Edge contact clamping type wafer end actuator

An end-effector and edge-contact technology, applied in semiconductor/solid-state device manufacturing, electrical components, surface-polished machine tools, etc., can solve the problems of particle contamination on the back of the wafer, wafer shedding, economic loss, etc., and achieve a simple structure, The effect of reducing equipment cost and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

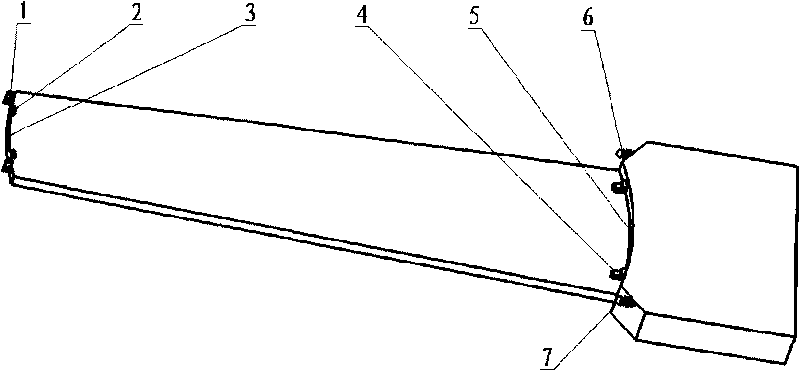

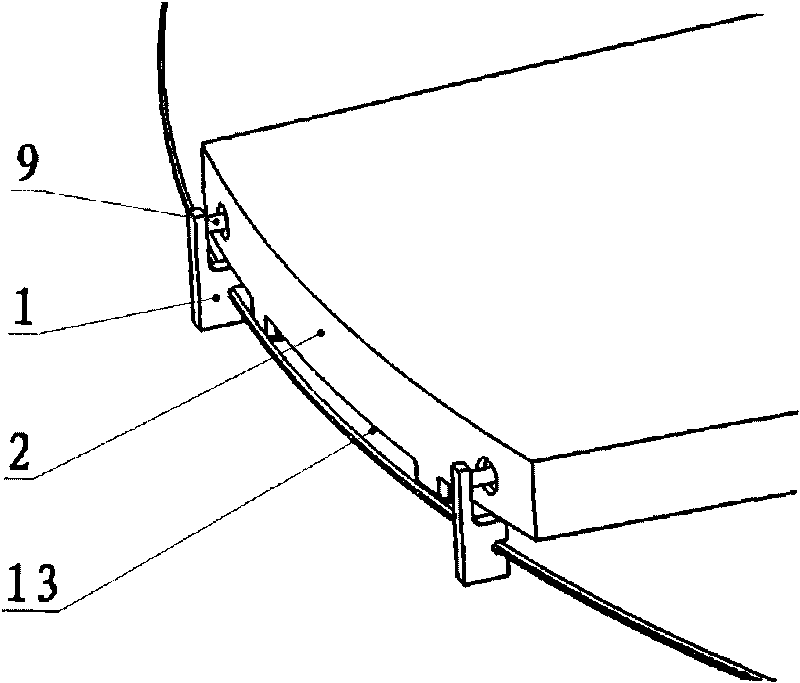

[0025] see Figure 1 to Figure 5 The structure of the edge contact clamping type wafer end effector is as follows: it has a wafer seat 2, and the wafer seat 2 is provided with two edge contact clamping finger hooks 1, the edge contact clamping finger hook 1 and The finger hook telescopic device is connected; the finger hook is provided with a notch shape corresponding to the shape of the wafer; the finger hook telescopic device has the following structure: one end of the spring is fixed on the wafer seat 2, and the other end is installed on the magnetic plate 11, and the magnetic The suction plate 11 is connected to the edge-contact clamping finger hook 1 through the telescopic guide rod 9 , and an electromagnet 10 is provided on one side of the magnetic suction plate 11 . The spring is a tension spring 12, and the electromagnet 10 is located on the other side of the magnetic plate 11, and is provided with a spring pressure regulator 14 (which may be a nut). Wafer contact pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com