Full-automatic dry powder press floating-type core rod cylinder device

A cylinder device, fully automatic technology, used in presses, material forming presses, manufacturing tools, etc., can solve the problems of restricting special-shaped parts, floating core rod stroke and surface position can not be adjusted arbitrarily, etc. Mold force, easy adjustment, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

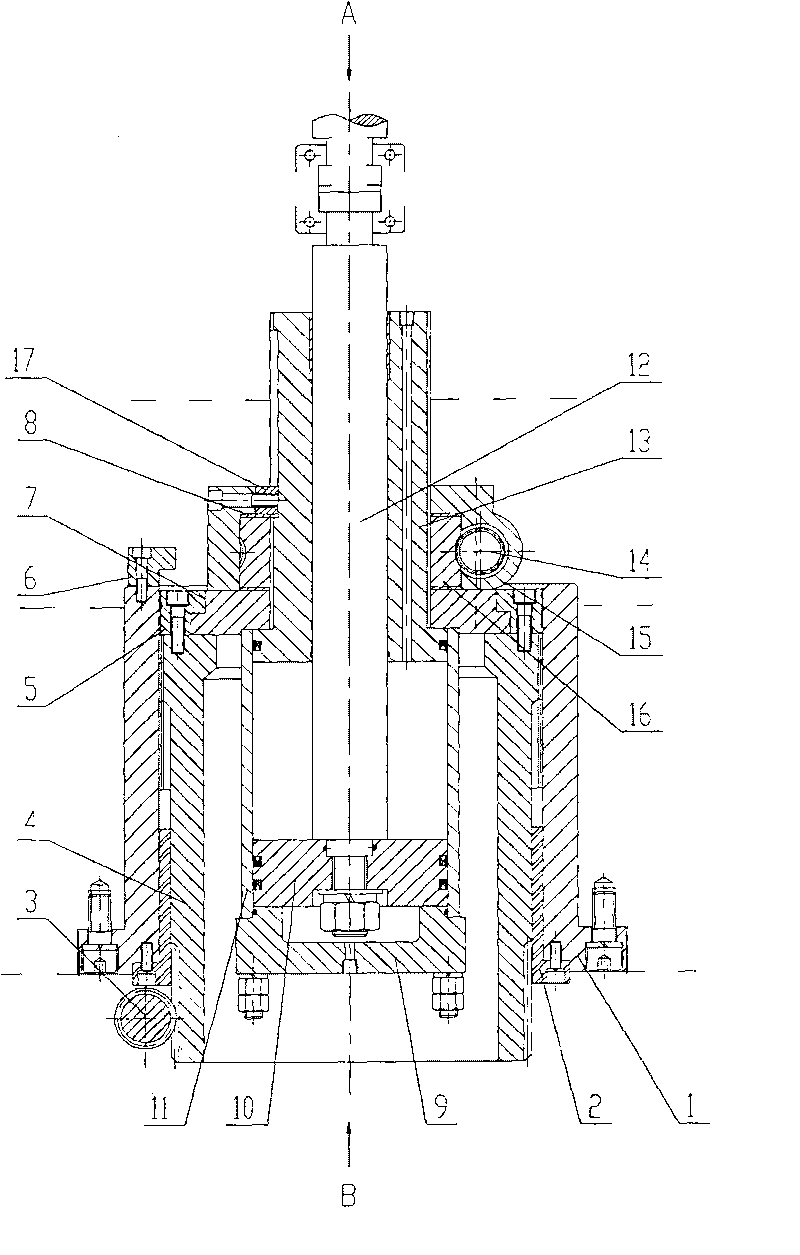

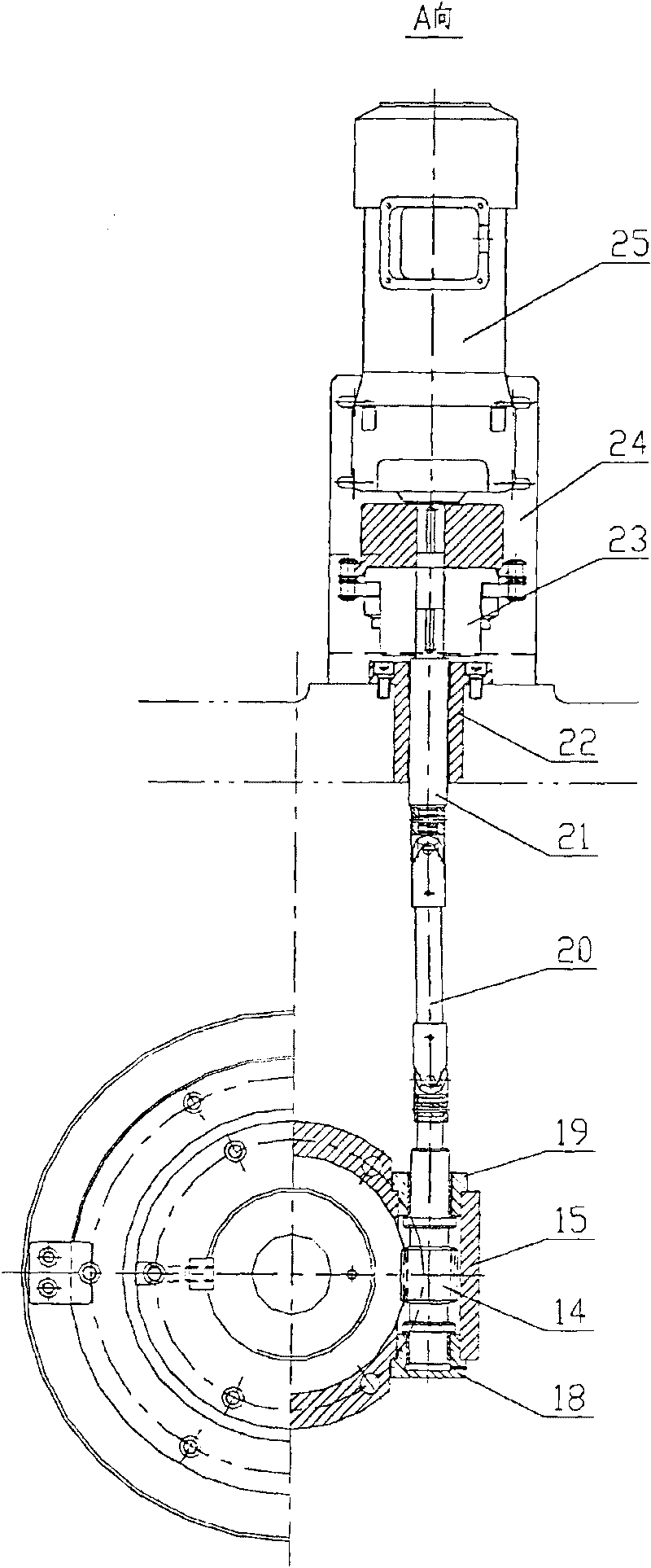

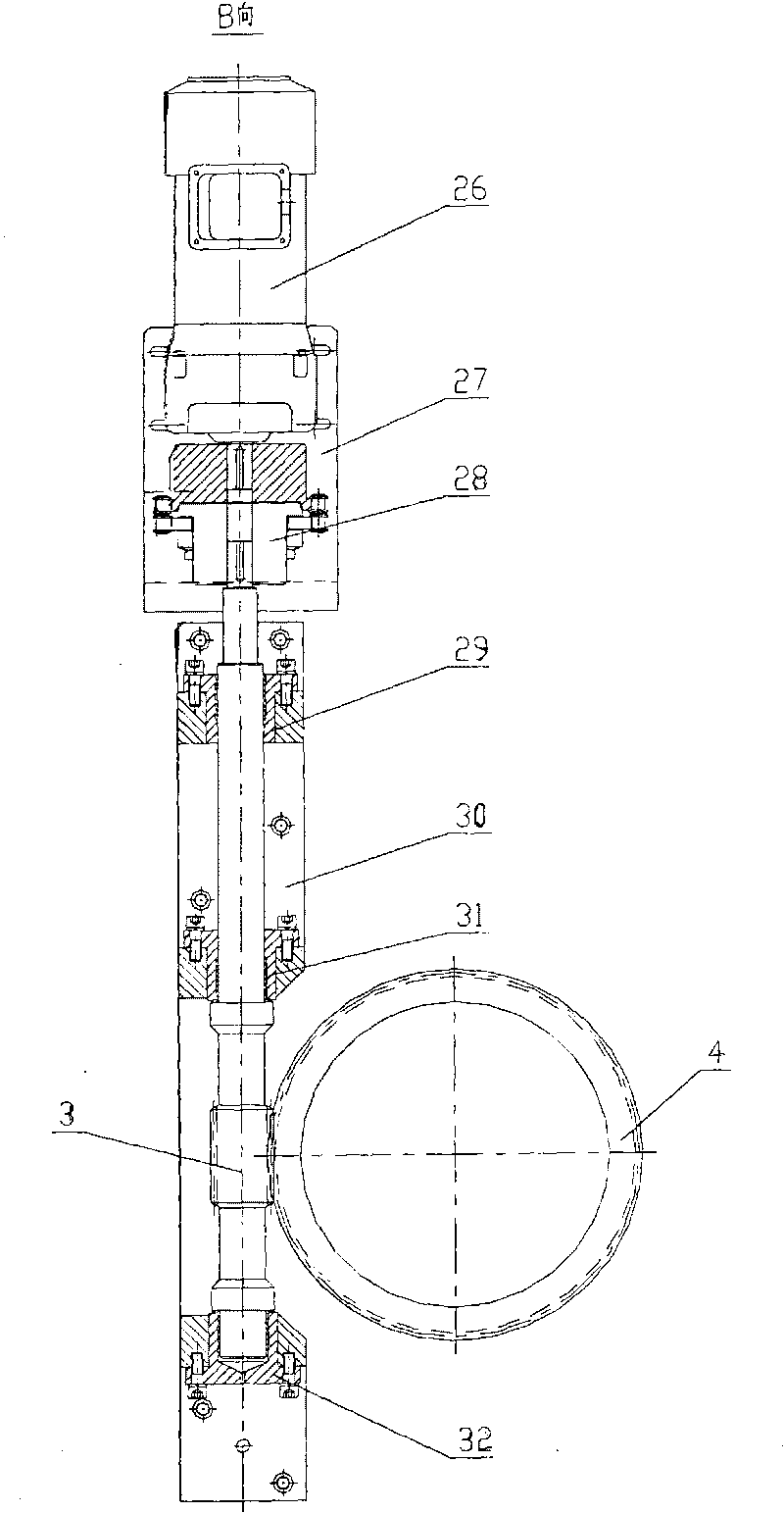

[0025] Refer to attached Figure 1~3 , The structure of the floating core rod cylinder device of the automatic dry powder press includes a worm gear box bottom plate 7, a piston 10, a core rod 12, a cylinder body 11, a cylinder head 9, a core rod stroke adjustment mechanism and a core rod cylinder height adjustment mechanism.

[0026] The cylinder block 11 of core rod cylinder is contained in the lower end of worm gear box base plate 7, and cylinder cover 9 is contained in the upper end of cylinder block 11, and cylinder cover sealing ring is housed between cylinder cover 9 and cylinder block 11. A long screw is installed on the cylinder head 9, and the other end of the long screw is fixed on the lower end of the bottom plate 7 of the worm gear box, thereby forming a core rod cylinder, a core rod 12 is housed in the core rod cylinder, and a piston 10 is installed at the lower end of the core rod 12, and the core rod 12 A core rod sealing ring is arranged between the piston 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com