Halogen-free soldering flux for electronic industry

A technology for the electronics industry and flux, used in welding media, manufacturing tools, welding equipment, etc., can solve problems such as weak welding performance, and achieve the effect of reducing defects and improving wettability

Inactive Publication Date: 2010-06-16

SICHUAN UNIV +1

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] The purpose of the present invention is to provide a new type of halogen-free soldering flux to overcome the shortcomings of the existing halogen-free products with poor soldering performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-10 and comparative example 1-3

[0034] See Table 1 for the components contained in Examples 1-10 and Comparative Examples 1-3 of halogen-free fluxes for the electronics industry and the content of each component.

[0035] Flux Solderability Evaluation

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

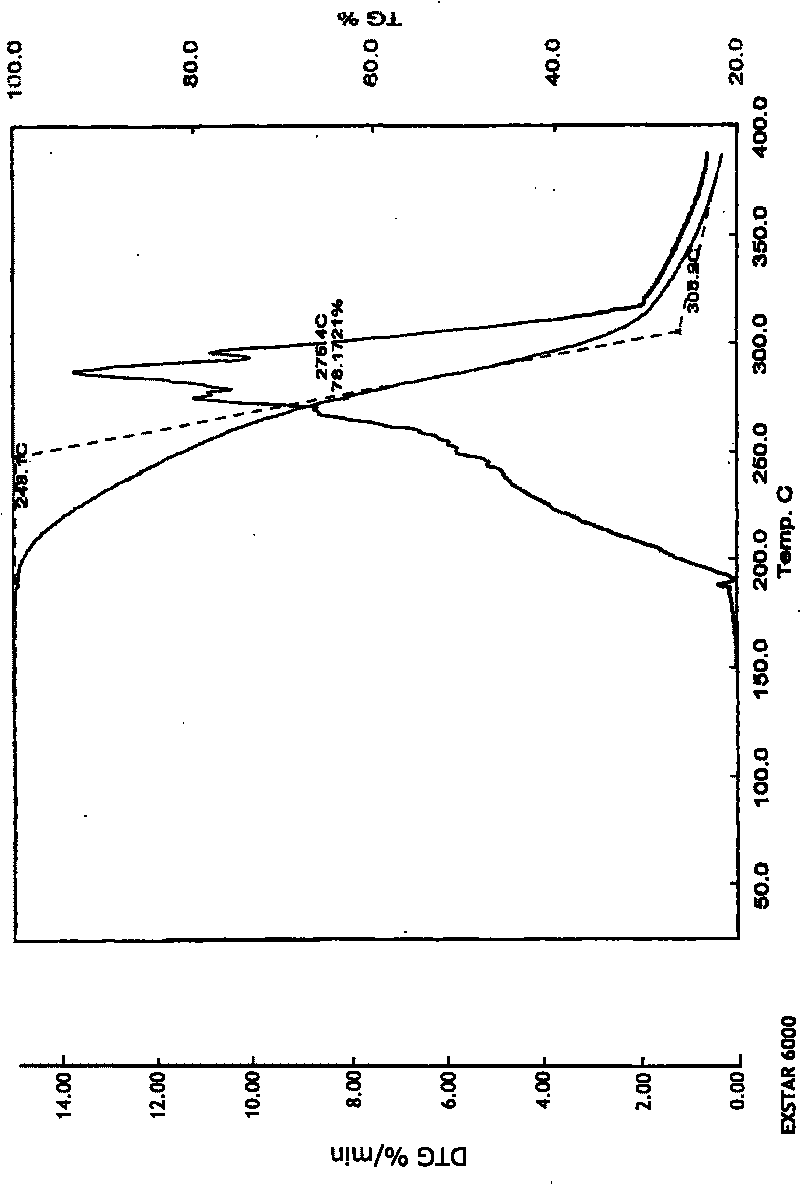

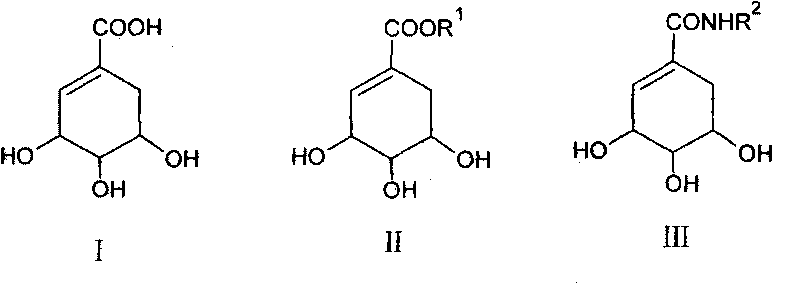

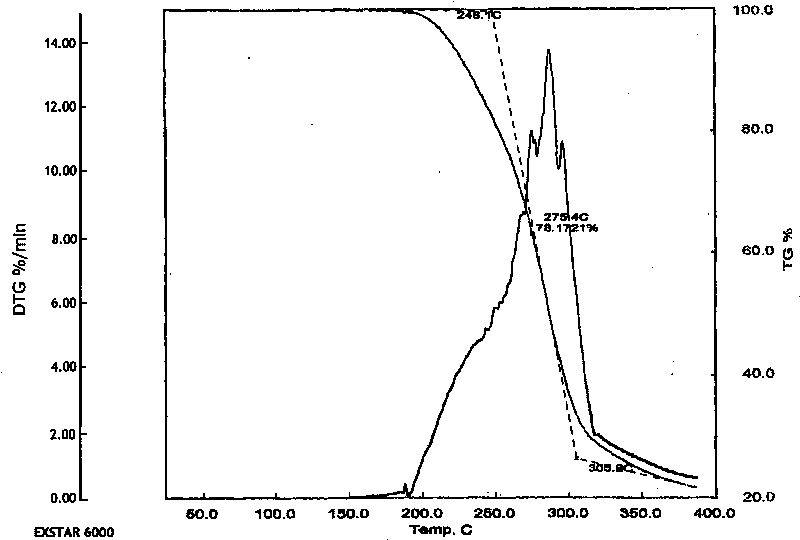

The invention relates to a chemical soldering flux in the electronic industry, in particular to a soldering flux for arranging electronic elements. The technical scheme of the invention is as follows: the soldering flux for electronic industry comprises solvent, resin, activator and surfactant and is characterized in that the activator contains one or more of shikimic acid with the constitutionalformula shown in formula I, shikimate with the constitutional formula shown in formula II and amide of shikimic acid with the constitutional formula shown in formula III. The soldering flux can increase the wettability of the halogen-free product so as to reduce bad effects caused by the solderability of the traditional halogen-free soldering flux in production.

Description

technical field [0001] The invention relates to flux chemicals used in the electronics industry, in particular to fluxes used for installing electronic components. Background technique [0002] The electronics industry needs to install a large number of electronic components on the printed circuit board by soldering. Good and reliable solder joint formation requires wetting, diffusion and metallurgical bonding of molten solder on very clean metal surfaces. However, the possibility of oxidation of printed circuit boards, electronic components, or other metal surfaces that are welded is almost 100% during manufacturing, storage, transportation, and reproduction. Therefore, the treatment of the oxide layer on the surface of the welding material is very critical in the production of the electronics industry. It is often necessary to use a large amount of flux chemicals to clean the oxide layer and pollutants on the metal surface to increase wetting, help and accelerate the weld...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/36

Inventor 黄艳陈群卢志云邓小成郑伟民

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com