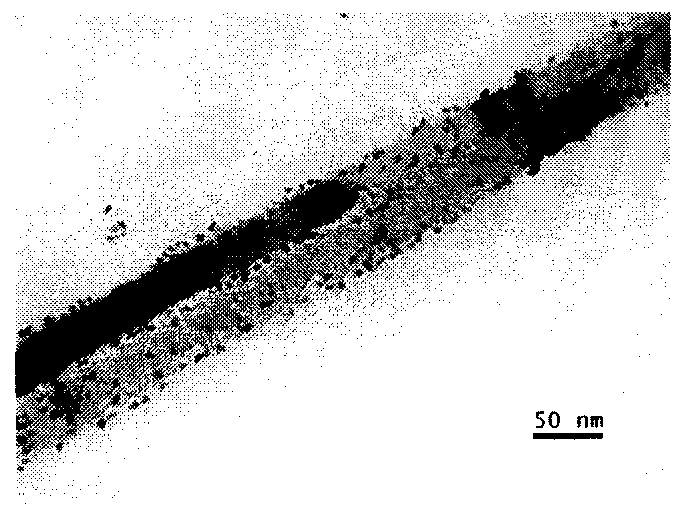

[0013] Example 1: Oxide nanowires are WO 3 Nanowires, noble metal nanocrystals are Au nanocrystals.

[0014] WO 3 For the preparation method of nanowires, please refer to the literature - Chemical Physics Letters, 2003, Vol.377, pp.317-321.

[0015] The preparation method of Au nanocrystals is as follows: 0.01 g of chloroauric acid (HAuCl 4 ·4H 2 O) Dissolve in 100 mL of deionized water, heat to boiling, add 2 mL of 1% trisodium citrate (Na 3 C 6 H 5 O 7 ·2H 2 O) aqueous solution; continue to heat and boil for 15min; after cooling to room temperature, restore to the original volume with distilled water. The obtained solution was centrifuged and washed with deionized water to obtain Au nanocrystals.

[0016] After ultrasonically dispersing 0.1 mg of Au nanocrystals in 5 mL of deionized water for 10-50 min, it was evenly added dropwise to 30 mL of 2-MEPA ethanol solution with a concentration of 1 mmol / L, stirred overnight for reaction, and centrifuged in a 3000 r / min hi...

Embodiment 2

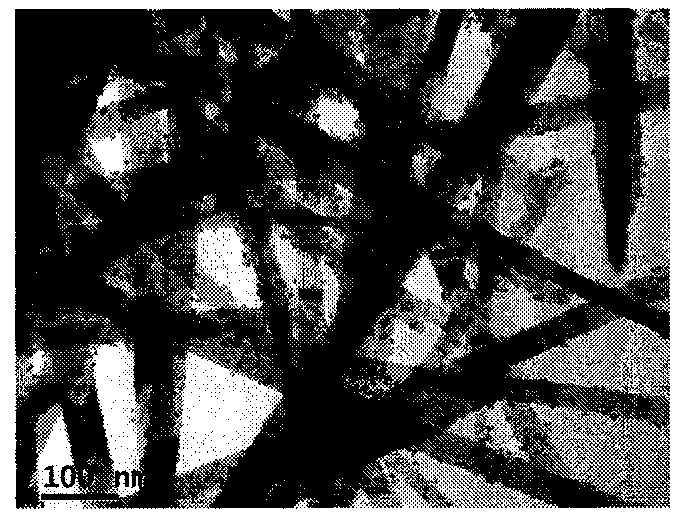

[0018] Example 2: The oxide nanowires are SnO 2 Nanowires, noble metal nanocrystals are Pt nanocrystals.

[0019] SnO 2 The preparation method of nanowires can be found in the literature - Nanotechnology, 2008, Vol.19, pp.185705 (8pp).

[0020] The preparation method of Pt nanocrystals is as follows: 0.08g of polyvinylpyrrolidone (PVP) is dissolved in 7mL of ethylene glycol (EG), then the above solution is transferred into a 50mL three-neck flask, the temperature is raised to 160°C, the temperature is maintained for 10min, and the solution is rapidly added to a 50mL three-neck flask. It adds 1mL 80mmol / L of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O), stop the reaction when the solution turns black. The obtained solution was centrifuged and washed with acetone to obtain Pt nanocrystals.

[0021] After ultrasonically dispersing 0.14 mg of Pt nanocrystals in 5 mL of ethanol for 10-50 min, it was evenly added dropwise to 30 mL of 2-MEPA ethanol solution with a concentration of...

Embodiment 3

[0023] Embodiment 3: The oxide nanowires are ZnO nanowires, and the noble metal nanocrystals are Pd nanocrystals.

[0024] For the preparation method of ZnO nanowires, please refer to the literature - Materials Chemistry and Physics, 2007, Vol.106, pp.58-62.

[0025] For the preparation method of Pd nanocrystals, please refer to the literature—Journal of the American Chemical Society, 2005, Vol.127, pp.7332-7333.

[0026] After ultrasonically dispersing 0.12mg Pd nanocrystals in 5mL of ethanol for 10-50min, it was evenly added dropwise to 30mL of 2-MEPA ethanol solution with a concentration of 1.5mmol / L, stirred overnight for reaction, and centrifuged in a 3000r / min high-speed centrifuge. , and washed with deionized water to prepare phosphoric acid-functionalized Pd nanocrystals.

[0027] The phosphoric acid-functionalized Pd nanocrystals were dispersed in 10 mL of ethanol, 60 mg of ZnO nanowires were added to it, after ultrasonic dispersion, the reaction was stirred overnigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com