Hydraulic shear pressing device of aluminium sheet strip rolling mill

A technology of pressing device and hydraulic shear, applied in shearing device, accessory device of shearing machine, metal rolling, etc., can solve the problems of poor cylinder synchronization performance, unsatisfactory use effect, and cylinder stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

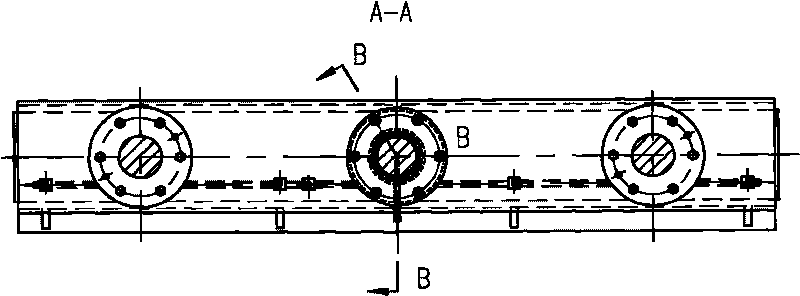

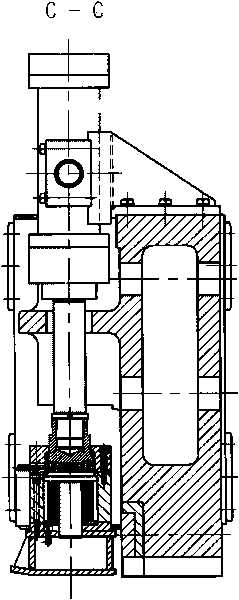

[0019] like figure 1 , 2 , 3, 4, and 5, the hydraulic shearing and pressing device of the aluminum strip rolling mill has an upper tool rest body 2 of a heavy hydraulic shear, and a pressing device is installed on the upper tool rest body; Composed of cylinder 5, guide post 4 and pressure plate 14, the pressure plate is a long structure, so that the contact area between the pressure plate and the strip is large, and the indentation on the surface of the strip is small. The hydraulic cylinder 5 is arranged on the upper tool holder body 2, two The guide posts 4 are respectively arranged on the left and right sides of the hydraulic cylinder 5, and each guide post passes through the guide post hole provided on the upper tool rest body, and the lower end of the guide post is connected with the pressure plate 14 through a flange; the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com