Finished product bin of dry-mixed mortar station

A technology of dry-mixed mortar and finished product warehouse, applied in the direction of unloading device, etc., can solve the problems of unclean discharge of finished product warehouse, reduce production efficiency, affect product quality, etc., achieve clean discharge, simple structure, wide range The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

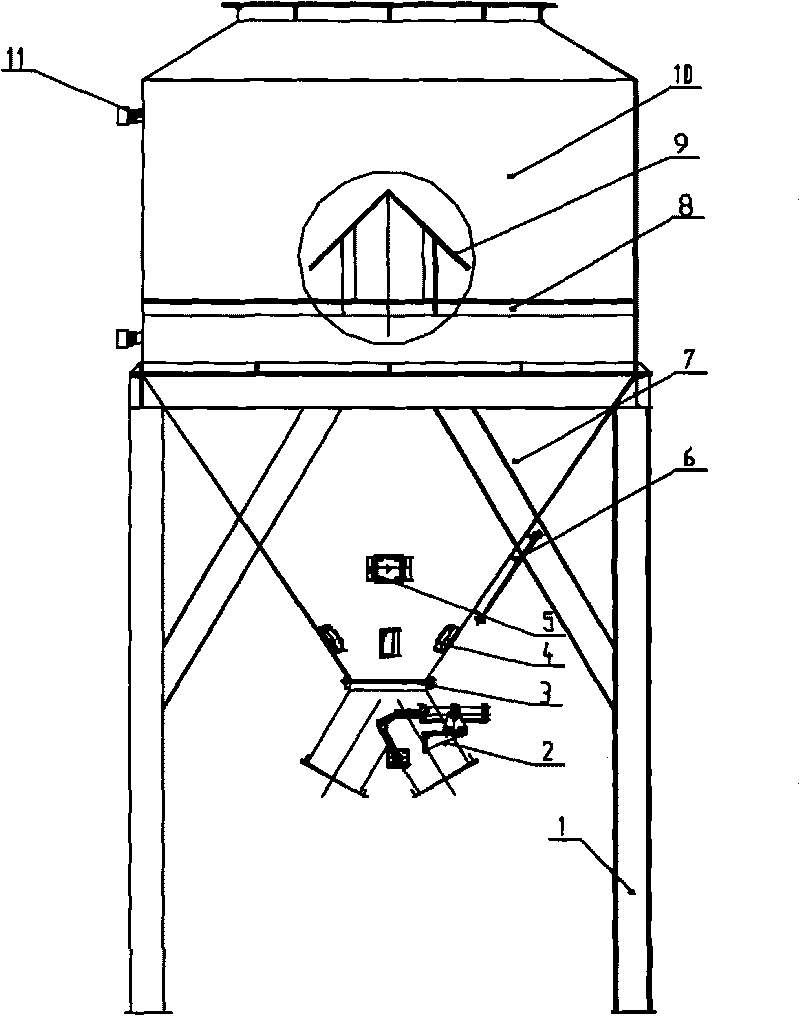

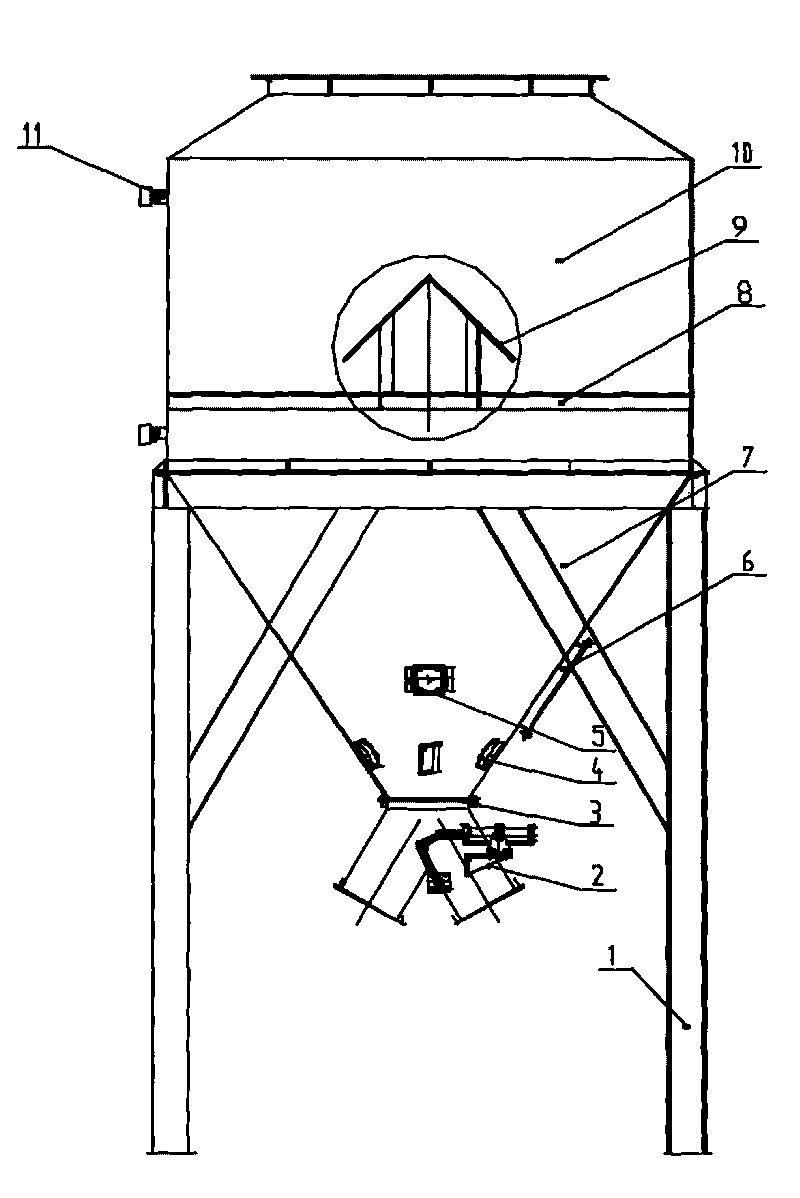

[0010] The finished product warehouse of the dry-mixed mortar station of the present invention is mainly composed of an underframe 1, a pneumatic three-way valve 2, a discharge pipe 3, a flow-aiding air bowl 4, a vibrator 5, a lower warehouse body 7, an upper warehouse body 10, and a level gauge 11 and buffer device. The upper bin body 10 is a square structure welded by 4 steel plates, and its upper part is a conical frustum welded by 4 steel plates, and the four sides of the frustum top are processed with screw holes for connecting with the mixing main engine; the upper bin body 10 A material level gauge 11 is installed at the upper and lower parts, and the lower part of the upper bin body 10 is a flange structure, which is fixedly connected with the bottom frame 1 through the flange. There is a buffer device inside the upper bin body 10, and the buffer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com