Novel continuous casting roller surfacing technology

A continuous casting roll and process technology, applied in the field of surfacing welding, can solve the problems of poor stress state of the weld bead, time-consuming consumables, and difficult quality assurance, so as to avoid residual shear stress, save money and manpower, and eliminate surfacing welding The effect of blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

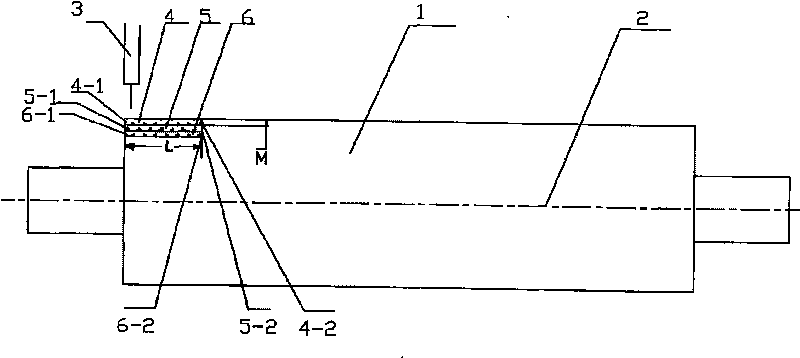

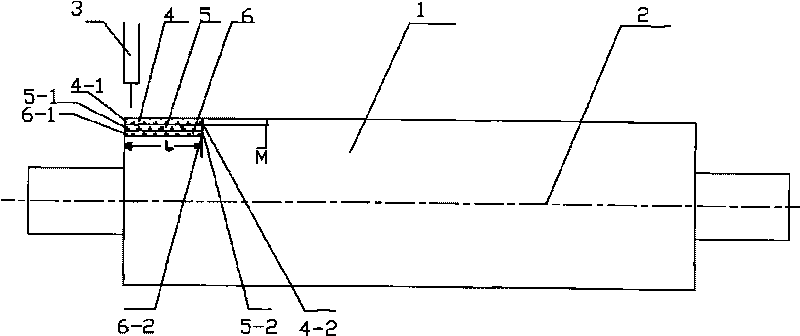

Image

Examples

Embodiment 1

[0033] Continuous casting roll diameter: Φ100mm

[0034] Flux cored wire grade: YSD-414NO

[0035] Flux cored wire specification: Φ2.4mm

[0036] Swing bead length L: 50mm,

[0037] Oscillating frequency: 50 cycles / min,

[0038] Surfacing voltage: 27V,

[0039] Surfacing current: 350A,

[0040] Roller rotation step distance: 2mm,

[0041] Number of surfacing layers: two layers,

[0042] There is no surfacing blind area on the surface of the continuous casting roll, saving time and effort, the surfacing layer is automatically deslagged, no defects, no residual shear stress on the surfacing layer, the continuous casting roll after surfacing has a low fracture probability during use, and is resistant to cold and heat fatigue , high temperature corrosion, strong wear resistance, long service life of continuous casting rolls.

Embodiment 2

[0044] Continuous casting roll diameter: Φ100mm

[0045] Flux cored wire grade: YSD-414NS,

[0046] Flux cored wire specification: Φ2.8mm

[0047] Swing bead length L: 50mm,

[0048] Oscillating frequency: 50 cycles / min,

[0049] Surfacing voltage: 31V

[0050] Surfacing current: 450A,

[0051] Roller rotation step distance: 2.5mm

[0052] Number of surfacing layers: two layers,

[0053] There is no surfacing blind area on the surface of the continuous casting roll, saving time and effort, the surfacing layer is automatically deslagged, no defects, no residual shear stress on the surfacing layer, the continuous casting roll after surfacing has a low fracture probability during use, and is resistant to cold and heat fatigue , high temperature corrosion, strong wear resistance, long service life of continuous casting rolls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com