Positively charged composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane, positively charged technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complicated preparation steps, difficult to control membrane structure and performance, etc., and achieve a simple and safe preparation process. , low price, easy to obtain the effect of monomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

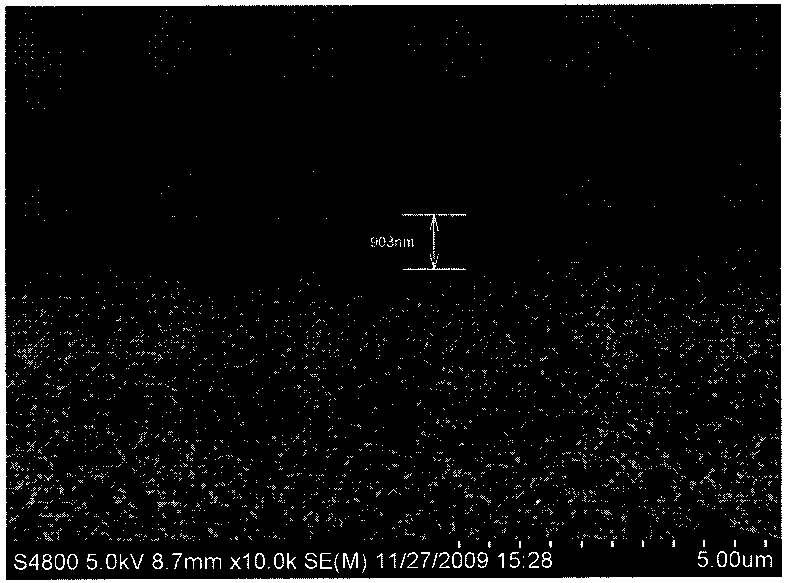

Image

Examples

Embodiment 1

[0017] Add 2 parts by mass of N,N-dimethylaminoethyl methacrylate and 1 part by mass of hydroxyethyl acrylate to water to form an aqueous solution with a mass percent concentration of 10wt%, feed nitrogen gas, and add a mass percent concentration of 1 wt% of water-soluble redox initiator K 2 S 2 o 8 and NaHSO 3 (1:1), solution polymerization was carried out at 35°C, the polymerization time was 24 hours, the polymer was precipitated with acetone, and after repeated washing, a cationic copolymer was obtained, which was dried in vacuo for subsequent use; 1 mass part of the copolymer and 0.1 parts by mass of glutaraldehyde were added to water, and sulfuric acid was added to adjust the pH of the solution to be 2; stirred at a temperature of 20°C for 3 hours, and left to stand for 8 hours to obtain a uniform and transparent solution; at a temperature of 20°C and Under the condition of 50% air relative humidity, the above solution is evenly coated on the polysulfone ultrafiltratio...

Embodiment 2

[0019] Add 5 parts by mass of N,N-dimethylaminoethyl methacrylate and 1 part by mass of hydroxyethyl acrylate to water to form an aqueous solution with a mass percent concentration of 30wt%, feed nitrogen gas, and add a mass percent concentration of 3 wt% of water-soluble redox initiator K 2 S 2 o 8 and NaHSO 3 (1:1), solution polymerization was carried out at 50°C, the polymerization time was 8 hours, the polymer was precipitated with acetone, and after repeated washing, a cationic copolymer was obtained, which was dried in vacuum and set aside; 2.5 parts by mass of the copolymer and 0.45 parts by mass of glutaraldehyde were added to water, and sulfuric acid was added to adjust the pH of the solution to be 4; stirred at a temperature of 30°C for 3 hours, and left to stand for 12 hours to obtain a uniform and transparent solution; at a temperature of 30°C and Under the condition of 60% relative air humidity, the above solution is evenly coated on the polysulfone ultrafiltra...

Embodiment 3

[0021] Add 3 parts by mass of N,N-dimethylaminoethyl methacrylate and 1 part by mass of hydroxyethyl acrylate to water to form an aqueous solution with a mass percent concentration of 15wt%, feed nitrogen gas, and add a mass percent concentration of 2 wt% of water-soluble redox initiator K 2 S 2 o 8 and NaHSO 3 (1:1), solution polymerization was carried out at 45°C, the polymerization time was 12 hours, the polymer was precipitated with acetone, and after repeated washing, a cationic copolymer was obtained, which was dried in vacuo for subsequent use; 1 mass part of the copolymer and 0.19 parts by mass of glutaraldehyde were added to water, and then hydrochloric acid was added to adjust the pH value of the solution to 3; stirred at a temperature of 25°C for 3 hours, and left to stand for 8 hours to obtain a uniform and transparent solution; at a temperature of 25°C and Under the condition of 55% relative air humidity, the above solution is evenly coated on the polysulfone u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com