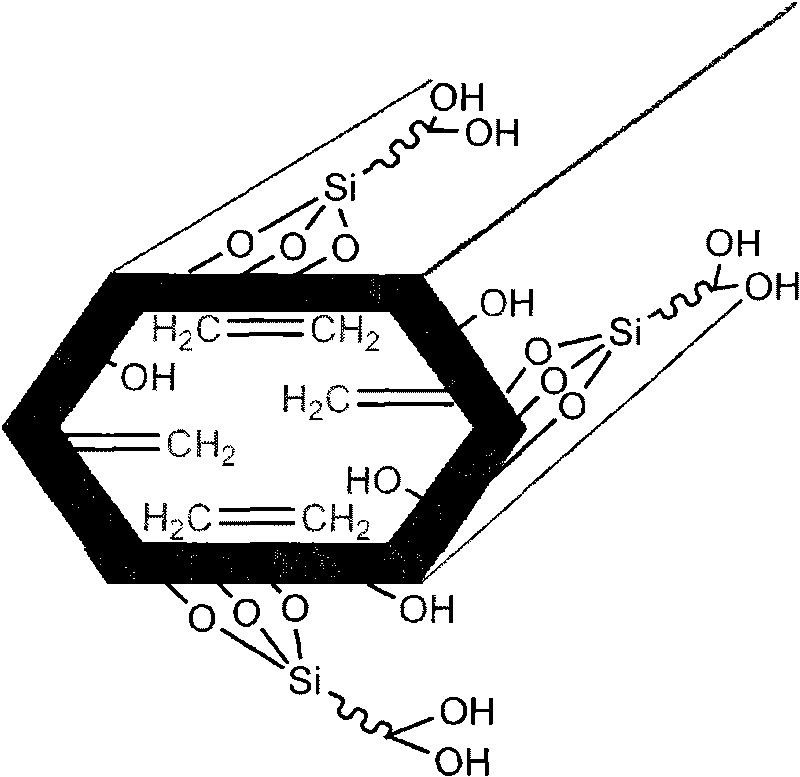

Method for preparing mesoporous material with hydrophobic inner surface and hydrophilic outer surface

A mesoporous material and outer surface technology, applied in chemical instruments and methods, inorganic chemistry, other chemical processes, etc., to achieve the effect of simple method, improved analysis efficiency, improved screening ability and extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

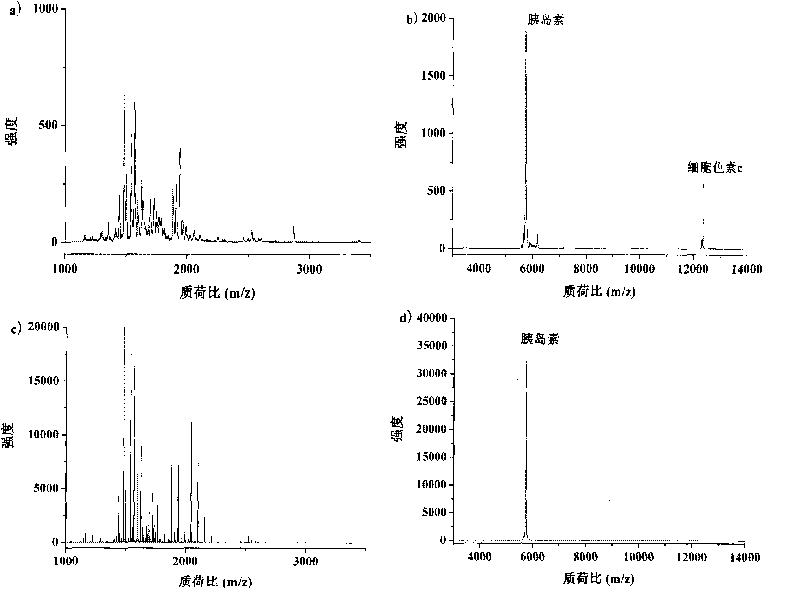

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

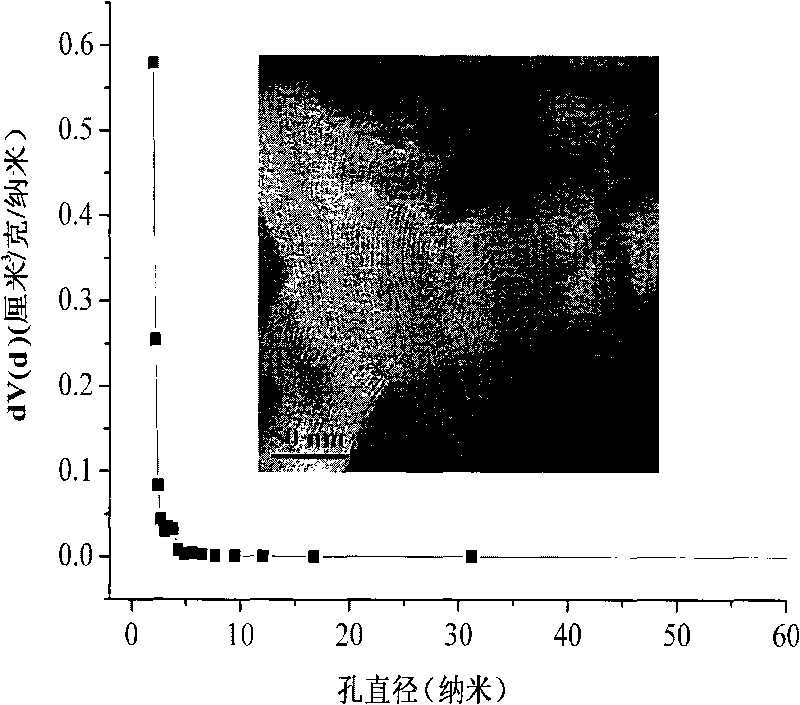

[0022] 1) Co-precipitation synthesis of materials:

[0023] Tetraethoxysilane: vinyltriethoxysilane: hexadecyltrimethylammonium bromide: sodium hydroxide: water is mixed in a molar ratio of 1:0.25:0.15:0.38:125, Hydrothermal reaction at 87°C for 2 days. After filtering, washing and drying the material. (References: Lim, M.H.; Blanford, C.F.; Stein, A.J. Am. Chem. Soc. 1997, 119, 4090.)

[0024] 2) External surface modification:

[0025] External surface modification: 1.0 g of the above-mentioned synthesized powder was vacuum-dried at 90°C for 12 hours, and the dried material containing the pore-forming agent was added to a round-bottomed flask, and 60 mL of dry toluene was added to the flask under nitrogen protection. After the material was completely dispersed in a dry organic solvent, 3mL of 3-(2,3-glycidoxy)propyltrimethoxysilane was added, and reacted at 100°C for 24 hours under the protection of nitrogen. After the reaction, the product was obtained by suction filtrat...

Embodiment 2

[0029] 1) Co-precipitation synthesis of materials:

[0030] Tetraethoxysilane: vinyltriethoxysilane: hexadecyltrimethylammonium bromide: sodium hydroxide: water is mixed in a molar ratio of 1:0.25:0.15:0.38:125, Hydrothermal reaction at 87°C for 2 days. After filtering, washing and drying the material. (References: Lim, M.H.; Blanford, C.F.; Stein, A.J. Am. Chem. Soc. 1997, 119, 4090.)

[0031] 2) External surface modification:

[0032] External surface modification: 2.0g of the above-mentioned synthesized powder was vacuum-dried at 80°C for 15 hours, the dried material containing the pore-forming agent was added to a round-bottomed flask, and 100mL of dry cyclohexane was added to the flask under nitrogen protection. After the material was completely dispersed in dry cyclohexane, 6 mL of 3-(2,3-epoxypropoxy)propyltrimethoxysilane was added, and reacted at 60°C for 24 hours under nitrogen protection. After the reaction, the product was obtained by suction filtration, washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com